Even though I have a small fortune

invested in tools, I always seem to be

short of wooden handscrew clamps.

But daydreaming about buying ten more of

these versatile tools runs smack into the

reality that such a purchase requires spending

anywhere from $200 to $450, depending

on the size of clamp. Ouch!Several years ago, I resolved to satisfy my

need for clamps by making my own, using

the chunks of this and that from my scrap

pile, which waxes and wanes with the seasons.

In September, this pile spills out across

the shop floor, but by late December, the

frigid Maine weather has reduced it to nothing.

Until spring, the morning race to get

some heat in the shop becomes a little like

the Mississippi River steamboat races of the

1800s, the crew dismantling cabins and

upper decks to provide fuel for the roaring

boilers. So, my rule of thumb is to make

clamps before the heating season starts.The first batch of clamps that I made

were similar to Jorgensen handscrews,

except for having wooden screws. I turned

maple and ash on my lathe to make my own

wooden screws, and threaded them with a

screw box. The resulting clamps worked

well, with one important exception: They

were a bear to adjust; cranking them open and shut was laborious. When a tricky glueup

was writhing on the bench like a crazed

anaconda, and speed was of the essence,

these clamps wouldn’t do.

Then, while flipping through a book I

purchased at a flea market, I spied two

wooden clamps in a photograph taken at

Old Sturbridge Village in Massachusetts.

These clamps were similar to the ones I had

made, with a crucial difference. Where both

screws on my early clamps threaded completely

through the opposing jaw, the Sturbridge

examples had one screw that passed

through the threads and one that seated in

a stopped hole. Both screws were secured

to this jaw with garters. So as the screws

turned, they either forced the jaws open or

pulled them closed. Shouting the (unprintable)

Maine equivalent of “Eureka,” I

rushed to the shop to build a prototype.

There must be an unwritten rule sacred to

cabinetmakers (at least to me, anyway), that

the paying work isn’t nearly as interesting

as the harebrained schemes that we invent.

Several hours later, I held in my hands a

clamp which effortlessly twirled open and

shut. Here’s how to make your own wooden

handscrews, like the one I devised.

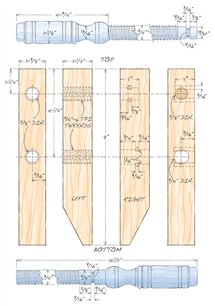

Make the jaws

I usually make these clamps in batches.

Start by milling and sawing kiln dried stock

for the jaws. The dimensions for each jaw

block are 1-3/8″ wide on the clamping face,

1-1/2″ inches thick, and 9″ long. Arrange

the blocks in pairs and mark the outer side

or cheek of each pair with a triangle that

points to the mouth of the clamp (1). Open

each pair of blocks to their clamping faces

and mark two points on one, 1-1/4″ and 4-

1/2″ from the back end. Hold the blocks

together, with their ends flush, and use a

square to strike lines across both faces, running

through the points you’ve marked.

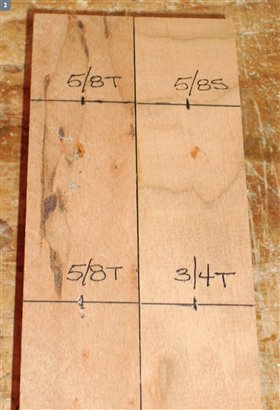

Mark the center of each line to locate the

screw holes. Then label the diameters and

indicate whether the holes go through or

are stopped (2). Taking this step avoids confusion

if you make these clamps in multiples.

Also, mark the jaw faces “left” and

“right” and “top” and “bottom.”

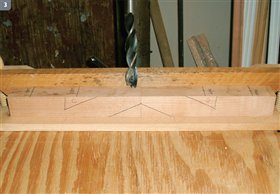

Chuck a 5/8″ brad point bit into your

drill press and position a fence so the bit’s

point lines up with the center points you’ve

marked on the jaw block. Always keep the

marked cheeks of each pair of jaw blocks

pointing outwards (3). This ensures that

the drilled holes will be equidistant from

the fence in each block, so that the holes—

and the jaws—will be coplanar when the

clamps are assembled.

If you’re making a batch of handscrews,

now is the time to clamp a temporary stop

block to the fence, to ensure that holes are

drilled consistently in each set of blocks.

Place the left jaw blank on the table, against

the fence. Bring the bit down and align its

point with the mark that’s nearest the

block’s top end. Clamp the stop block

behind the jaw block.

Drill a 5/8″ hole completely through the

block. This will become the threaded hole

for the top screw. After drilling matching

holes in all your remaining left jaw blocks,

reset the stop block and drill the second

(lower) hole in each left block.

Remove the stop block and reset the

depth stop to drill the 5/8″ x 1″ deep

stopped hole in each right jaw block. Place

the right jaw, clamping-face up and marked

cheek out, against the fence, with the brad

point centered on the location of the top

hole. Install the stop block and drill the 1″

deep hole. Do the same for any other right jaw blocks. Install a 3/4″ brad point bit,

reposition the stop block and drill a 3/4″

inch hole completely through the jaw block

at the location of the lower screw. You

should now have left jaws with two through

5/8″ holes and right jaws with one stopped

5/8″ hole, and one 3/4″ through hole (4).

Clamp each left jaw block clamping-face

up in your bench’s shoulder vise. Then,

using a 3/4″ tap, carefully tap both 5/8″

holes (5) to accept the 3/4″ dia. screws you

will make next. A 3/4″ woodthreading kit

(tap and thread box) is available from

Woodcraft (#12T14). Note: I start with 5/8″

dia. holes, because the root diameter of my

tap is 19/32″. The holes’ additional 1/32″

dia. make it easier to get the cutter started.

Check your tap’s root diameter and adjust

the size of the starter holes you drill, if necessary.

Cut the angled face on the outside corners

of each pair of jaw blocks to form the

clamp’s mouth (6). Clean up the angled

cuts with a disc or belt sander. Finish the

jaws by easing the outside edges with a 45°

chamfer router bit.

Turn the screws

I have lots of split-off pieces of green

maple and ash lying around, because I primarily

make Windsor chairs. I turn my

screws from this leftover material, because

it turns and threads easily. I split out 1-3/8″

to 1-1/2″ square billets, trim them to 16″

lengths and turn them on my lathe to 1-

1/8″ dia. Then I mark out the handle, allowing

for some waste on the end. My handles

are based on the profile of the handles on

a set of chisels of which I am particularly

fond (7). Personalize your clamps by turning

the shape of your handle as you wish.

Turn the remainder of the shaft to 3/4″ dia.

I have always found it best to turn my screw

shafts slightly undersize at this stage. Whether

or not my calipers are slightly out of sync with

my drill bits (and every other blessed thing),

it is a fact that a shaft that’s turned too large

will bind when its fed into a screw box. So

don’t get fixated on being overly precise (see

“Performance vs. Art,” below).

Mark out and cut the grooves in the

screws that will engage the garters in the jaws

when the clamp is assembled. Notice that

these grooves are located at opposite ends of

the two screws. On the lower screw (the one

that installs nearest the jaw mouth), the

groove is located near the handle (8). On the

top screw, the slot is on the opposite end. I

turn the end of this screw down to just

under 5/8″ dia., and then cut the garter

groove. This section should be a little longer

than 1″, to allow for trimming.

Thread the screws

Cutting the threads is a simple process,

because green wood works so easily.

Clamp the screw in your bench’s shoulder

vise, shaft up. This frees up both hands to

turn the screw box. The box’s guide (or starter) block keeps the shaft aligned with

the thread cutter as you start to feed the

work into the tool. The threads on the bottom

screw run from its tip to the flat section

that precedes the garter groove (9).

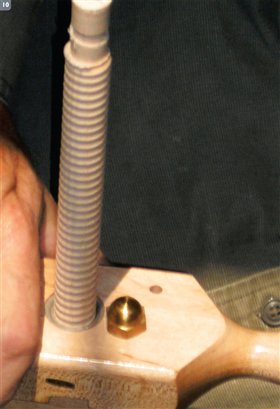

The top screw threads start beyond the

garter section on the end and extend all the

way to the handle (10). The screw box’s

guide block will bottom out against the handle

before the last threads can be cut; the

block must be removed to finish the job.

First, back the screw box off the threaded

portion of the shaft. Then unscrew its guide

block. Removing this block exposes the Vcutter

that actually cuts the threads. Take the

partially-threaded screw out of the vise and

rethread it into the screw box: Carefully turn

the screw by hand, until its threads engage

the screw box’s threaded body. Then turn

the screw box like a nut to move it down the

threaded shaft. The exposed V-cutter will

engage the final unthreaded section and cut

threads very close to the handle before it

bottoms out (11).

Before you try out your newly threaded

screws, set them aside for a week to dry out.

They will shrink enough in diameter to

turn easily in the threaded jaws. If you are

working with kiln dried stock, you don’t

have to wait, but you may have to run the

threads back and forth through the screw

box several times, and do the same with the

tapped jaws, to get a looser fit (see “Kiln

Dried Screws, below). Loose is good.

Remember that threads are really spiral

wedges, so they tighten as they close. A

loose fit allows the clamps to twirl easily

when you are adjusting them.

Assembly

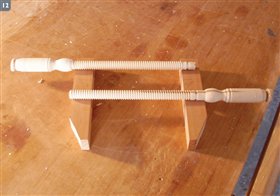

Make sure the non-threaded 3/4″ and

5/8″ dia. portions of the screws fit smoothly

in the appropriate holes drilled in the jaws.

Resize the shafts, if necessary. Test fit both

screws to ensure that the two jaws will seat

tightly together when closed (12). First, seat

the 5/8″ end of the top screw into its

stopped hole in the jaw. Then trim the end,

if necessary, until the threads seat against

the jaw’s clamping face. Next, test the nonthreaded

portion of the lower screw in its

3/4″ dia. hole. The threads should extend

slightly into the jaw’s body. If necessary,

take another turn with the screw box. But

be careful not to cut the threads too close

to the garter grooves. (Clamping puts pressure

against the garters, which in turn put

a lot of pressure on the garter groove shoulders—

they can break out if there isn’t

enough heft between the threads and

groove.) Complete the screws by trimming

the waste off the end of the handles.

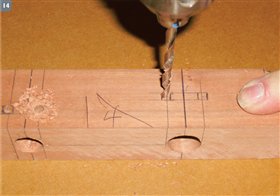

Mark the location of the garters for both

holes in the right jaw. The best way to do

this is to lay each screw in place on the jaw

and tick off the garter locations with a pencil

(13). I drill 3/16″ x 1″ deep holes (14),

being careful that they are far enough apart

so that the garters (3/16″ square pins that are driven in) don’t rub or bind the screw

shaft as it turns. I aim for the garters to protrude

1/16″ to 3/32″. Any less, and the screw

grinds the garter to dust and runs over it.

Any more, and the shaft binds when the

screw is turned. When I have an overly tight

garter, I have two choices: keep working the

screw back and forth until the garter and

screw wear in, or be patient and wait until

the green screw shrinks a bit more.

Make the 3/16″-square garter pins out of

any available hardwood. I cut mine about

1-1/2″ inches long. Thread both screws onto

the jaws and seat both garter sections. Then

drive the garter pins into the round holes

and trim them flush. Finally, clamp the

assembled handscrew on your workbench

and belt sand both sides until the jaws are

flush. This removes any misalignment introduced

when the holes in the jaws were

machined at the start of the project. Once

you have made one handscrew, you can use

the same technique to create them in any

size. The process is the same. |

|

Click any image to view a larger version

Performance vs. Art

First and foremost, these clamps are tools which I expect

to put to hard use in my shop. I have gotten to the point where

I no longer sand the screw handles, or do more to the assembled

clamps than give them a quick pass or two with a beltsander

to flush up the sides of the jaws when the clamp is

closed. I find that the turning-tool marks, left unsanded on the

handles, add to their “grippyness.” I also don’t worry about wane,

small checks or other defects in my handles, because the screw

doesn’t have to be visually perfect to work. In the same vein,

small chip-outs in the wooden threads are acceptable, because

a screw thread is, in reality, an inclined plane. Even with small

chip-outs, there is still a lot of bearing surface between the male

and female threads of the screw and jaw. Only if a number of

adjacent rows of threads are chipped out or broken off is the

screw ruined.

Kiln Dried Screws

Green wood cuts like a dream, but dry stock can be both

tough and brittle. Threads can chip off if the wood is really dry.

If you use kiln-dried material for screws you can (1) either run

the threaded tap back and forth through the threaded jaw while

applying side pressure, to help open up the width of the

threaded opening, or (2) carefully adjust the depth of the V-cutter

in the thread box itself, so it cuts deeper while threading.

Another option is to liberally wipe the screw shaft with turpentine

before you cut the threads—I’ve found that wetting the

wood this way helps the screw box cut more cleanly. |