We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

When mortising I found it difficult to remove waste left at the bottom of the mortise by my hollow-chisel mortising bit. Prying it out with a bench chisel often damaged the shoulder of the mortise and was not kind to the cutting edge of the chisel. I needed a tool with a right-angle cutting edge that would allow me to scrape the bottom of the mortise right up to the corners, then pull the chips out. I figured out how to make one from a 7⁄32″ Allen wrench. Here’s how:

When mortising I found it difficult to remove waste left at the bottom of the mortise by my hollow-chisel mortising bit. Prying it out with a bench chisel often damaged the shoulder of the mortise and was not kind to the cutting edge of the chisel. I needed a tool with a right-angle cutting edge that would allow me to scrape the bottom of the mortise right up to the corners, then pull the chips out. I figured out how to make one from a 7⁄32″ Allen wrench. Here’s how:

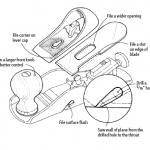

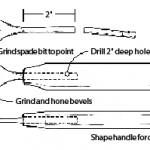

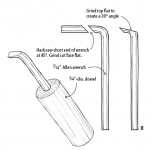

With a hacksaw, cut the short leg off at a 45° angle, leaving about 3⁄4″ of length on that leg, then grind the face of the cut flat. Next, grind the top of the short leg flat to create a 30° cutting edge at the intersection with the first cut. The exact angle isn’t critical. You just want it sharp enough to cut well, but sturdy enough to withstand the prying action. Go easy with the grinding, cooling the metal frequently in water. If you overheat it while grinding, it will lose its temper and your tool will dull quickly in use.

For a handle, drill a 3⁄16″ hole at least 1″ deep in a piece of 3⁄4″-diameter hardwood dowel, then tap the Allen wrench into the hole. This tool works well for cleaning mortise slots 1⁄4″ wide and up. For larger mortises make one with a larger Allen wrench.

– Mike Callihan

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.