We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

How I Started in Digital Woodworking

I had a long career as a designer. Long enough that I started out using traditional design tools, techniques and methods. So, when digital tools for designers first became available in the early 80’s, I jumped in. Even though the first design and publishing software programs were pretty basic, they helped me get real work done and soon became indispensable. I also really liked using them and didn’t miss the piles of X-Acto knife blades I went through or constantly cleaning out my clogged Rapidograph pens. Plus, when it comes to technology I’ve always been what is called, an “early adopter”. I often jump in early. Some days, that’s a good thing. Other days, not so much.

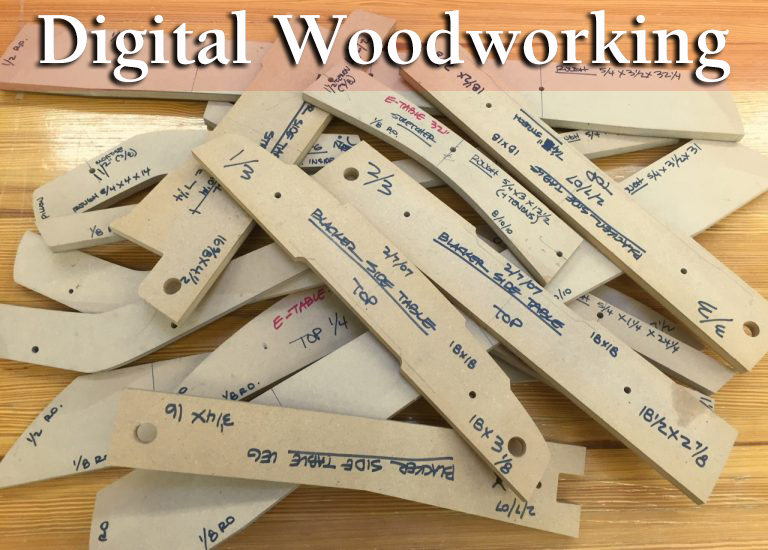

When I started woodworking as a hobby and later went professional it was only natural to continue to use computers and design software to create new furniture designs. So, when I would begin a project, I’d start by creating electronic drawings of the parts I planned to make. And, rather than print out the drawings on paper and tack them onto MDF or plywood to rough cut and shape in order to make a pattern, I thought that it made more sense to have a CNC cut out the patterns for me.

Using a CNC to Make Patterns

I went to a local sign maker who was one of the first in the Seattle area to use CNCs to cut out letters for signs. I’d used them in the past for some of the signs I designed for clients. Looking at how they did their work, I thought having them cut my patterns out of MDF would be easy. And, so it was. As a result, I started using CNCs and have made hundreds of my woodworking patterns since the late nineties with them.

This process has worked extremely well for me and it might be something for you to consider. Making patterns is also a terrific way to get started in digital woodworking by making use of a CNC or even a laser cutter service without actually having to own one. If you can create the required 2D CAD drawings of the parts you need and work around the vendor’s file and setup requirements. You could hand the files off to a local service, a large cabinet shop or service bureau with a CNC and they could make your patterns for you. You don’t even have to use CAD software. You could even create your drawings in other vector based programs like Adobe Illustrator.

Making patterns through a service is a great solution for getting many of the benefits of CNC accuracy without having to buy one. It’s also a great way to sample the world of digital woodworking. In future blog posts, I’ll get into more details on how to do this.

A CNC Service Can Do Even More

Over the years the process continued to grow and evolve as I increased my use of CNCs. Beyond patterns, I’ve used outside services to make parts for various jigs and fixtures and wooden parts, for particularly complex projects. I’ve found that great patterns make a real difference in the quality of the pieces you make. My work has dramatically improved in consistency and accuracy over time. It’s just like the excellent woodworking method of using story sticks for measurements rather than repeatedly pulling out your tape measure — a process prone to mistakes. Using good patterns means better quality parts and far less mistakes. I’m all in favor of that.

Obviously, I knew where this was heading. I would eventually have to get my own CNC. But, a couple of things held me back. First was the cost, space and power requirements needed for a machine. Next, I had other important decisions to consider before I was ready to commit to a machine of my own. More about that and other details in Part Two.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.