We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Carbon steel and cast iron are very susceptible to rust and, if not protected correctly against humidity and moisture, will catch a reddish layer of corrosion in no time.

The summer is here in earnest, and with it came the rising humidity. Humidity and ferrous-based metals such as carbon steel and cast iron don’t get along that well, and the result of the turbulent relationship between the two is rust.

I try to prevent rust infestation by covering my tools and machines’ exposed surfaces with oil, wax, or a special anti-rust paper. Still, unfortunately, some pernicious rust will always find a way and sneak through my lines of defense. It is better to deal with rust sooner than later as if left unattended, rust will set camp on your tools’ surfaces and spread out broader and deeper.

Spots of rust on my jointer’s cast iron outfeed table.

Iron oxidization or corrosion can wreak havoc on our tools and is incredibly frustrating when discovered on flat and true reference surfaces such as planers, table saws beds, and the soles and sides of our hand planes.

Thankfully, many products can help us remove freshly settled surface rust. Form chemical products such as Naval Jelly and POR-15 Rust Remover to the abrasive media such as Sandflex Hand Blocks, abrasive pads, and, let us not forget – the good old sandpaper.

Right to left: Sandpaper, Sandflex flexible abrasive pad, and Bronze wool.

I use the chemical compounds to remove deep rust but applying them takes time and could be messy. In contrast, the abrasive stuff is fast and effective – but it also sands away some of the steel (or the cast iron) around the corrosion. Therefore, I don’t like to use them unless I have to.

I recently discovered what I believe is the best, non-aggressive technique for mitigating light corrosion. This technique calls for the “soft power” of brass and bronze and is simple and easy to use. Brass or bronze are softer metals than cast iron and steel and will not abrade them, and yet these metals are harder than rust, so they could remove corrosion without damaging the unaffected areas.

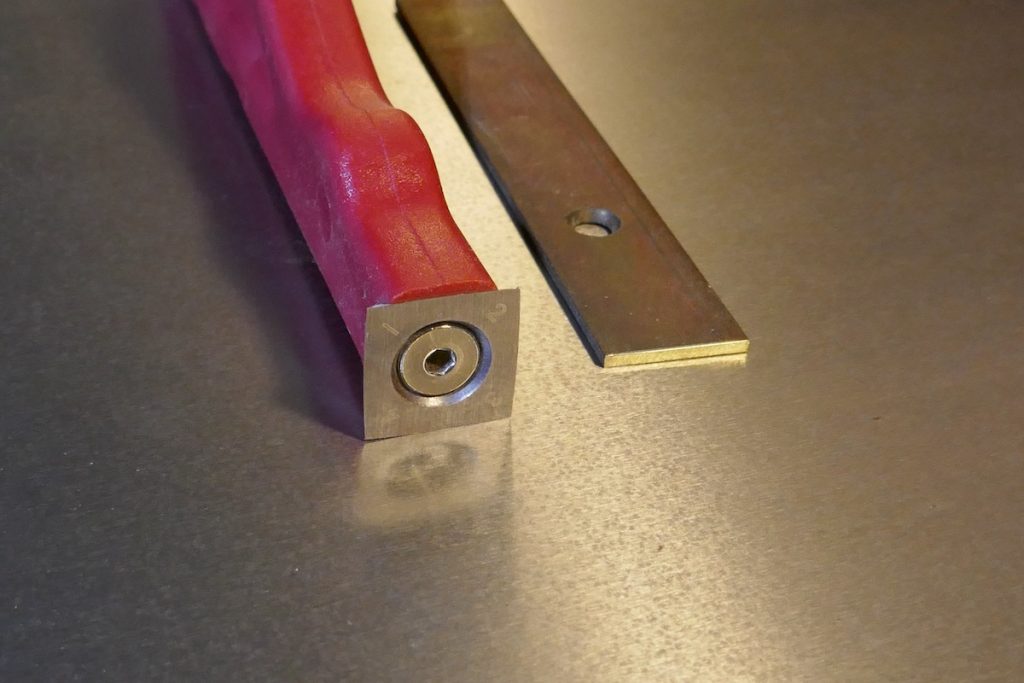

A carbide-insert scraper (left) is a very efficient and aggressive tool that, in addition to its traditional role of scraping dry glue spots, can remove stubborn rust blemishes too.

I came up with two main ways to incorporate brass and bronze: as a scraper and in the form of metal wool.

As A Scraper

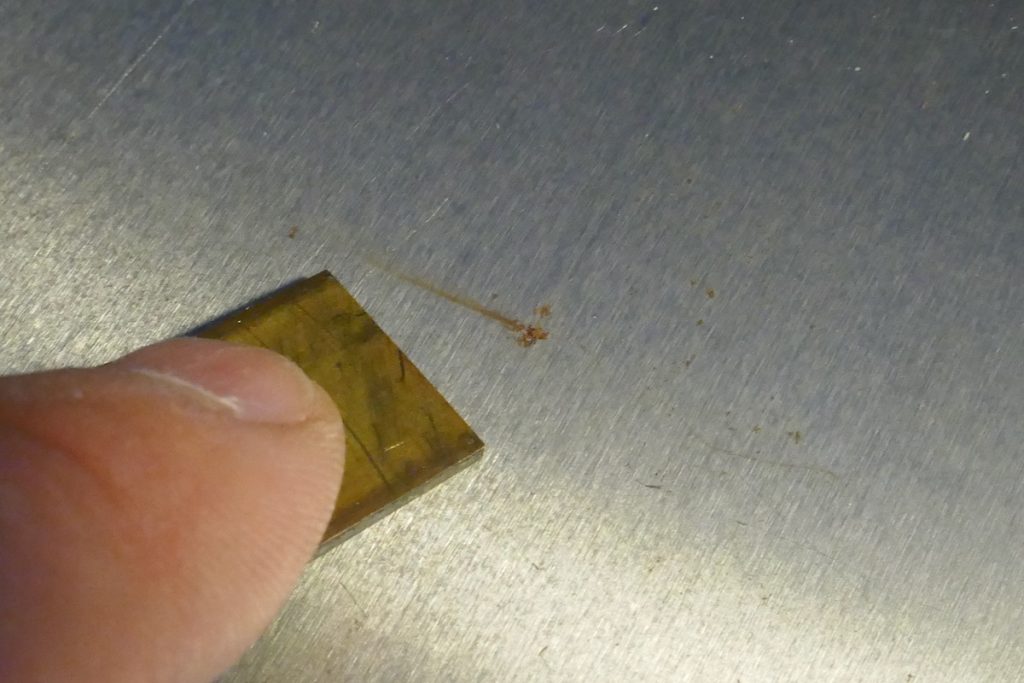

If you take an old brass hinge leaf and file its edge flat, you will form a sharp corner that can effectively scrape rust blemishes that developed over the surface. Moreover, filing the hinge’s edge will create a metal burr that, although not that strong, is excellent for this rust-removing job.

Make the scraper by holding a piece of brass (such as an old hinge leaf) in a vise and then filling its edge flat with a mill file.

A brass scraper is less effective than a carbide scrape and will be slower in removing the rust, but unlike the carbide scraper – it is incapable of accidentally scraping away the iron.

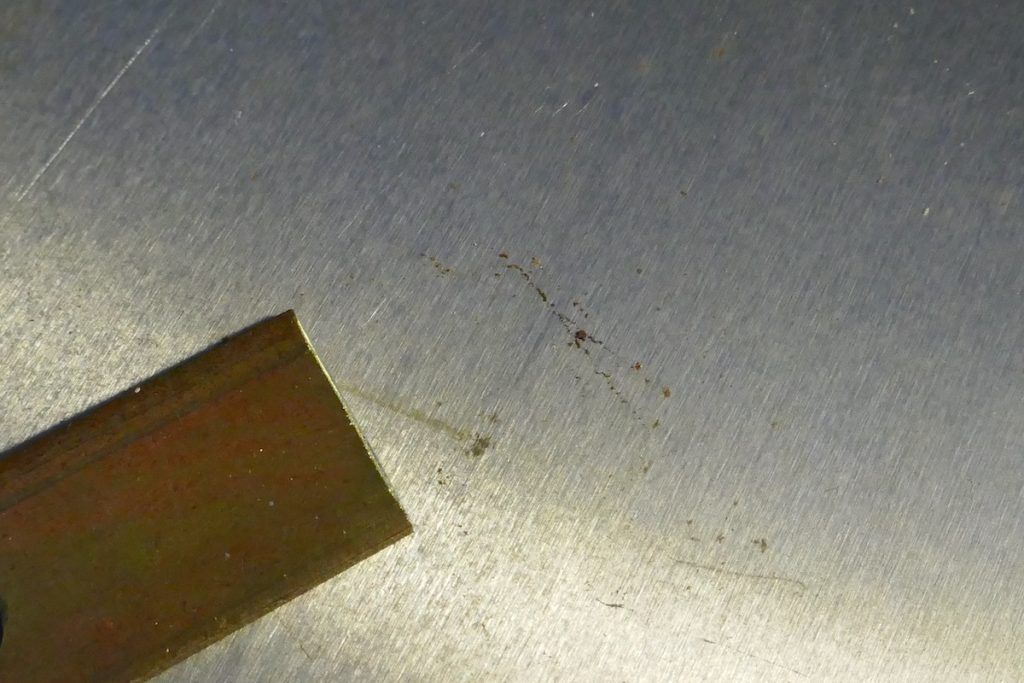

Scraping the outfeed table of my 8” Jointer with my new brass scraper.

As Wool

Bronze wool is a product I recently found out about. It can be very instrumental in tackling rust and will conform its shape to round, concave, and convex surfaces. I tried it on some of my tools, and the results are impressive.

Before

And after.

I purchased two bags of Medium and Fine bronze wool, but so far, I have only tried the Medium – which works great.

I discovered that using softer than iron metals such as brass and bronze allows me to scrape the rust without removing the unaffected surface near the corrosion.

Whether you use bronze wool or a piece of sharped-edges brass hinge, this rust removal technique is inexpensive and harmless to your tools, but it would not work so well on deep and entrenched rust. I would not try to implement it on every rusted surface – only on those we don’t want to alter by the aggressive minerals found in sandpaper and abrasive pads.

So practically, I will use it on plane’s soles, jointers and table saws beds and on rusted areas near the edges of sharp tools – to avoid dulling them. If I have to deal with rust on other surfaces, I will likely resort to the fasted and more aggressive sandpaper technique.

Since bronze is softer than carbon steel, using bronze steel wool to remove the rust blemishes near the ax’s edge will not inadvertently dull the edge.

At the end of the rust cleaning operation, wax your surfaces to protect them from future moisture.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.