We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

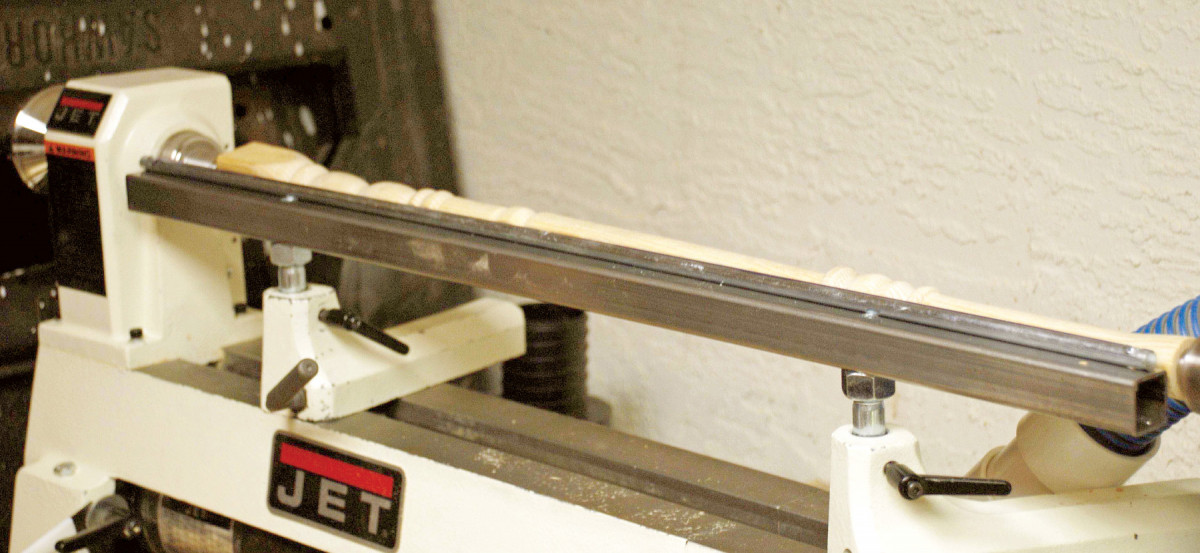

For turning spindles, there’s nothing like having a really long tool rest. You never have to move it! I made my own with parts from the hardware store.

This rest is just a length of square steel tubing with a steel rod fastened to its top. The rod’s rounded surface makes it easy to slide your tools back and forth. The rest has two 5/8″ dia. posts—like most factory-made long tool rests. You’ll need to buy an extra cross slide for mounting the second post.

To make the tool rest, cut the tube and the rod to the desired length. Drill a 5/8″ hole near each end of the tube.

Shopping List: • Two 5/8″ x 4″ hex-head bolts • One piece of 1″ square steel tubing • One piece of 3/8″ round steel rod • Four 5/8″ nuts • A handful of 3/4″ 8-32 flat-head machine screws.

Using a drill press, drill 1/8″ dia. holes every 4″ to 5″ along the rod’s length. Support the rod with a V-block and use a fence to make sure the holes stay in line. Counterbore each hole to accept the 8-32 screw heads.

Clamp the rod in position on the tube, about 1/8″ from the front edge (the edge that will be nearest the spindle). Drill through the rod’s holes into the tube. Tap the tube’s holes for the 8-32 screws. Screw the rod to the tube. Fill the counterbored holes with epoxy to create a smooth bearing surface.

Two of the 5/8″ nuts slide into the tube to receive the posts. You’ll have to file or grind down two faces on these nuts so they will fit. To make the posts, cut off the heads of two 5/8″ x 4″ bolts; file off any sharp edges. Thread a jam nut onto each bolt and insert the bolt into the tube. Thread the bolt into the interior nut, then tighten the jam nut. –Irwin Rappaport

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.