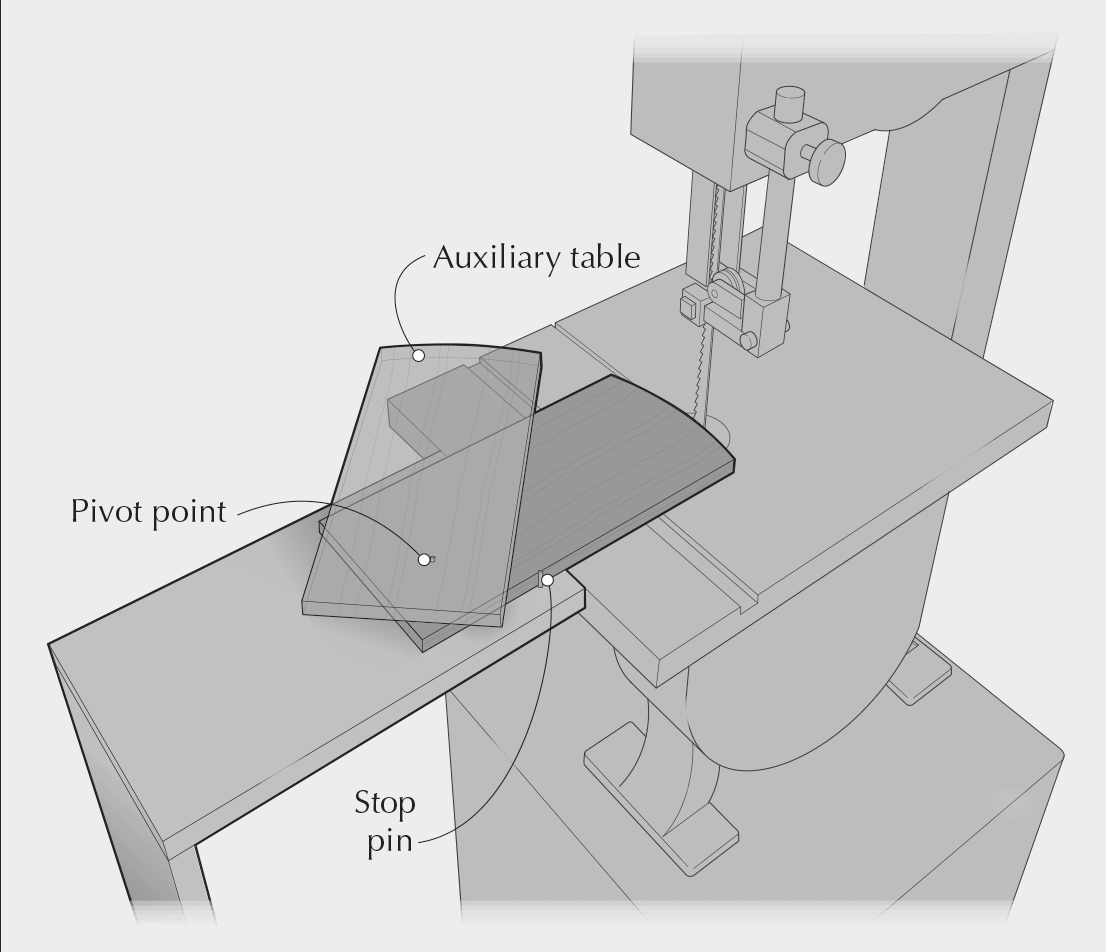

Band Saw Circle Guide

Bleaching Wood

A Sharp Honing Stone Station

Micro-Adjust Fence

Build a Knockdown Shave Horse

Wood Finishing

Hand Tool Techniques

Joinery

Sawing Techniques

Workshop Tips

Marking and Measuring

FREE Project Plans

Join our email list and download your choice of 7 plans instantly. Plus get Popular Woodworking’s top projects and tips, special offers and product news.