We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

A lot of folks use a stone to put the final edge on a scraper before turning its hook, but I prefer to use a diamond paddle. It cuts faster than most stones and obviously won’t develop a rut, which is always a danger when you continually run the edge of a scraper on a stone.

A lot of folks use a stone to put the final edge on a scraper before turning its hook, but I prefer to use a diamond paddle. It cuts faster than most stones and obviously won’t develop a rut, which is always a danger when you continually run the edge of a scraper on a stone.

I use an extra-fine diamond paddle, which is roughly equivalent to a soft Arkansas oilstone or a 1000 grit waterstone. While the diamond can’t make a scraper’s edge quite as sharp as a very fine stone, the edge is good enough for all but the most demanding work. I lubricate the paddle with some 3-in-1 oil to float away the metal debris, so it won’t clog the paddle.

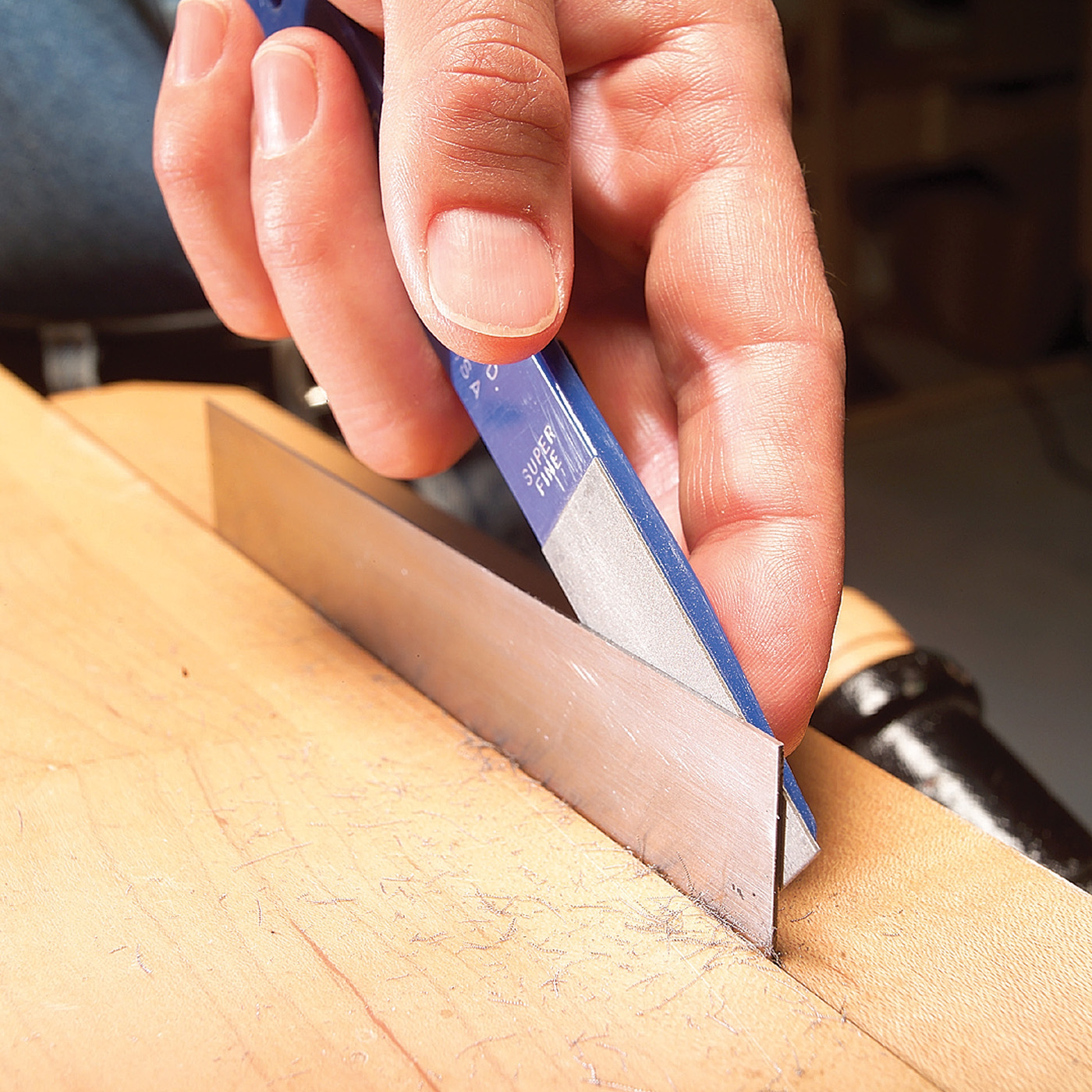

To hone the scraper’s edge, I position the scraper in a vise so that it’s level with a small stick. Resting the paddle on the stick ensures that the scraper’s edge will be exactly 90° (Photo 1). I also use the paddle to remove the wire edge formed by honing (Photo 2).

To hone the scraper’s edge, I position the scraper in a vise so that it’s level with a small stick. Resting the paddle on the stick ensures that the scraper’s edge will be exactly 90° (Photo 1). I also use the paddle to remove the wire edge formed by honing (Photo 2).