We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

While turning wooden pens, students in my woodshop classes kept wearing out the points on the live centers of our mini lathes. The points fit into the hollowed end of the pen mandrel. If the mandrel isn’t clamped tight enough between the lathe’s head and tailstock, it spins on the point and wears it out. A worn-out point allows the mandrel to wobble and makes it impossible to turn the pen blanks.

While turning wooden pens, students in my woodshop classes kept wearing out the points on the live centers of our mini lathes. The points fit into the hollowed end of the pen mandrel. If the mandrel isn’t clamped tight enough between the lathe’s head and tailstock, it spins on the point and wears it out. A worn-out point allows the mandrel to wobble and makes it impossible to turn the pen blanks.

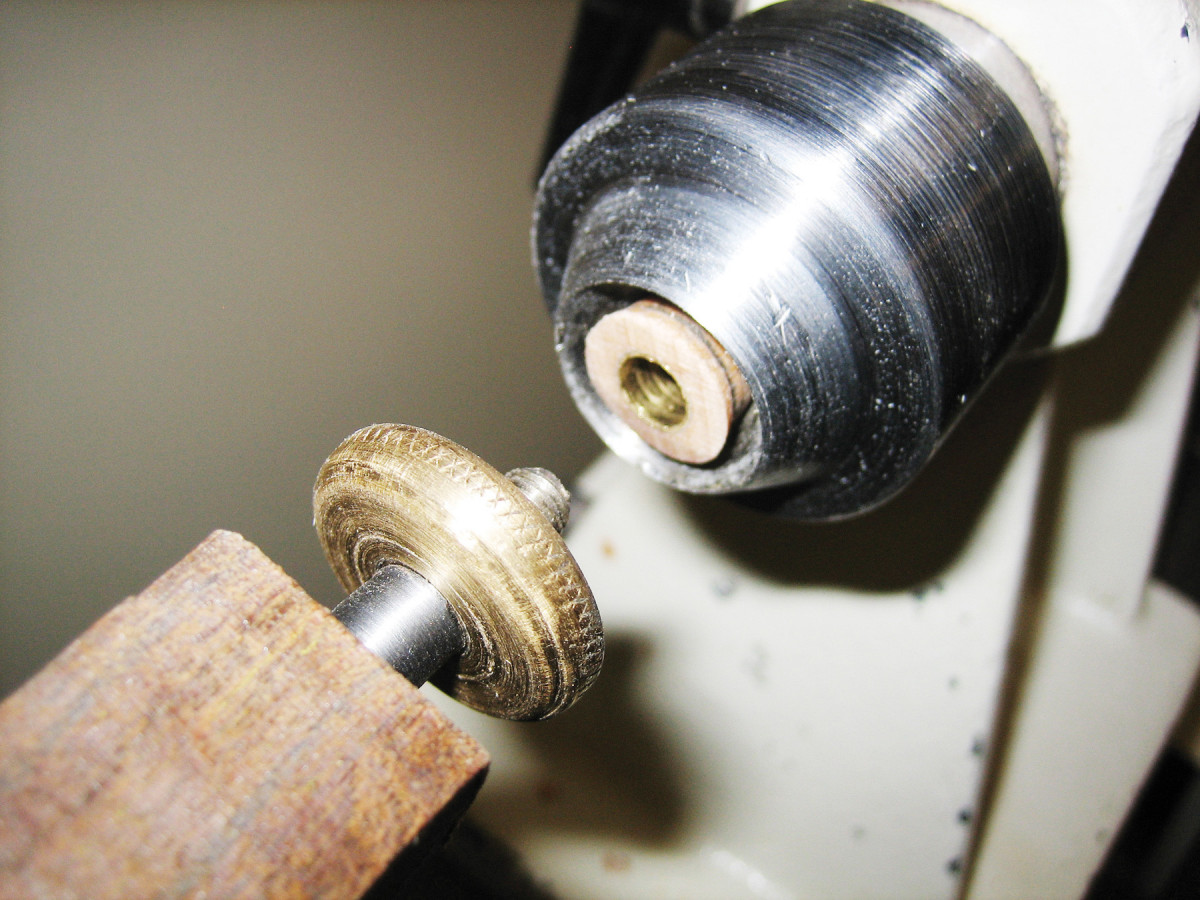

To keep the classes running smoothly, I had to solve the problem right away. So I removed the wornout points and installed wooden plugs tapered to fit inside the lathes’ live centers.

To keep the classes running smoothly, I had to solve the problem right away. So I removed the wornout points and installed wooden plugs tapered to fit inside the lathes’ live centers.

Each plug contains a brass pen sleeve that perfectly houses the mandrel. These plugs worked great. They’d be perfect for occasional use, but my shop classes required a more permanent solution.

Each plug contains a brass pen sleeve that perfectly houses the mandrel. These plugs worked great. They’d be perfect for occasional use, but my shop classes required a more permanent solution.

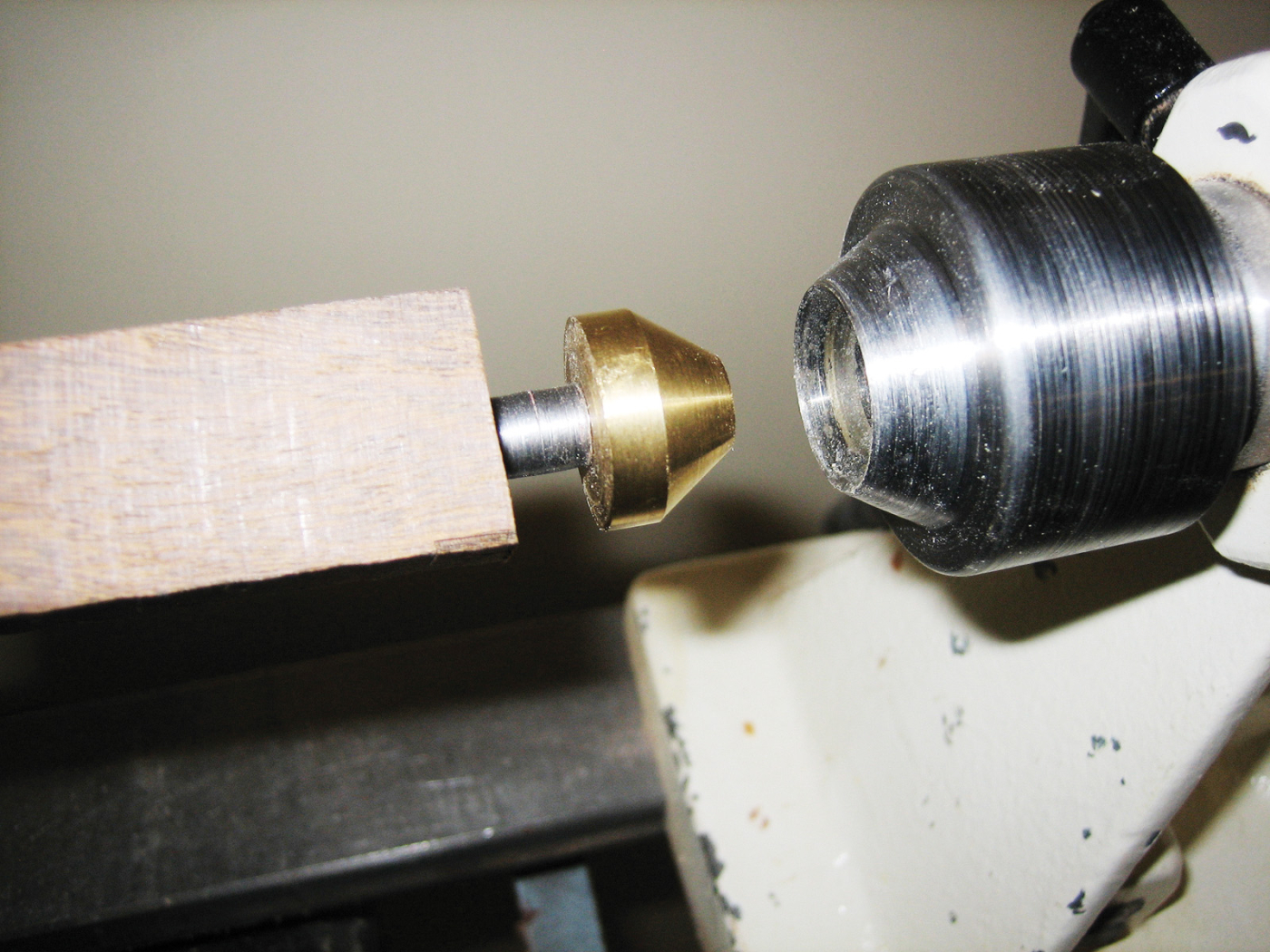

I had a machinist friend make these cone-shaped brass nuts that thread onto the mandrel. The cone shape matches the live center’s large tapered opening. This nut installs easily and centers itself every single time. -Tom Bockman

I had a machinist friend make these cone-shaped brass nuts that thread onto the mandrel. The cone shape matches the live center’s large tapered opening. This nut installs easily and centers itself every single time. -Tom Bockman

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.