We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Q & A: One Step at a Time

Q:

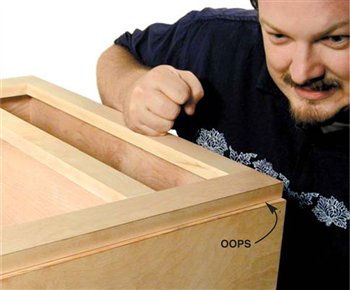

ARGH! I cut all the parts according to the cutting

list and my face-frame came up short! I worked out the

math and the cutting list was correct. What went wrong?

A:

Rule number one when building complex projects

directly from a set of plans: Don’t cut every part at once!

If you cut and fit as you go, your project is bound to work

out.Also, if there is an error in a plan, you’ll likely spot it

before it’s too late.

The problem with completely trusting a cutting list has

to do with the fact that one small discrepancy affects the

dimensions of subsequent parts. Maybe the fence on your

tablesaw was off by a hair and your shelves were a bit long

or maybe your 1/4-in.-deep dadoes were a little shallow.

These small differences can add up to a carcass that’s too

wide for the face frame dimension that’s specified in the

plan. The solution is to build complex projects as a series

of components and to cut and fit the rest of the project to

what’s already been built. In your case, cutting and dry fitting

the plywood box first, then measuring to see what size

the face frame really needed to be would’ve saved you

time,material and aggravation.

|

This story originally appeared in American Woodworker October 2001, issue #89. |

|

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.