We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

While making Shaker boxes, I built a jig to accurately rip 1/16″ thick strips without getting my hands too close to the blade. In fact, I can leave the guard on the saw.

The jig has two parts. First, there’s a track that mounts on the saw, next to the fence. Two rare-earth magnets recessed into the bottom of the track keep it from sliding. The track is positioned 1/16″ away from the blade, or at whatever thickness of strip I want to rip.

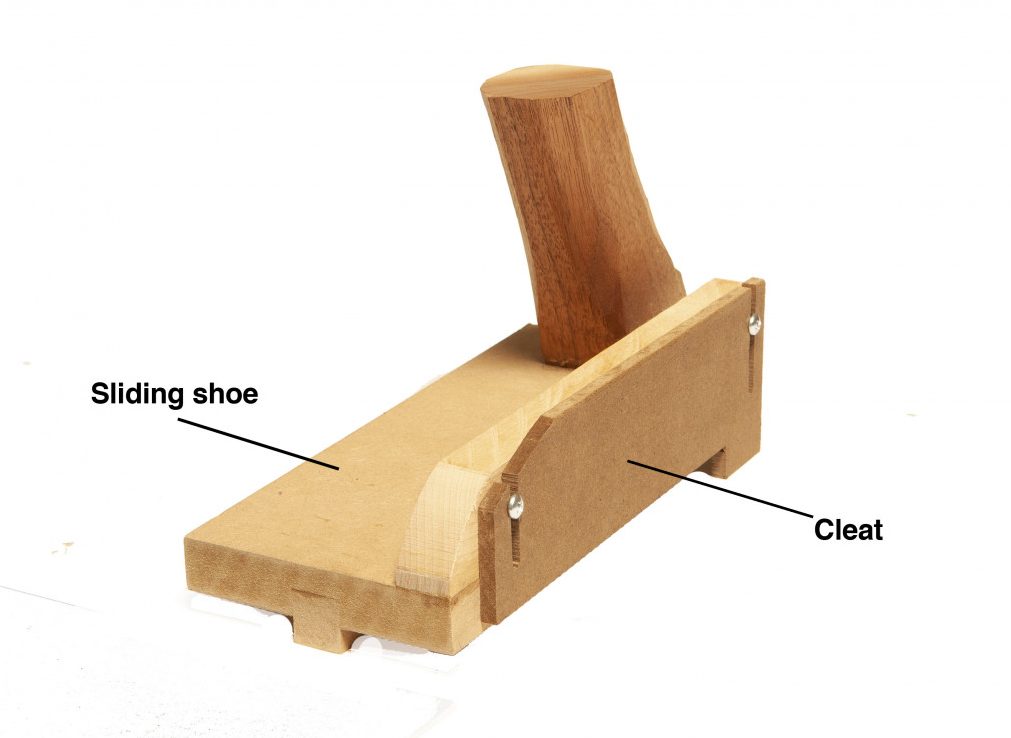

The second part of the jig is a push block. (I call it a shoe.) It slides in a groove on the track. The shoe has a 1/8″ thick sacrificial cleat that hooks over the back end of the board I’m ripping. The cleat has slots in it, so I can move it up or down to accommodate boards of different thicknesses.

The second part of the jig is a push block. (I call it a shoe.) It slides in a groove on the track. The shoe has a 1/8″ thick sacrificial cleat that hooks over the back end of the board I’m ripping. The cleat has slots in it, so I can move it up or down to accommodate boards of different thicknesses.

To cut a strip, I put a magnetic featherboard on the left side of the board I’m ripping to keep the board tight against the track. Then I feed the board into the saw by hand, just like any other rip cut.

When the end of the board is even with the track, I put the shoe on the track and push the board the rest of the way through the cut. The front edges of the shoe and cleat are rounded to allow the blade guard to ride up and over the jig. –Joe Scharle

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.