We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

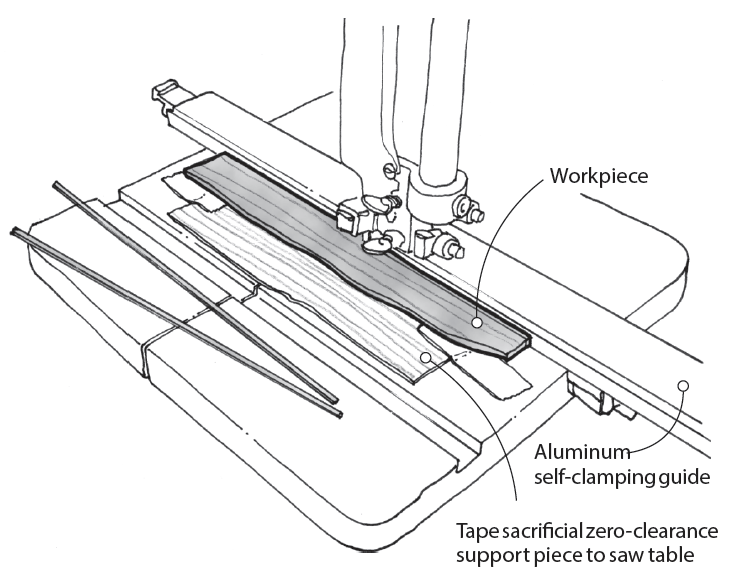

As a guitar maker, I rip a lot of very narrow wood strips, which can be difficult and dangerous to cut on a table saw. Instead, I cut them on the band saw using a low-profile fence, which allows setting the upper blade guides as close as possible to the stock to prevent blade deflection, and increases accuracy. It also allows my fingers better access for feeding the stock. For convenience and quick setup, I use a commercial self-clamping aluminum tool guide. If necessary, it can be angled up to 5˚ or so to accommodate band saw blade drift.

Using a sharp six teeth-per-inch blade, I find that I can accurately rip pieces as narrow as about 1⁄32“, with tolerances to within about .002”. To prevent the narrow rippings from falling down into the throat plate, I feed the stock on top of an underlying sacrificial zero-clearance piece that I tape to the saw table. –Bil Mitchell

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.