We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Like most planers, mine snipes, overcutting a bit at both ends of a board. Sometimes I’ll simply cut off the sniped areas if I can afford the extra board length. However, with precious woods, that can mean trashing a few bucks. Another technique is to closely precede and follow the board with a scrap of the same thickness. But that requires the right scrap and I find the process clumsy, especially when making several passes. Here’s a better approach that only takes a few minutes to set up:

Like most planers, mine snipes, overcutting a bit at both ends of a board. Sometimes I’ll simply cut off the sniped areas if I can afford the extra board length. However, with precious woods, that can mean trashing a few bucks. Another technique is to closely precede and follow the board with a scrap of the same thickness. But that requires the right scrap and I find the process clumsy, especially when making several passes. Here’s a better approach that only takes a few minutes to set up:

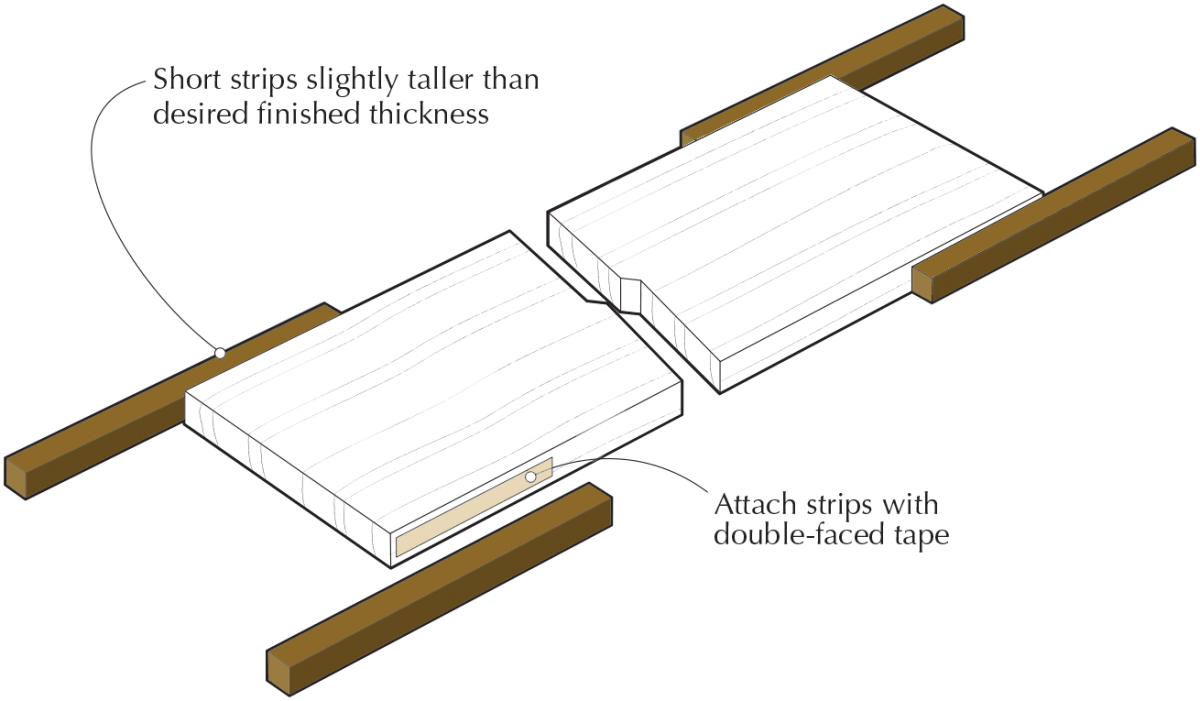

First, joint one face of your board and both its edges. Rip some lengths of straight scrap about 10″ long and just a bit taller than the desired finished thickness of the board. Working on a flat surface, attach the strips to the edges of the board at both ends using double-faced tape. Extend the scraps beyond the ends of the board about 4″, then clamp the strips to the board for a few moments to ensure a good tape bond. Now when you feed the board through the planer, the scrap will take the snipe instead of your stock.

The same principle allows safe feeding of short workpieces. Simply tape the workpiece to long scrap “runners” in the same fashion. But in this case, make sure that the runners start off at least as thick as the stock so the whole assembly will be pulled safely through the planer. — Paul Anthony

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.