We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

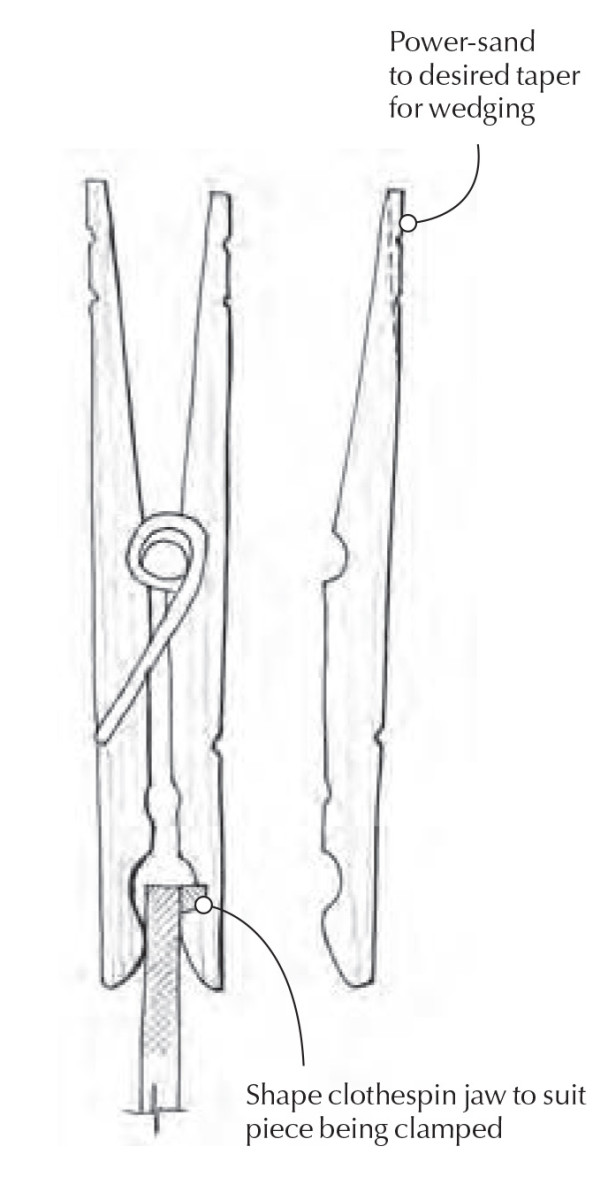

When working on small projects, I often need to glue odd-shaped mouldings and tiny trim to box sides and other pieces. Not much pressure is required to hold these small pieces in place, and I find that the humble wooden clothespin is often the perfect clamp for the job. Cheap and easily available, spring clothespins are easily tailored for custom clamping. For example, when gluing moulding to the edge of a piece of wood, one jaw of the clothespin can be filed, sanded or sawn to fit the profile of the moulding while the other jaw can be tapered parallel to the first. This applies consistent clamping pressure across the width of the moulding.

As an added benefit, disassembling a spring clothespin quickly yields a couple wedges, which can also be helpful for shimming during some gluing operations. The tapered end can be easily modified with a sander or other woodworking tool to whatever suitable taper is needed for the application. — Barry Sleepwell

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

By reversing the wooden pieces (inside, out) you create a “close” pin from a clothes pin. The tapered end become the clamp surface for close work.