We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Every woodworker eventually faces a universal challenge: needing to glue up a long panel, like a tabletop or a shelf, only to find that your longest clamp is still inches too short to span the full distance. This was my exact dilemma recently when building a long, utilitarian shelf for a drywall ledge in the basement. I decided to assemble the shelf from two shorter boards—a practical solution that saves precious longer stock for more visible projects.

Every woodworker eventually faces a universal challenge: needing to glue up a long panel, like a tabletop or a shelf, only to find that your longest clamp is still inches too short to span the full distance. This was my exact dilemma recently when building a long, utilitarian shelf for a drywall ledge in the basement. I decided to assemble the shelf from two shorter boards—a practical solution that saves precious longer stock for more visible projects.

Any time you join two short pieces end-to-end, the joint needs structural reinforcement to be reliable. By securing the end-grain-to-end-grain joint with internal fasteners like dowel rods, biscuits, splines, or a floating tenon, the joint can become quite strong. (If the longboard requires additional stiffening after the glue-up, you can always add an apron.)

The real question, however, is not how to reinforce the joint, but how to apply sufficient clamping pressure to compress the two boards together when your clamps are too short.

I utilized two highly effective, low-tech solutions:

Method 1: The Extended Clamp System (Movable Jaw Link)

The simplest way to bridge a gap is to physically link two shorter bar or pipe clamps together to act as one long compression tool.

The Technique:

- Place the stationary (fixed) jaw of the first clamp against the end of one short board (Board A). This jaw will serve as the fixed anchor point.

- Bring the movable, tail-end jaw of the first clamp close to the center joint.

- The stationary (fixed) jaw of the second clamp is now used as the compression anchor. Place the stationary jaw of the second clamp against the movable jaw of the first clamp, linking them end-to-end.

- The screw-side jaw (the clamping head) of the second clamp is then placed against the end of the second board (Board B).

- By turning the screw on the second clamp, the entire combined assembly tightens. The second clamp pushes against the first, which pushes against Board A, compressing both boards together.

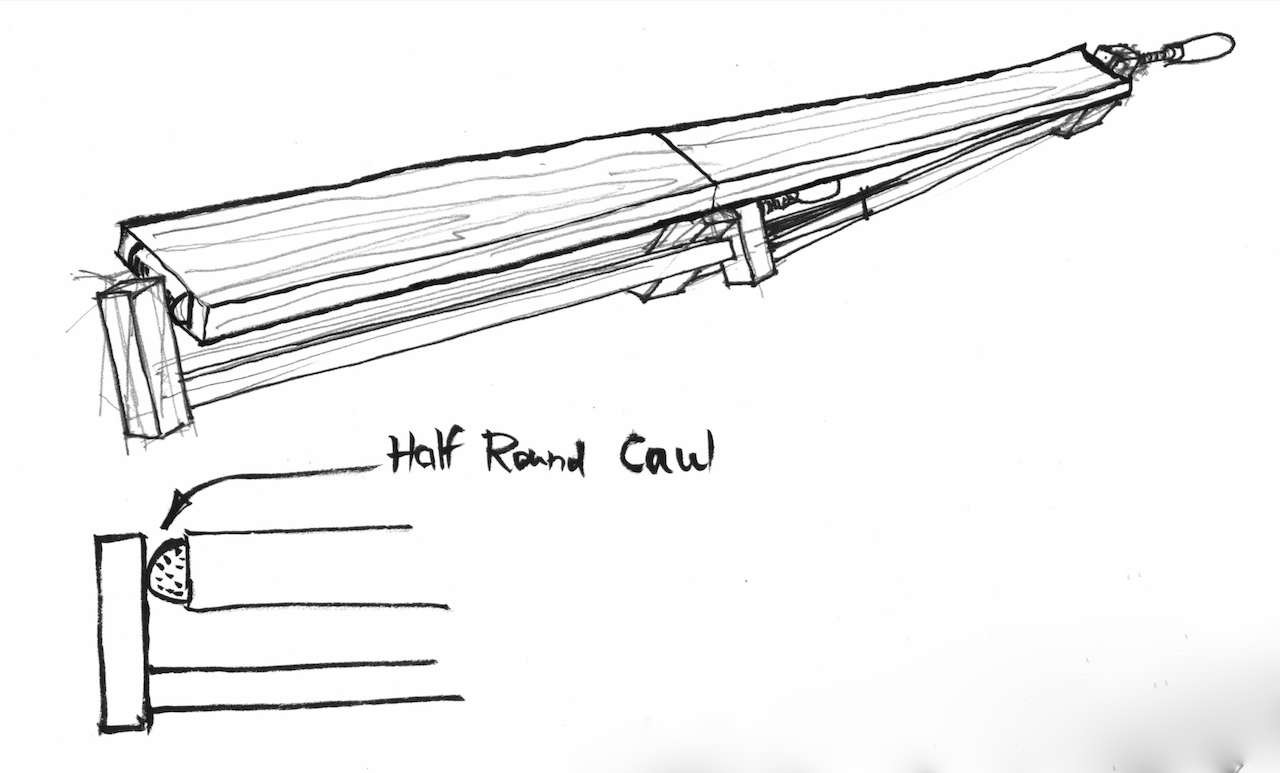

The Caveat: Preventing Bowing. While this technique works mechanically, the weight and inherent awkwardness of the extended, combined clamp assembly can cause the boards to flex or bow, especially at the joint line, resulting in an uneven glue-up.

To prevent this distortion, you must provide strong cauls (flat pieces of scrap wood) along the length of the boards. Clamping these cauls tightly across the joint will hold the boards flat and prevent them from bowing. Alternatively, you can use a thin piece of wood connected with masking tape across the end-grain of the joint boards to distribute the clamping force more evenly.

Method 2: The Cauls Compression Method

This technique is more controlled and completely bypasses the need for the clamps to span the entire length. Instead, you use short cauls and secondary fixation methods to create an artificial clamping point close to the joint.

The Technique:

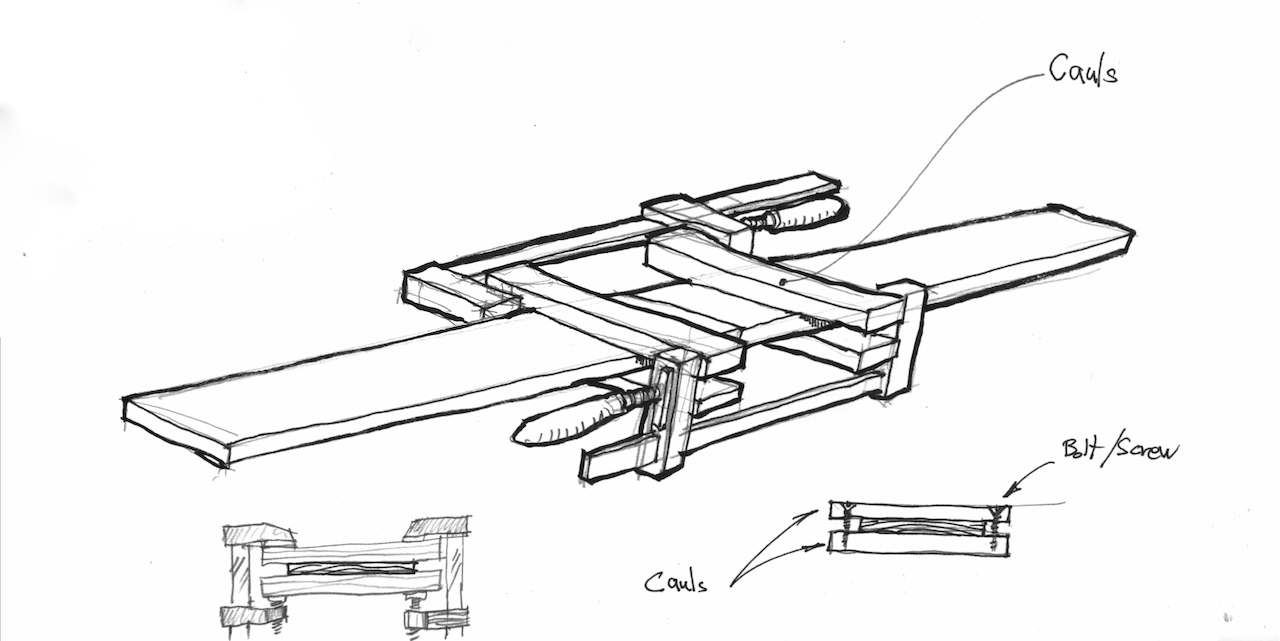

- Preparation: Cut four short cauls (two for the top, two for the bottom).

- Placement: Place two cauls on one side of the joint (top and bottom) and two cauls on the other side of the joint (top and bottom). The cauls should slightly overlap the joint line.

- Locking the Drive (Vertical Clamping): You need to securely lock the cauls onto the boards to create a solid, stable anchor point. This can be done in two effective ways:

- Option A (Secondary Clamps): Compress the cauls together using secondary clamps (short ones are fine) placed vertically across the width (thickness) of the board.

- Option B (Hardware): Alternatively, use carriage bolts or screws that span the width of the board and pass through the cauls, tightening them to compress the cauls against the boards. This is often preferred as it frees up clamps and provides a more rigid, non-obtrusive anchor.

- Creating the Drive: This locked pressure creates a solid anchor point at the ends of the boards.

- Final Compression: You can now use your main clamps to push the two sets of locked cauls together, which in turn compresses the two boards tightly at the joint line. This method offers a highly controlled way to apply massive force exactly where it’s needed without worrying about a long clamp assembly sagging or pulling the joint out of alignment.

There are other clever ways to achieve a long glue-up, but these two methods offer the most practical and reliable solutions when you’re short on clamp length.