We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

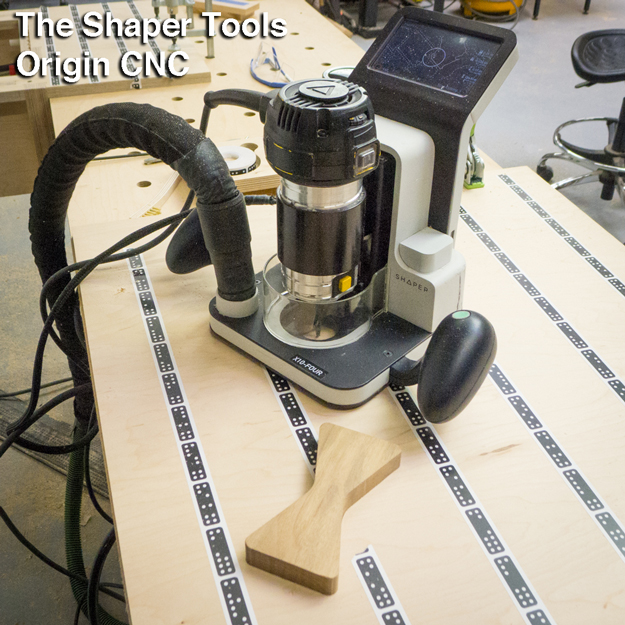

The Shaper Tools Origin: A Hand-held CNC Designed for Woodworkers

The Shaper Tools Origin. A CNC you can hold in your hand. That’s a perfectly mortised butterfly joint made by the Origin.

Last week I took a trip to California to check out the latest in digital woodworking tools: the Shaper Tools Origin. Essentially, the Origin is a very high-tech router. It uses a touch screen to guide you through a cut and CNC motion for accuracy. As you’re cutting, tiny corrections to your position are made along the way. After using one of the prototypes for a few hours, I can say that it works well. The Origin is also an easy tool to use, whether you are new to digital woodworking or more experienced. And, it’s attractively priced. That’s a lot of very good news. The bad news is that the Origin is still under development and won’t be available until fall 2017.

Joe Hebenstreit, CEO of Shaper Tools demonstrates a prototype of the Origin

The Tour

When visiting the home of Shaper Tools, you can tell right away that this is unlike most woodworking tool development projects. For one thing, the company’s location is deep in the heart of one of San Francisco’s famous technology communities. For another, the developers are the kind of sharp and talented young people that you’d expect to see working at Google or Amazon or Uber. But, being different can be a good thing. It’s an outside perspective that often leads to interesting new solutions to traditional problems. Look at Tesla, and how it’s a different and successful challenge to the auto industry, for example. Different thinking can bring different results. In this case, Shaper Tools’ goal is to bring CNC accuracy and simplicity to a handheld woodworking tool. The Shaper Tools Origin is the result.

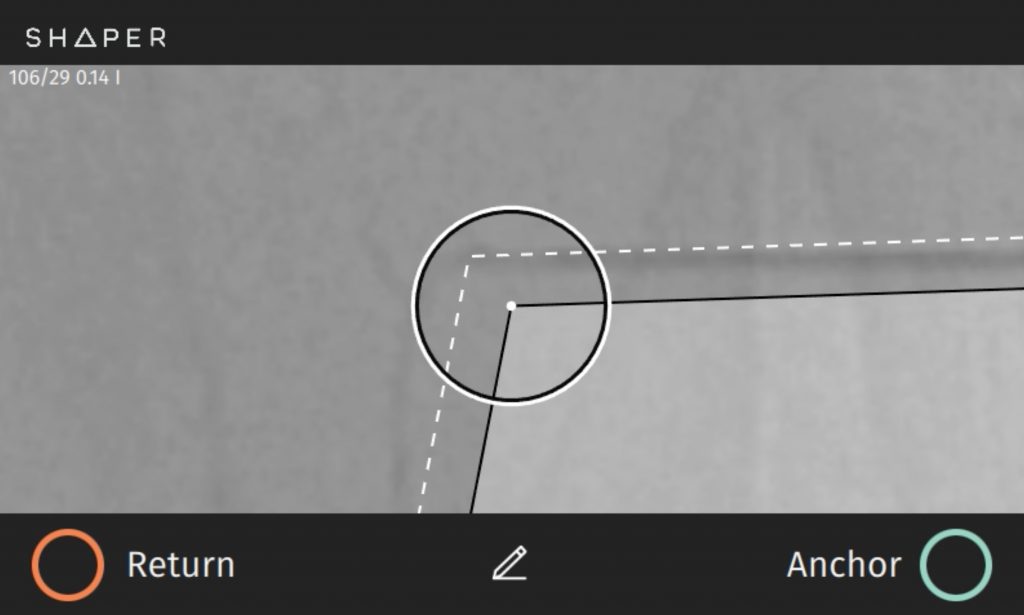

To make a cut you just follow your drawing on the screen. Keep your cut inside the circle and the tool does the rest.

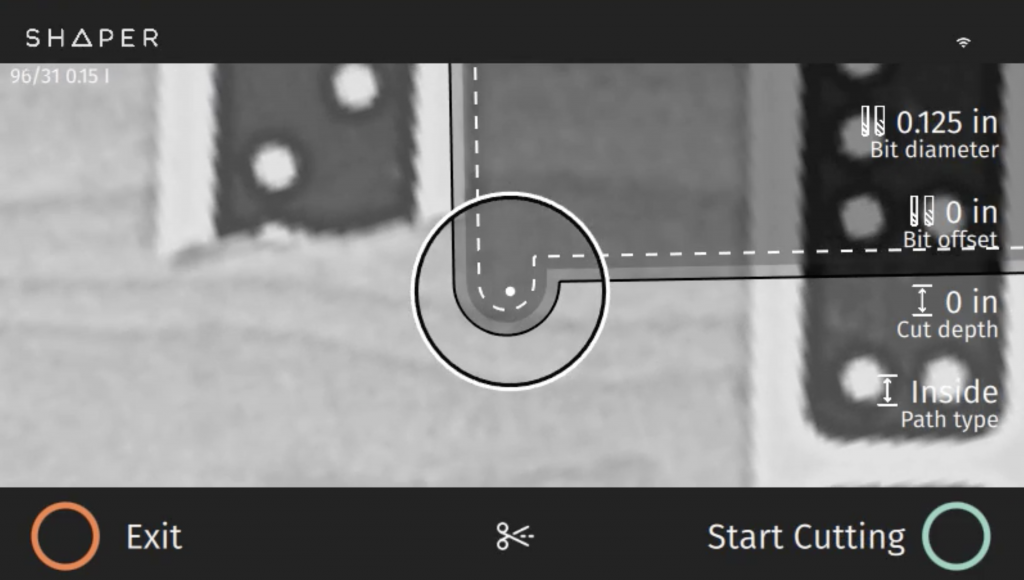

You can even cut inside the line. In this case an opening for a plywood CNC joint.

How does the Shaper Tools Origin work?

As with any handheld router, you place the Origin on top of the material that you’re cutting. But, unlike conventional routers, to cut accurately you don’t have to contain your movement with a straight edge, guide or a pattern. On the Origin, you follow along with the lines of the drawing shown on the small screen on top of the tool as you move. The good news is that you don’t have to be perfect as you’re tracing the drawing. You just need to come fairly close. The Origin does the rest.

As you’re making the cut, the Origin is adjusting to match the drawing nearly perfectly by correcting your movements. It does by using small stepper motors to make minute tweaks to the router’s position. It’s putting the bit precisely where it needs to be so that the results come out exactly like your drawing.

Here’s an example. Imagine trying to use a hand held router to freehand cut a perfect 8” circle out of a piece of plywood. Even on your best day, you won’t come close. With the Origin, it’s simple. Just follow the drawing of the circle on the screen. The Origin makes it perfect for you. You can cut a circle, a shape, or any design you can come up with for results within a 1/100” accuracy. And, accuracy is what digital woodworking is all about. In the case of the Shaper Tools Origin, you’re putting CNC accuracy into a tool that you hold in your hand.

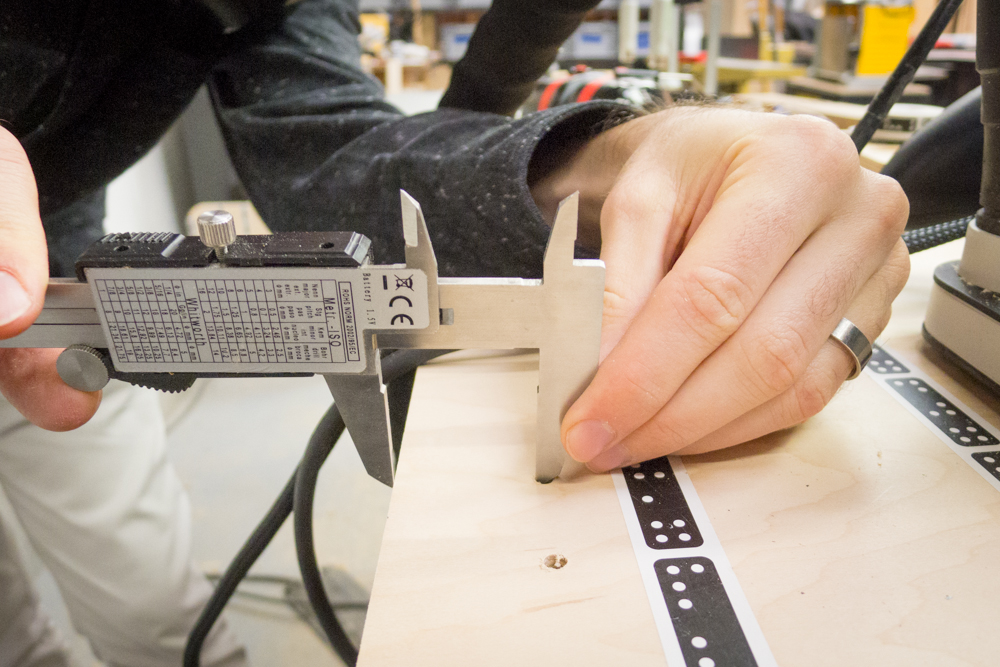

The Origin gets its orientation from patterns of dots on a tape that you place every few inches on the material that you’re cutting from.

Precision cutting and spacing of shelf pin holes can be done with the Origin.

A Portable Tool Needs to Know its Location

In order to achieve accurate results with any digital tool, be it a CNC, 3D printer or laser cutter, the tool needs to know two things: a defined workspace and its location within it. On fixed tools like a CNC, the workspace is clearly known. A 24” x 48” CNC, for example, works inside an obvious boundary and knows it’s location within it. But, on a hand-held tool like the Origin where you move it to different locations and use different sizes of materials, defining a workspace is a challenge.

To solve this, Shaper Tools developed a special tape with patterns made up of dots. Much like fingerprints are unique, the different patterns on the tape are unique. You simply lay out the tape every few inches or so on the material you’re cutting. The Origin uses a small camera that scans the workspace and references the dots to accurately judge the tool’s location. As you’re following the drawing on the screen, it’s using these patterns to keep track of where it is. Along the way, it’s fine tuning the router’s position so that it’s cutting where it’s supposed to. If you get too far off line, the router’s spindle is quickly raised up to keep it from cutting outside the line.

What About Those Drawings?

Digital woodworking always requires drawings. The Origin works from digital drawings created in CAD or other vector based drawing software like Adobe Illustrator. Getting them into the Origin is easy. It communicates via Wifi. Or, you can just transfer files from your computer via a handy flash drive.

But it’s not just the tool that’s different. Shaper Tools is also creating an interesting solution for help you get the drawings that you need. Besides being able to use your own designs, Shaper is developing ready-made designs that they’ll make available through a cloud-based solution they’re building called, ShaperHub. There, the company and outside contributors will be offering ready-to-go CAD drawings and complete projects for users to share, purchase and use. This will work something like Apple’s App Store. Find a design you like, download it into the Origin and build it.

Iteration is a key to solid engineering and design development. Shown are several different Origin prototypes

The Shaper Tools Origin in near final form.

If the capabilities of the Shaper Tools Origin have piqued your interest then you likely have two questions. When will it become available and how much will it cost? The Origin is slated for release in September 2017 and the cost is pegged at $2099. However, they are offering a limited pre-sale price of $1499 if you’d like to order one early.

There’s more to come about the Shaper Tools Origin. In a future post, I’ll get into more detail on what you can do with it, how it compares to conventional CNCs and where the tool fits within the digital woodworking world and inside an average woodworker’s shop.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

It is good to see at least one woodworking magazine embrace new technology.