We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

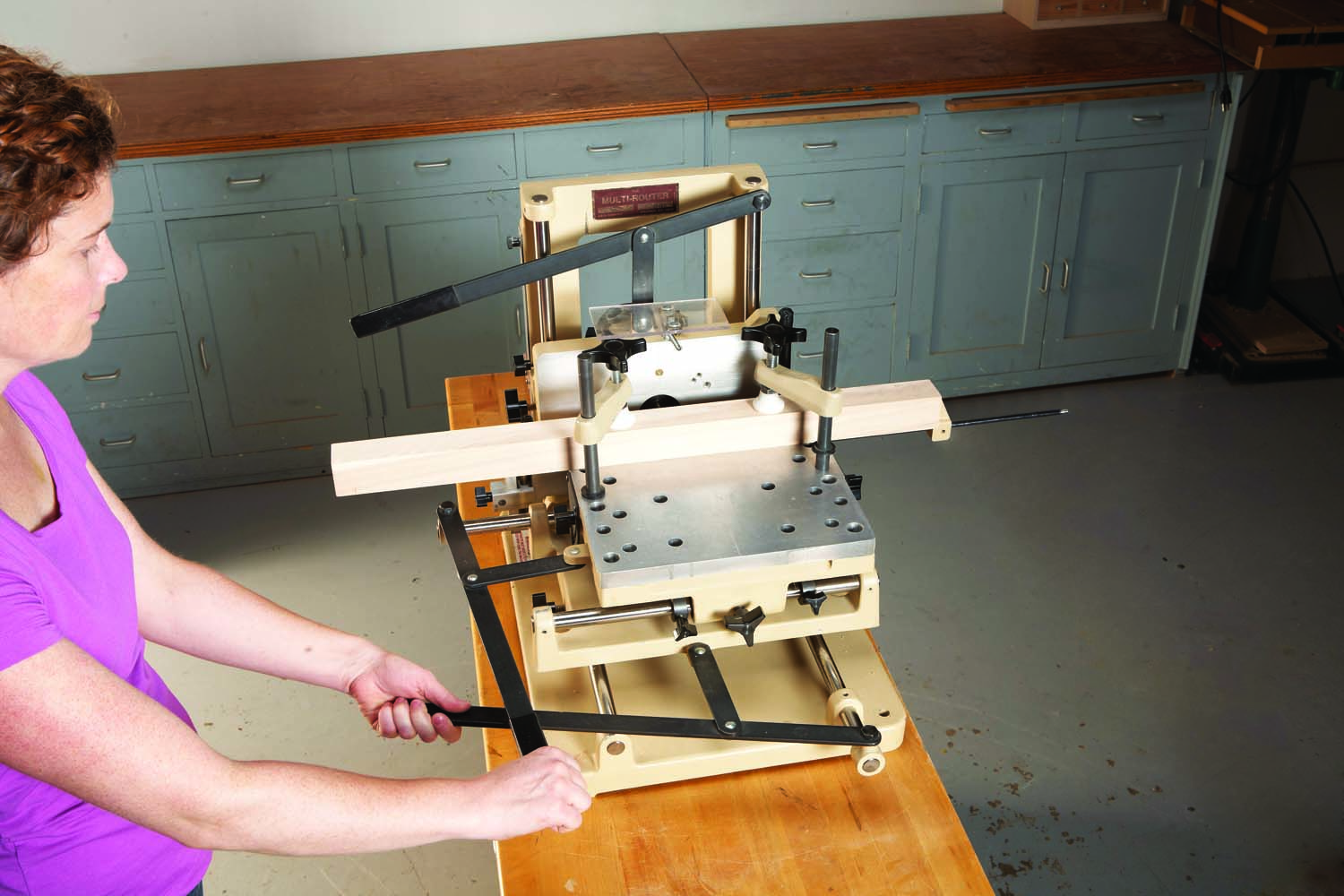

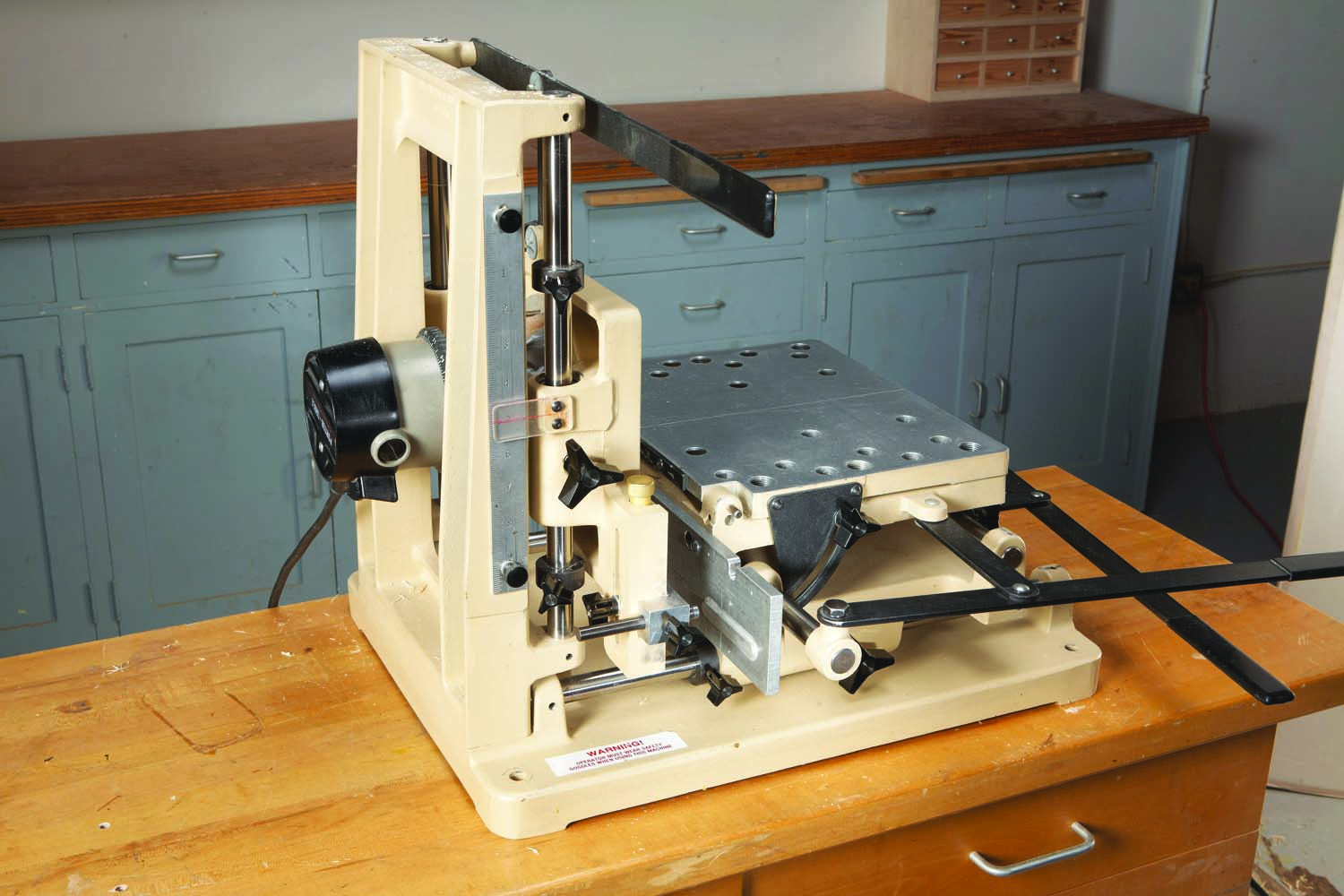

The author’s JDS Multi-Router at work

The JDS Multi-Router recently passed its 25th anniversary. In all those years, there’s been only one relatively minor change to this venerable joint-making machine—a remarkable feat when you consider how frequently woodworking tools are upgraded or redesigned. The Multi-Router can be used to cut dovetails and many other useful woodworking joints, but it excels at cutting mortises and tenons. As a furniture maker and a member of a co-operative shop that has three Multi-Routers, I can’t imagine building a project without this extraordinary tool. Our Multi-Routers are used nearly every day and they’ve been trouble-free. I never worry about which one I’m using, because they all perform exactly the same way. These machines have proven so versatile that our shop motto could be, “If you haven’t figured out how to solve your problem, you haven’t tried the Multi-Router!”

Basic operation

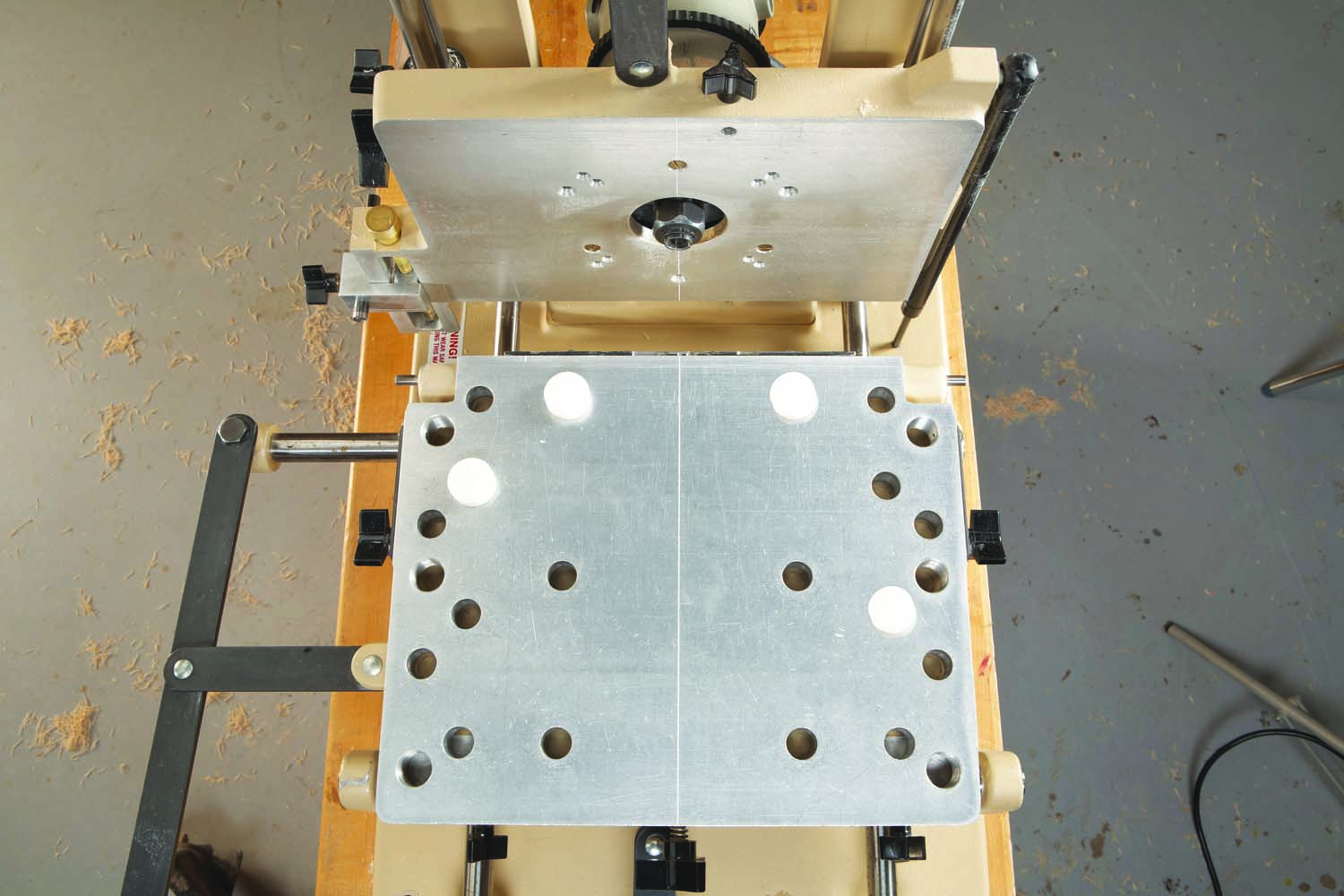

Like a mortising machine, the Multi-Router features 3-axis movement (Photo 1). The router mounts horizontally, behind the workpiece, on a vertical surface that moves up and down. The workpiece clamps on a horizontal table that moves in and out and from side to side. Levers and stops control the height, width and depth of the cut. Most operations require working two levers.

1. The Multi-Router features 3-axis lever-controlled movement. Cut mortises by moving the horizontal table in and out and from side to side. The vertical surface—on which the router is mounted—stays fixed.

To cut a mortise, you set the stops to establish its depth and length and then move the table in and from side to side. In most cases, the width of the mortise is determined by the bit’s diameter, so the height is fixed. An extra-wide mortise requires working all three levers or making two side-to-side passes, with a single height adjustment between passes.

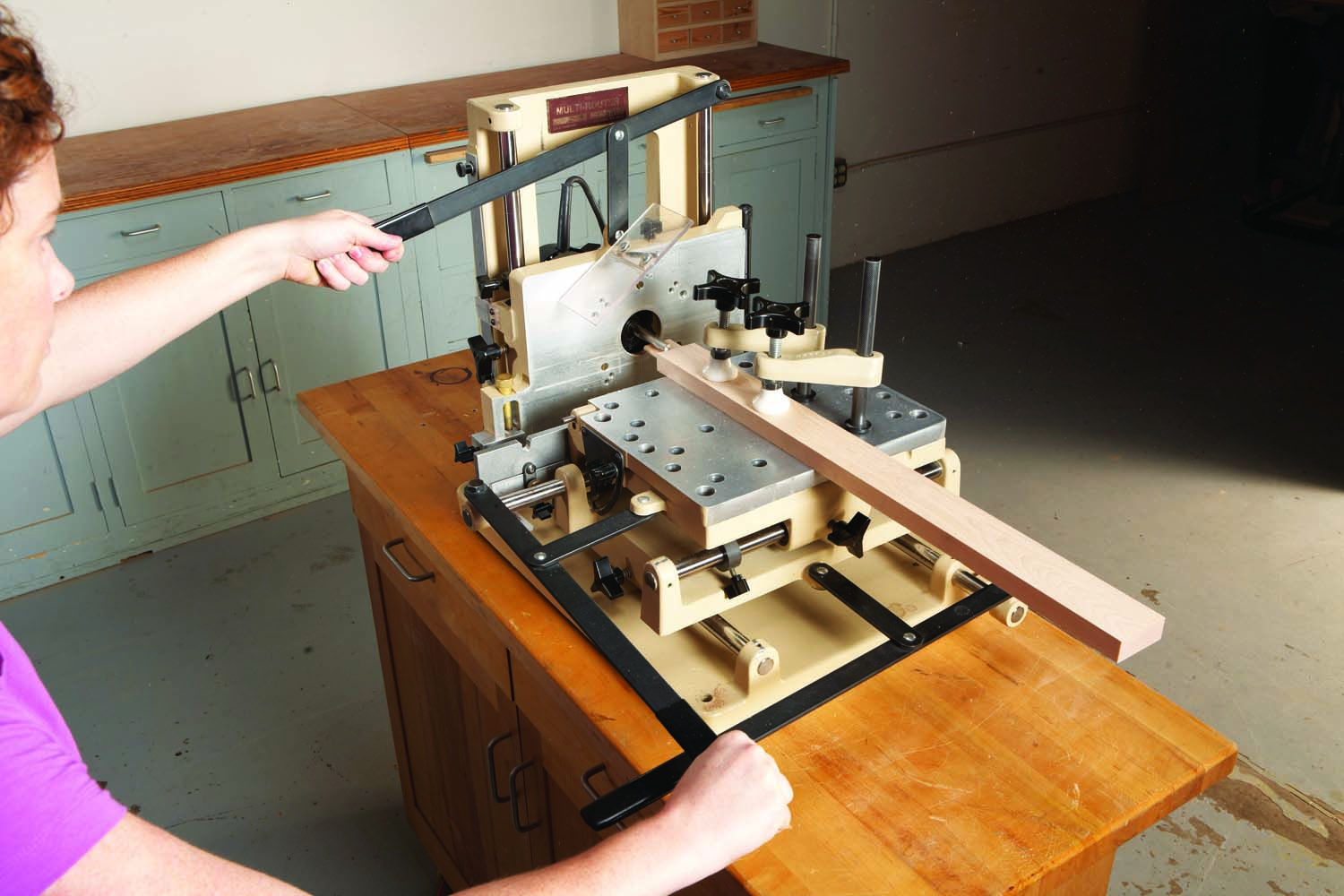

Similar operating methods are also used to cut rabbets, dados, grooves for blind splines and lap joints. Install a vertical panel-raising bit and you can even cut raised panels for cabinet doors. To cut a tenon, it’s best to use the Multi-Router’s template system (Photo 2).

2. Cut tenons using the Multi-Router’s template system. Move the vertical surface up and down and the horizontal table from side to side to guide the system’s stylus around the template.

Beyond the basics

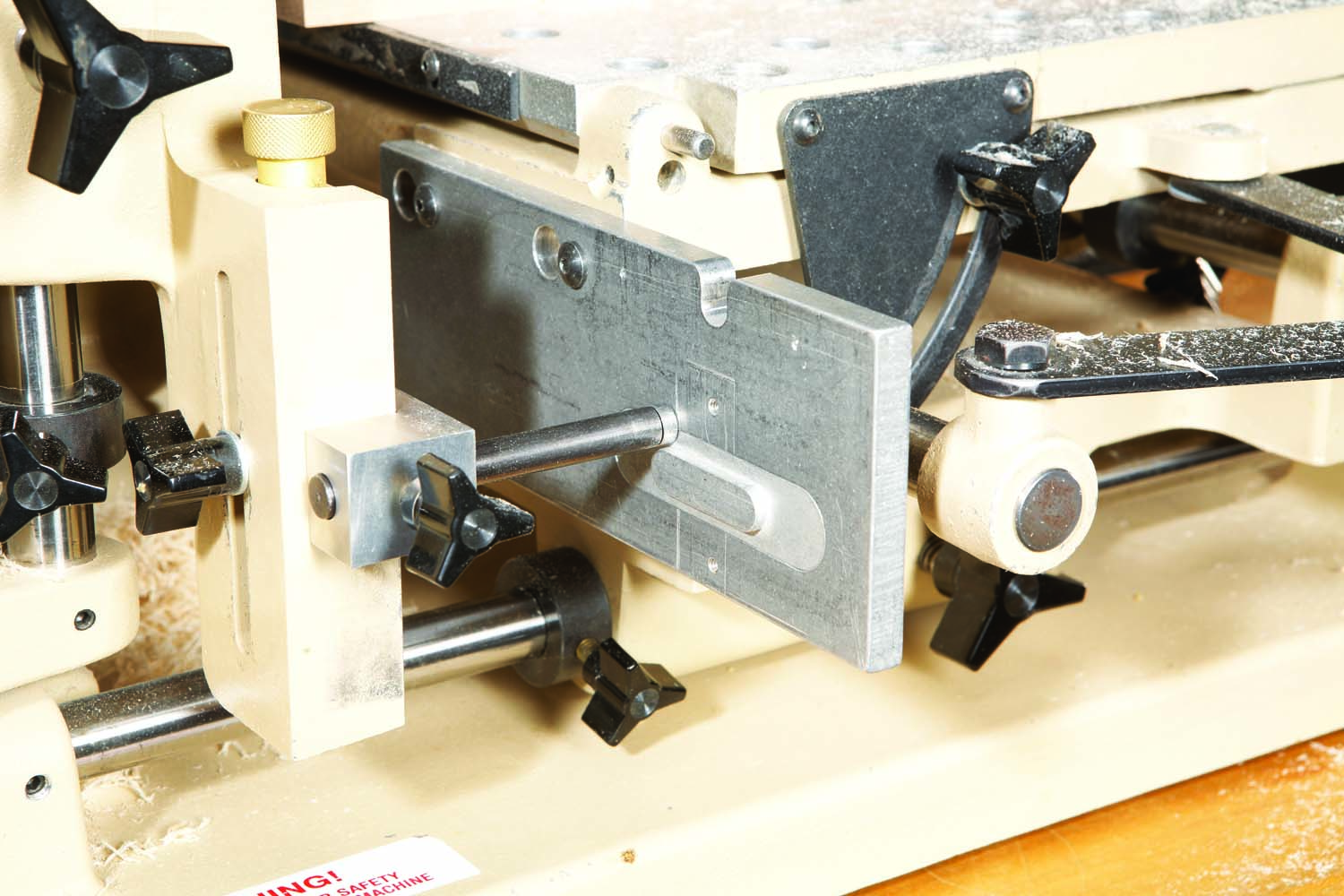

The Multi-Router’s template system produces joints accurately and consistently—it’s great for repetitive work and production runs. To work the system, you install the appropriate template and trace around it using the Multi-Router’s ball-bearing stylus (Photo 3).

3. Guide the stylus around the template after using the scale and adjustment screw to precisely dial in the starting position. The stylus travels smoothly thanks to its ball-bearing tip.

The one change to the Multi-Router mentioned earlier is that the stylus now has an adjustment screw that allows fine-tuning. Our shop has one old model and two newer models. Although this change is helpful, it hasn’t diminished our use of the old model.

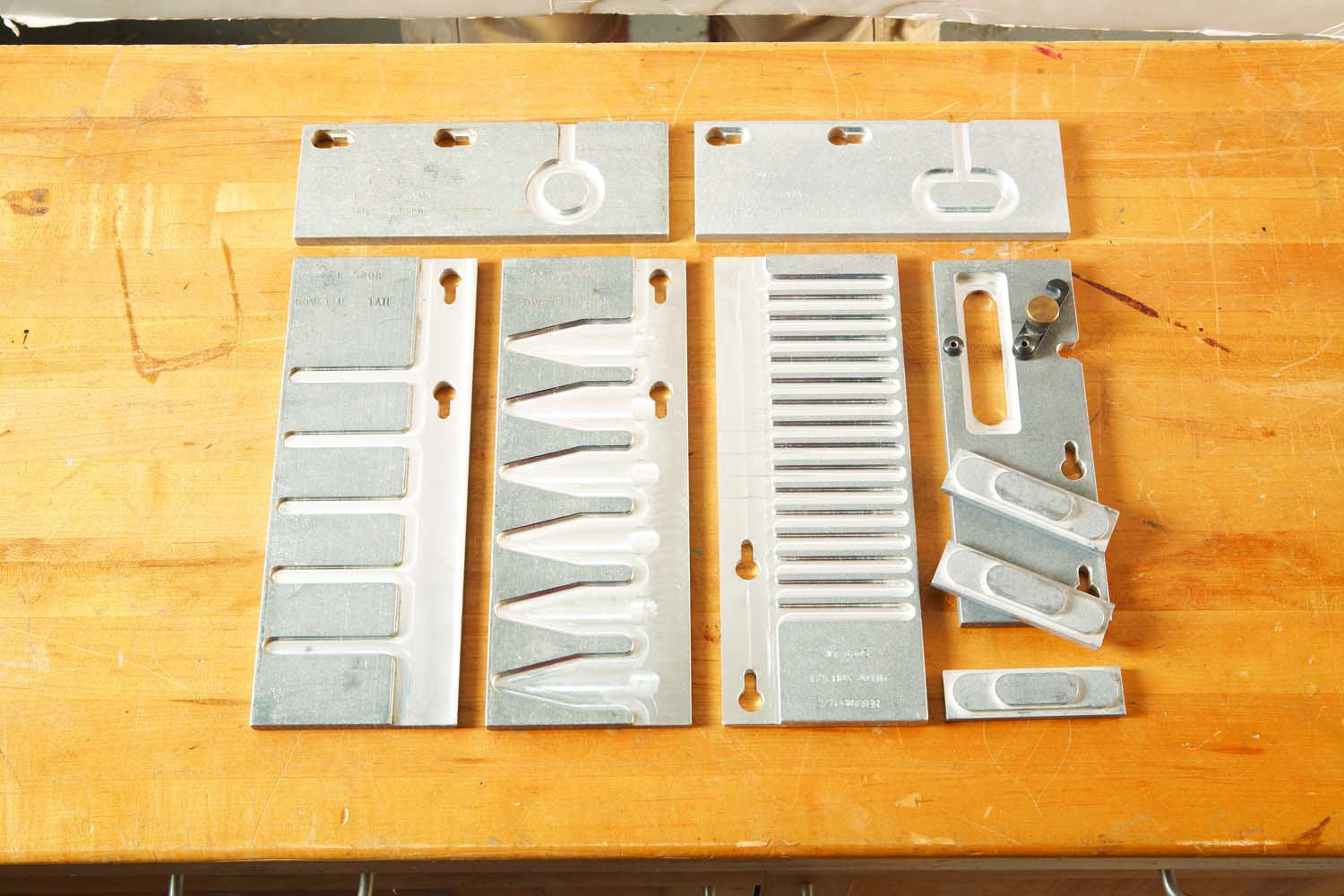

Machined aluminum templates are available for cutting box joints, through dovetails, mitered dovetails, traditional tenons and round tenons (Photo 4). Also available are variable-size tenon insert sets that allow adjusting the tenon size in .010 increments to fit mortises that aren’t accurately sized.

4. The extensive template system allows cutting dovetails, box joints and round and traditional tenons in a wide variety of sizes.

While it’s true that mortise sizes can vary slightly due to wood density or bit diameter, I’ve rarely round it necessary to use anything but the largest (standard-size) tenon insert. If a tenon fits too tightly, I just pare its cheeks with a shoulder plane.

Prices range from $42.95 for a standard tenon template to $68.95 for a dovetail set (pin and tail templates). Each set of variable-size tenon inserts costs $38.95; sets are available for 14 different tenon sizes. One way to control costs is to buy only sizes you’ll commonly use. Another option is to use loose-tenon joinery, which only requires routing mortises—then you won’t have to buy any tenon templates.

5. Holes and stop buttons position workpieces at common angles. Machined centerlines make it easy to center work on the bit—important when using the template system.

The Multi-Router’s horizontal table tilts from 0° to 45° and work can be positioned on it at almost any angle (Photo 5). That means you can cut angled and compound-angled mortises and tenons—a real bonus for chair makers. Clamp on shop-made jigs for even more variations (Photo 6).

6. Expand the Multi-Router’s versatility by installing shop-made jigs. Here a sloped jig acts as a side-tilting table to cut angled mortises for louvers on a shutter.

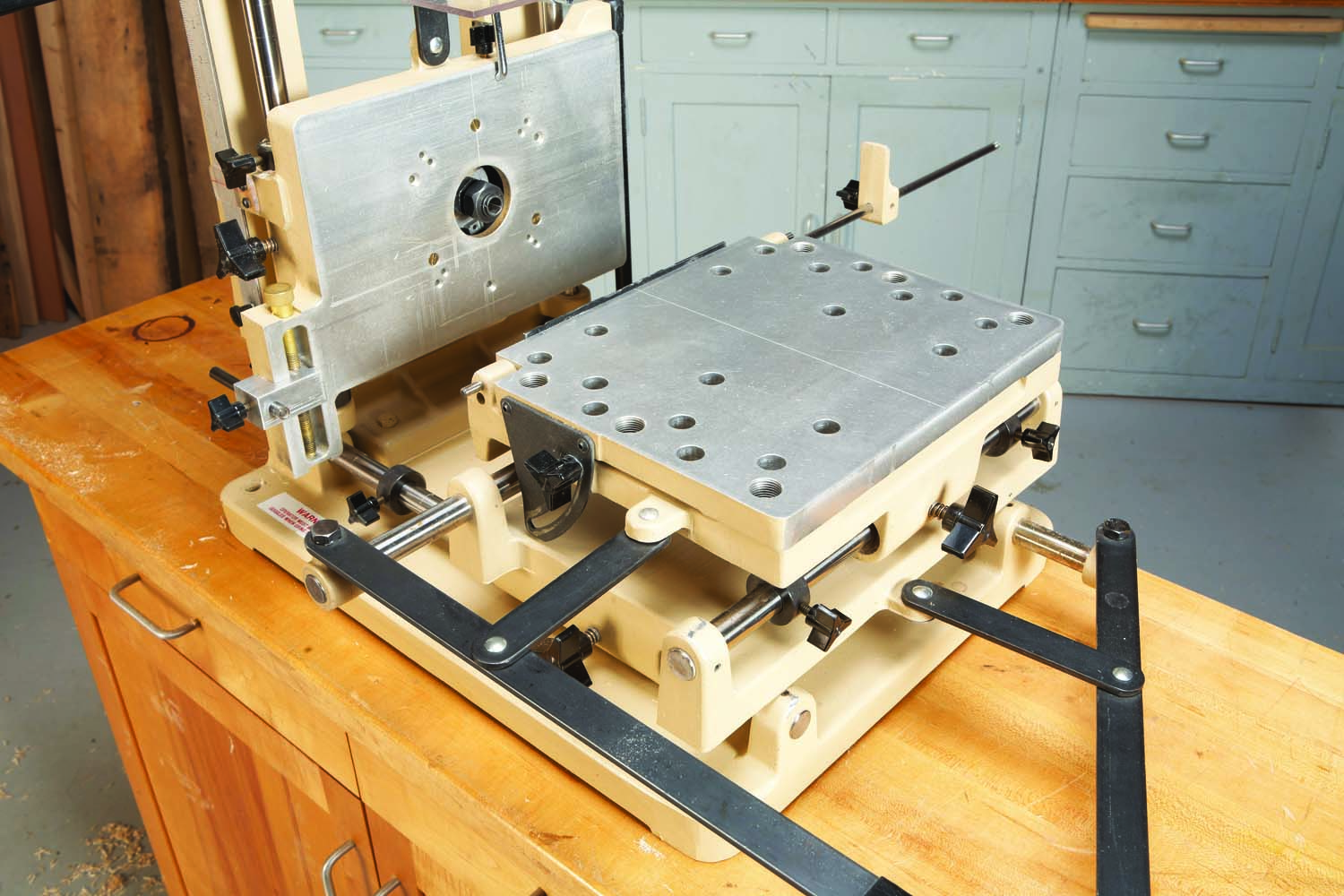

Nuts and bolts

The Multi-Router has been built in the USA in the same foundry and machine shop for its entire existence. Made using solid aluminum castings, it weighs 90 lbs. Thomson linear bearings, hardened steel rods and a gas-cylinder assist to offset the weight of the router insure smooth operation and long service life. The gas cylinder can be easily replaced, should that ever be necessary.

The Multi-Router comes almost completely assembled—install a couple parts and you’ll be good to go. There are no adjustments to be made and nothing to get out of alignment.

You supply the router (1-1/2 hp. minimum; 18 lbs. maximum) and carbide or high-speed steel (HSS) end mill bits. The vertical surface is pre-drilled and tapped for mounting several router makes and models—they’re listed online and in the manual. If your router isn’t on the list, you’ll have to drill and tap mounting holes.

The sliding stop collars and lock knobs that set the height, width and depth of cut tighten easily and hold securely, even though they take constant knocking as you operate the levers. To complete a cut, it’s best to keep the bit moving and make multiple shallow passes.

7. The horizontal table has sliding stop collars and lock knobs to set its side-to-side and in-and-out travel, an edge stop for positioning stock perpendicular to the bit, and an adjustable stop rod for repeatable cutting.

The 10″ x 12-1/4″ horizontal table features a steel edge stop and a stop rod (Photo 7). The edge stop can be lowered out of the way or removed. I often replace the steel edge stop with shop-made MDF edge stops, so I don’t have to worry about cutting into them.

The stop rod is useful for making repeatable cuts on pieces that extend beyond the sides of the table. A similar stop rod for pieces that extend beyond the front of the table would be equally useful, but isn’t available. The Multi-Router video shows a wooden one that’s easy to make.

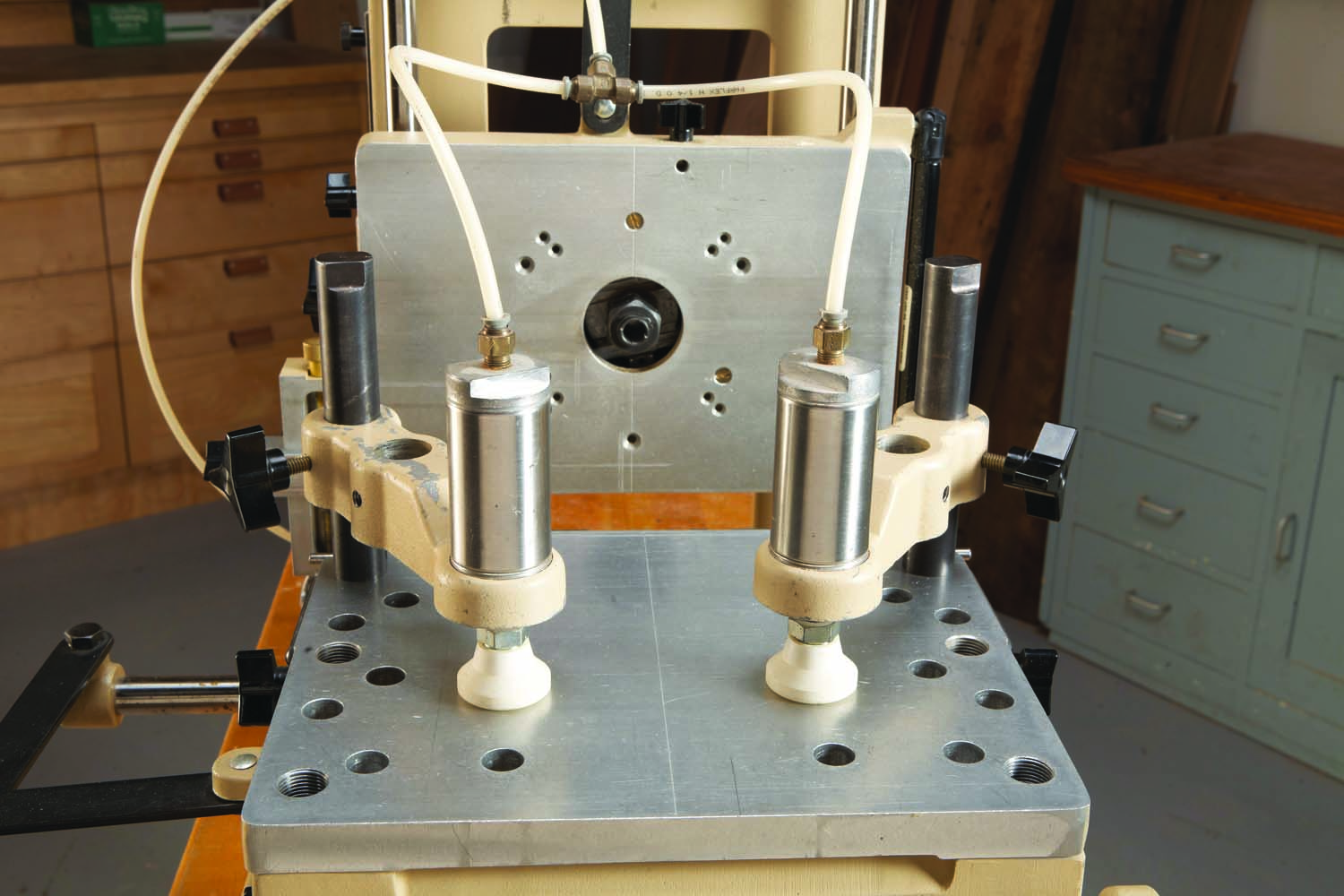

The Multi-Router comes with two heavy-duty manual clamps—two clamps are adequate for most operations. Additional clamps are available ($49.95 each), but when I need a third clamp, I can usually find a place for a regular F-style clamp without obstructing any of the moving parts. Pneumatic clamps are an upgrade (Photo 8; $399 per pair). These clamps have two mounting positions and a longer reach than the standard clamps. The table is tapped for them in six locations.

8. Pneumatic clamps, an extra-cost accessory, speed up production when making repetitive cuts. The supplied manual clamps hold work just as securely.

The height adjustment scale is very accurate (Photo 9). The optional Pro-Scale digital measuring system ($339) provides pinpoint accuracy, but as with pneumatic clamps, I haven’t found it to be necessary.

9. The height adjustment scale, primarily used to position the template stylus, is very accurate. I sometimes line up offset loose tenon mortises by just sighting the scale—and they’re always dead on!

The Multi-Router remains stable during use, so there’s little need to bolt it down. An open stand is available ($175.99), but I’d recommend a stand or bench with drawers or shelves to store all the accessories.

Unfortunately, there’s no easy way to collect dust, as the machine must be allowed to move freely. I’ve seen one creative solution that successfully captured most of the dust by combining a small overhead hood with a powerful collection system.

The bottom line

At $2695, the Multi-Router is a luxury most woodworkers can only dream about. But, it’s a dream machine that’s guaranteed to expand your woodworking horizons. It’s also built to last a lifetime: The Multi-Router shown here has been in use for over 18 years. Its stylus adjustment has been upgraded and the vertical table’s gas cylinder has been replaced once. That’s it. For small professional shops it’s a no-brainer: the Multi-Router will pay for itself many times over in time saved. For a woodworking enthusiast, a Multi-Router may mean being able to actually complete those weekend projects in a weekend.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.