We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

I make my own zero-clearance throat plates for my table saw to minimize exit tear-out on workpieces and to prevent narrow pieces from dropping into the saw. When raising the blade through the insert blank for the first time (using a small-diameter blade), it’s necessary to hold the insert down for safety. I used to do this by clamping a stout board across the insert and the saw table, with the board parallel to the blade and off to its side. But, this is inconvenient because my outfeed table impedes clamping at the rear of the saw. I recently discovered a better way, putting to use Popular Woodworking Books Editor David Thiel’s suggestion that a T-nut can be used to secure jigs in a typical machine table T-slot.

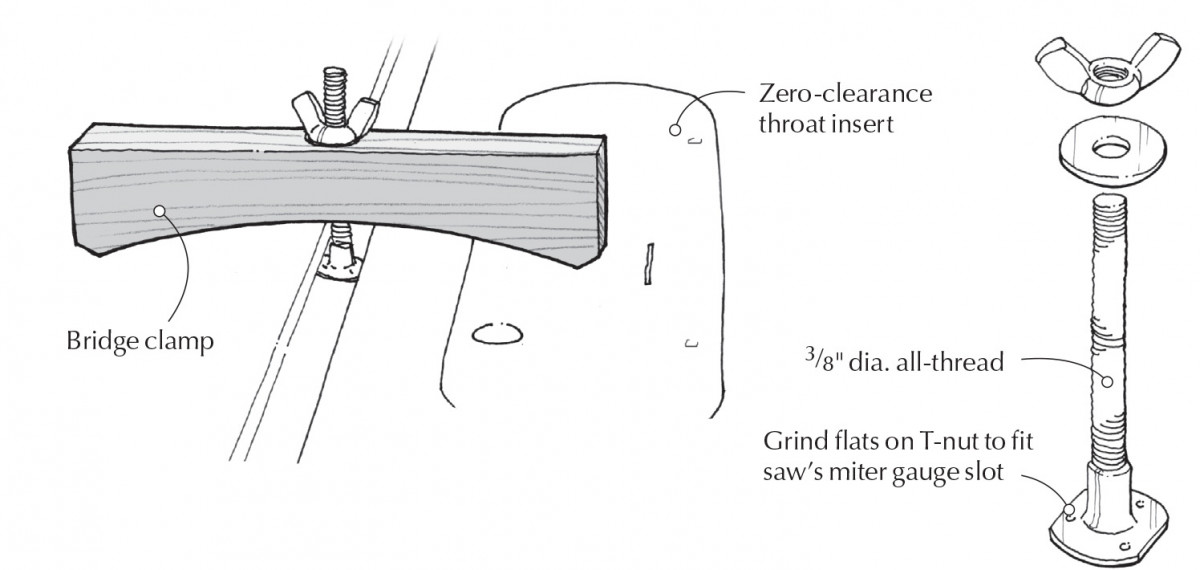

To make a bridge clamp for holding the throat insert in place, I first drilled a 7⁄16“-diameter hole through the center of a short length of 3⁄4” x 13⁄4” hardwood. I then cut an arch on the underside of the piece, shaping a slight return on the ends as shown in the drawing. After grinding the edges of a 3⁄8” barb-less T-nut to fit my saw’s miter gauge T-slot, I inserted a 3″ length of 3⁄8“-diameter all-thread into it. (You could instead use a bolt with the head cut off). A wing nut and washer complete the clamp. Obviously, you could use this basic concept to make your own featherboards and other hold-downs as well. — Paul Anthony