We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

I’ve worked in a 2,000 square-foot professional shop and I now work in a one-car garage shop, and the one thing that’s universal for all shops is that you’ve got to be able to find stuff. Whether it’s the marking gauge that was on the bench just yesterday, or that ogee router bit that is in either the router or the drawer, disorganization is a big hang-up. You can waste a lot of valuable shop time if you’re running around looking for tools.

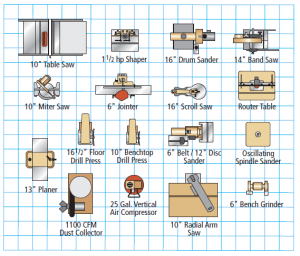

So organizing a shop (and putting things back where they belong) is a great habit to develop. That starts with how you have your shop laid out, and what storage you can make available. I’ve uploaded a free PDF of an article from Popular Woodworking that will give you some insight into that initial set up, or can help you rearrange if that’s necessary.

Once you’ve got the plan set, it’s time to build some storage items – the fun part!

- I highly recommend a clamp rack (a rolling clamp rack and one on the wall are both good ideas).

- Next are a couple dual-purpose items. If you don’t have a router table, build one that has storage underneath for router bits, wrenches and more. Using the same thought process, drill presses usually waste a lot of space underneath, so build in a cabinet for more storage (perfect for drill bits).

- Do you use saw horses in your shop? How about replacing them with a couple rolling drawer bases that offer stability and storage! And if you’re really thinking, you can make it so the plank on top is height adjustable.

Those are just a few ideas to get you started organizing a shop, but you can find books, videos and many articles on shop projects to help optimize your space and time in our online store. Our big sale starts this weekend.

–David Thiel

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

I have reduced my shop floor space needs by buying and using a Shopsmith Mark V and a Shopsmith 510. I have all the accessories for them mounted on a shelf out of the way, and use hand tools unless I need power equipment. I appreciate the accreacete setup ability of the Shopsmith, being able to set it up to metal working accuracy if wanted. Also each machine only takes the floor space of a bicycle, so even a table saw would be two big. I have been using a Shopsmith since purchasing my original Mark V in 1979, and have used it in at least 5 different home shops as I have moved around the USA. The largest item in my shop is an 8-foot long, 3-foot wide by 8-inch thick workbench. It is huge, heavy, and wonderful. Since Norm Abram every one wants a huge shop with big equipment able to do every thing and costing more than most of us will ever be able to afford in space or equipment. He has hurt woodworking a much as Roy Underhill has helped it.

Thanks for this. The article was great, and the layouts that were presented were very helpful in debugging my new shop, which has plenty of space, but just hasn’t been comfortable. I think I’ve now got it right with work- flow alignment of the planer, jointer and table saw.

Thanks much,

Rick