We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Create a thick, solid look for your cabinetry with a laminated plywood approach. This excerpt from “How to Build Bookcases and Bookshelves” covers a plywood sandwich construction technique that will give you the look of heavy solid panels for your furniture projects.

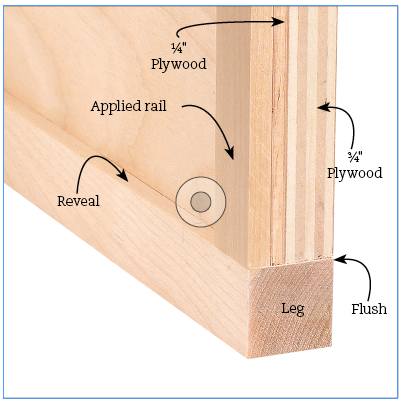

Sandwich construction uses readily available thicknesses of plywood to create thicker panels. It also lets you produce a panel that has two very good-looking sides because the best side of each piece of plywood faces outward. There are two basic ways to create a sandwich panel. The first is to simply glue two pieces of plywood back to back. This is the approach we used for the end panels in this bookcase shown here.

Sandwich construction works well for cabinet parts that will be fastened to other cabinet parts, such as the ends of this bookcase, which are biscuited and glued to the subtop and the bottom shelf. The reason for fastening these end panels is because the plywood parts that make up the panels are different thicknesses (1⁄4″ and 3⁄4″), so there is a risk of warping. However, if the sandwiched plywood parts are the same thickness, the chance of warping is greatly reduced. Such panels can even be used where they won’t be fastened down, as for cabinet doors or adjustable shelves. The second way to create a sandwiched panel is to use a center core with a layer of plywood glued to each side. The center core can be either a lumber frame or another piece of plywood. The lumber-frame approach has the advantage of letting you produce a panel of precise thickness that weighs less than one made with a plywood core. Either core will make a sandwich that is resistant to warping.

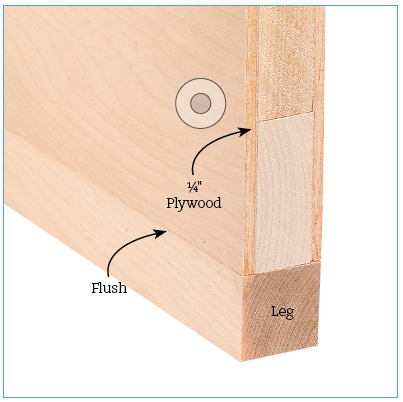

Gluing together a ¾” and a ¼” piece of plywood creates the end panels for the bookcase shown. This sandwiched panel is then trimmed to final size, and the legs and applied rails are added. The final result is an end panel that is flush on the inside with a frame-and-panel look on the outside.

Gluing two pieces of ¼” plywood over a lumber-frame core creates the center panel for the bookcase. This creates an extra-thick but lightweight panel that is exactly the same thickness as the legs. With a lumber frame on the inside, you can custom-make panels any thickness you want.

— Randy Johnson

For complete instructions for building this bow-front bookcase and for other great bookcase builds, check out “How to Build Bookcases & Bookshelves,” available now at shopwoodworking.com.

For complete instructions for building this bow-front bookcase and for other great bookcase builds, check out “How to Build Bookcases & Bookshelves,” available now at shopwoodworking.com.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.