We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

A few simple tools and supplies, used regularly, will help keep your lathe functioning smoothly so you can concentrate on your turning. A file, rubber-bonded abrasive blocks such as Klingspor’s Sandflex hand blocks (or sandpaper), paste wax, machine oil and some clean cloths are all you will usually need.

Regular attention to a few simple procedures will keep you turning smoothly.

A lathe, like any other piece of woodworking equipment, is exposed to wood shavings, dust and other substances as well as general wear and tear. The bed, toolrest base and toolrest especially require regular attention for easy functioning. I can’t count how many times I’ve watched people huffing and puffing, trying to slide a toolrest around on a lathe bed that is as rough as sandpaper (or as sticky as flypaper). Not to mention the number of times I’ve had to face such a lathe myself while doing demonstrations.

A poorly maintained lathe is no fun to use and can easily frustrate your efforts to achieve those lovely, clean cuts and smooth curves you so want your work to have.

Some very simple procedures, regularly done, will prevent such frustrations. How often you need to do these things will vary according to how much you turn and what kinds of things you are doing with the lathe. I generally clean and wax the bed, toolrest base and tailstock base; and I file, polish and wax the toolrest itself about once a week when I’m using that lathe every day.

If you are turning a lot of green wood, however, you should probably at least clean, polish and wax the bed each time you are done turning for the day. (A gunked-up bed is bad enough, but a rusty one is unforgivable.) If you turn only small items of dry wood and don’t finish them on the lathe, you may need to do this only occasionally.

Less often, you will (or may) need to clean out electrical switches, adjust the alignment of the head and tailstock, make sure there is even pressure on all four feet of the machine, balance the handwheel and so on.

You should always read and make sure you understand any information or directions that came with your particular machine. There may be specific maintenance recommended for that machine that isn’t mentioned here.

And last but definitely not least, don’t forget to perform regular maintenance on your face shield. This essential tool isn’t something you can buy and then use forever without further attention. The shield will become scratched, spotted and smudged over time.

While regular cleaning will certainly add longevity to your face shield, you’ll need to replace it occasionally, so you can actually see all those wonderful things you are making as you turn them.

1. I use this white board to provide a clean visual background while I am working, as well as to prevent any item I don’t catch (as I part it off) from dropping behind the lathe where it would be harder to retrieve. The board is laminate glued to hardboard. Finish materials, paint and sometimes moisture from wet wood are all flung onto the board during turning, so it needs to be cleaned regularly. After cleaning, I apply a coat or two of paste wax to keep things from sticking to it.

2. The toolrest is subject to considerable abuse, and regularly develops scratches, dings and grooves. These irregularities interfere with the movement of the tool as it slides along the rest, and this will make turning accurately and cleanly more difficult.

3. Place the toolrest in a convenient position and lock everything down. Cover the bed to protect it from metal shavings, and file the top of the toolrest to remove the irregularities. Run the file along the front edge a couple of times too, or it will become quite sharp over time. I use rubber-bonded abrasive blocks to further smooth the rest; you can also use sandpaper. Then coat the toolrest with paste wax, allow it to dry and buff with a clean cloth.

4. The bed of the lathe quickly becomes scratched and covered with sap residue and finish materials, making it more difficult to move the toolrest.

5. Remove the tailstock and toolrest base. Polish the bed with rubber-bonded abrasive blocks or sandpaper (#180 grit is good, unless the bed is badly scratched or dinged) until it is clean and smooth.

6. Apply a thin coat of paste wax, allow it to dry then buff it smooth with a clean cloth. Two or three coats won’t hurt, particularly near the headstock, where buildup tends to be heavy.

7. Clean out the Morse taper whenever you are going to insert a drive center (or live center, in the case of the tailstock). If you don’t have a taper cleaner tool like this, you should at the very least blow any dust or other particles out of the opening.

8. If your lathe has a handwheel on the outboard side of the headstock, be sure it is running true; an unbalanced handwheel causes vibration while you are turning. This one was slightly off; a sliver of paper in the right location between the wheel and the flat it tightens against solved the problem.

9. Run the quill feed on the tailstock all the way out, clean off any debris and place a drop of oil on the spindle before retracting it.

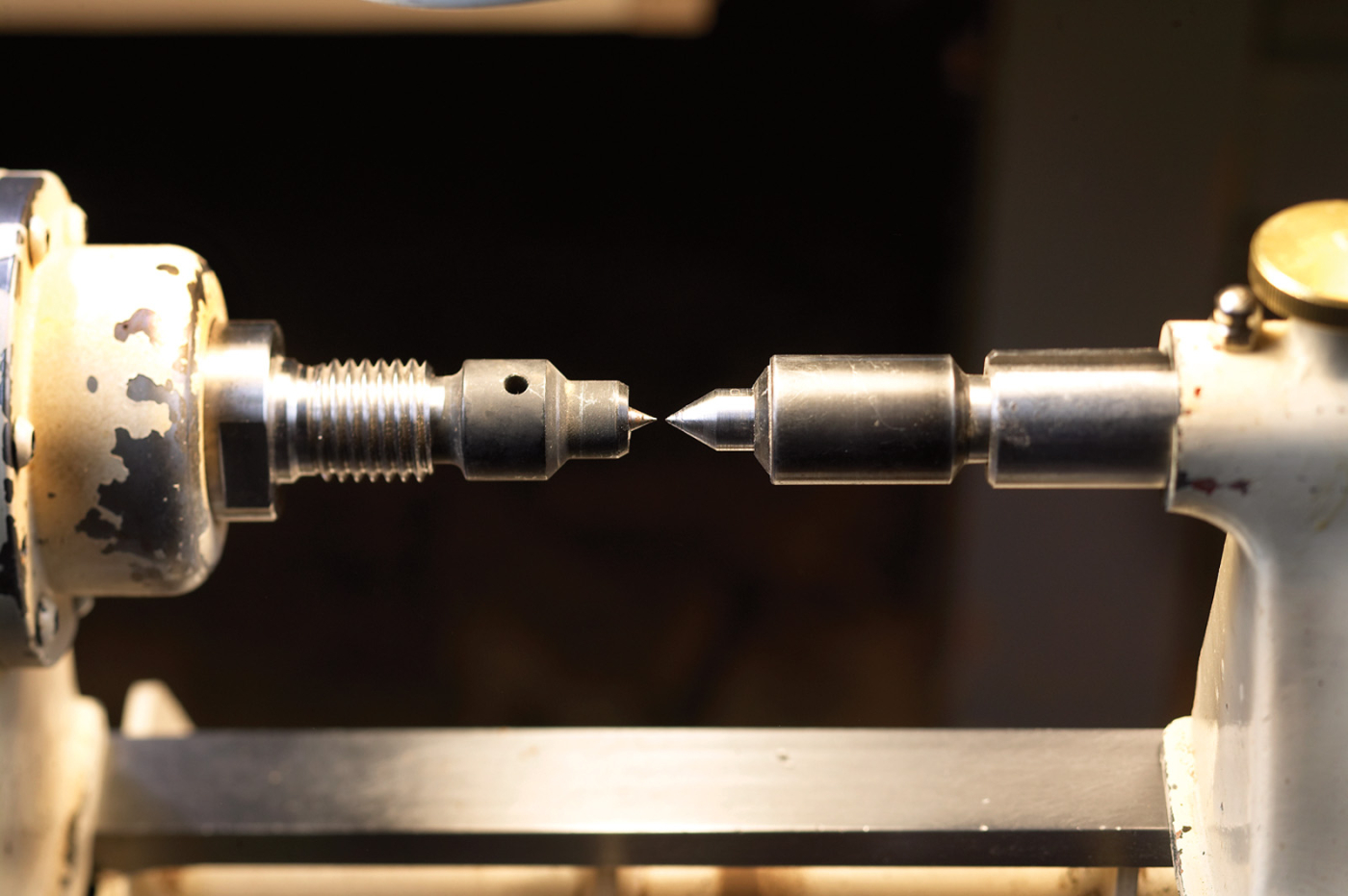

10. Check to make sure the centers on the headstock and tailstock align properly. If they don’t, follow the appropriate procedure for your particular machine to adjust them.

11. Keep belts properly tensioned. If they are too loose, the belts will slip too easily during turning; if they are too tight, the belts will wear out faster. Check for any unusual wear or fraying on the belts; if you see any, determine the cause and correct it before further damage occurs.

12. Some lathes provide a means for leveling. While it isn’t necessary to have the bed of the lathe level, all four feet must have the same pressure on the floor to prevent wobbling. I do keep the bed of my large lathe level; it’s handy sometimes to have a clean, flat surface in the shop that I know is level.

13. The bottom of the toolrest and the tailstock pick up debris and scratches, although not as quickly as the bed. Sand or polish, then wax as with the bed and toolrest.

14. This is the remote switch on my small lathe. It sits under the handwheel on the outboard side of the headstock, a location which is very convenient for me while turning, but which exposes it to a lot of dust. I find I need to clean it out occasionally. Don’t forget to unplug the machine before opening the switch.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.