We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Two-Part Bookcase

Here's a big bookcase that you can build in a small shop.

By Tom Caspar

|

Building a tall bookcase can stretch the limits of a small Biscuits join the shelves and sides. It’s a snap to put together |

You may also like… |

|

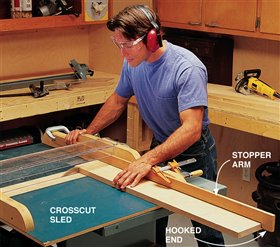

Trim long and wide boards on your tablesaw with a |

Click any image to view a larger version. |

|

Rip the stepped board (C) on the bandsaw. A simple |

|

Glue the upper case sides from 1" thick rough |

|

Plane the glued-up case sides until there are no |

|

Cut biscuit slots in the ends of the shelves. You can’t |

|

Cut more biscuit slots in the case side. Stand the plate |

|

Glue the backboard onto the case side. Make sure it’s |

|

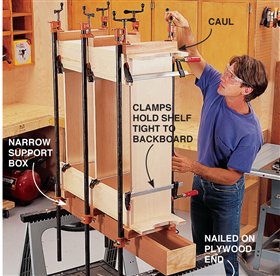

Mark the position of the shelves on the backboards with light pencil lines. These reference lines help you glue up the entire case square. Clamp each shelf in place, without glue, and adjust it until it’s square to the case side. |

|

Glue the lower unit together with cauls and pipe clamps. The thick cauls distribute clamping pressure over the entire width of the side. Use short clamps to pull the shelves tight against the backboards. Align the shelves with the reference lines. Then tighten the pipe clamps. This story originally appeared in American Woodworker October 2000, issue #82. |

|

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.