We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Making Curved Doors

Kerfkore flexible panels

handle curves with ease.

By Brad Holden

|

Curved doors and panels add elegance There are several important tricks and techniques

What is Kerfkore?Kerfkore is a very Kerfkore with paper backer on both sides is also Kerfkore comes in 4-ft. by 8-ft. sheets in 1/4-in., 3/8-in., |

Click any image to view a larger version. Kerfkore flexes Doors made with Kerfkore have |

Pick your veneer

1. Your three main veneer choices are two-ply wood |

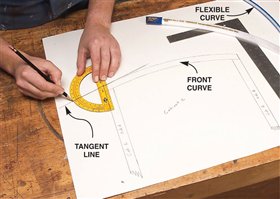

Make a full-size drawing

|

Apply the front veneer first

|

Add solid-wood edges for strength, appearance

4. Solid-wood strips provide durable finished edges |

Cut the edges to the required angle

|

Attach the back veneer with yellow wood glue

|

Attach the back veneer with a vacuum press

|

Trim the curved edges

|

Veneer the ends and trim flush

|

SourcesNote: Product availability and prices are subject to change. Kerfkore Co., kerfkore.com, 800-637-3539, Kerfkore, 3/4 in. x 4 ft. x 8 ft. single-sided; 3/4 in. x 4 ft. x 8 ft. doublesided. Roarockit, roarockit.com, 416-938-4588, Thin Air Press kit vacuum press, #01301. This story originally appeared in American Woodworker September 2006, issue #123. |

|

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.