We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

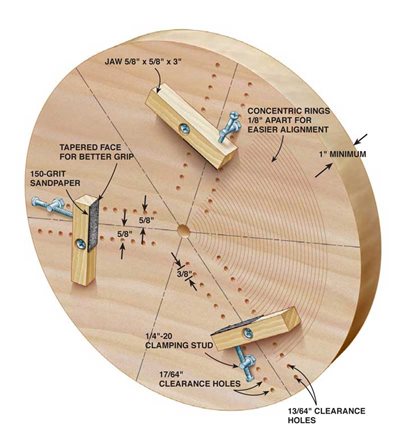

Shop-Built 3-Jaw-Chuck

A cheap, effective turning tool.

| Three-jaw lathe chucks are virtually indispensable for a turner, yet the cost of buying one can be prohibitive. Three-jaw chucks are useful when turning small pieces at low speed, and permit multi-axis turning. This shop-made chuck can be made from scraps of maple and a few machine screws. By changing the arrangement of the screw holes, this can also be made into a 4-jaw chuck. The jaws are positioned in a |

Click any image to view a larger version. |

| This story originally appeared in American Woodworker August 1999, issue #74. |

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.