We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

The float has arrived and is soon to be sharpened and used. In the meantime, and following on from the comment about the details of the plane, I’ll try and share some of the Mathieson magic. On that note: A very big thank you to anyone who has made the time to leave a comment on my posts. One of the things I enjoy most is discussion so please keep them coming!

I’ve contrasted Mr M with my “tidy” wooden jack that I typically use as a small trying plane rather than the fast stock remover I hope my Mathieson clone will become. The length of the two tools is the typical 17″ you would expect; also they both have tapered cutting irons with the addition of a cap iron. All as expected.

However, working on from there a few significant differences present themselves. First of all the pitch. Lining up both planes side by side the escapements line up perfectly.

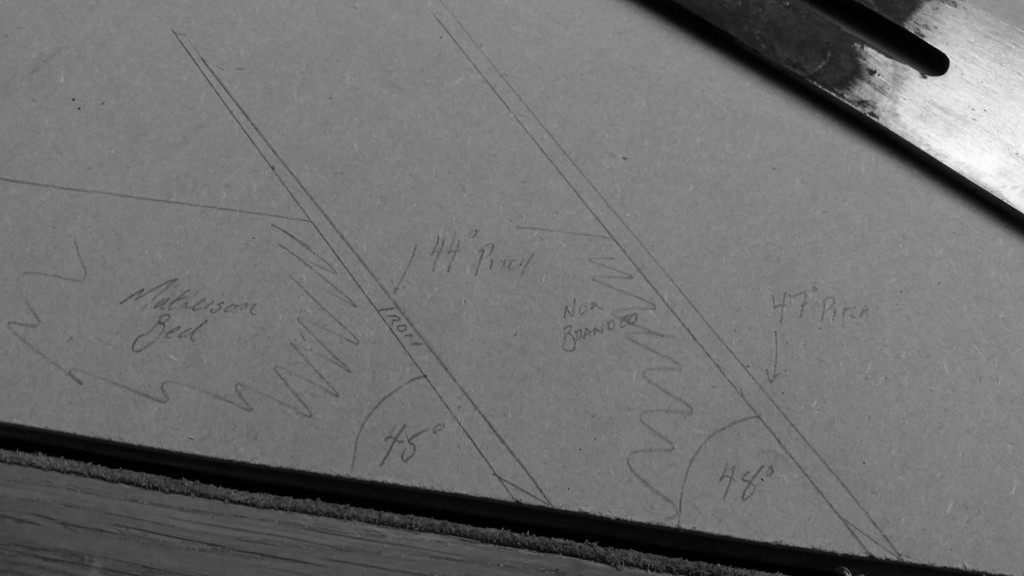

However, as is suggested by the photo, Mr M has a lower pitch, this is further confirmed when you see where the mouth terminates at the sole. I was interested to measure the bed angles and did so. The Matheison bed is 45° and my unbranded jack is 48°. I also drew around the cutting iron and, although very slight, the fact the cutting irons are tapered means it drops the effective pitch by a further degree of 0.5.

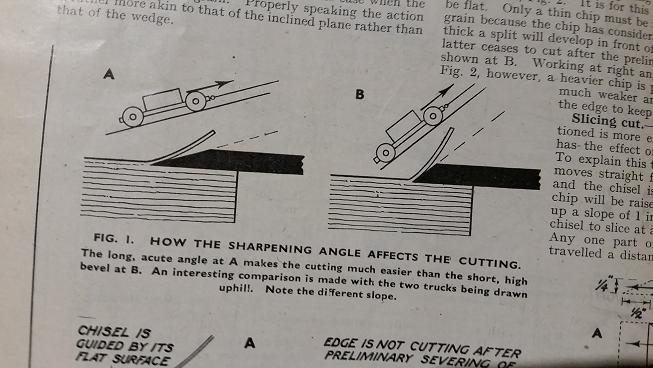

The fact that these two planes are well below the steeper typical bed angle of earlier planes is I think in no small measure due to the fantastic cap iron!

This advancement that is proven to offer excellent control of surface finish means a plane can be bedded at a lower angle allowing easier working on typical mild timbers. Doubtless this was a boon for intensive users day in day out

One of Charles Hayward’s sketches illustrates the point well; why work harder than you need to? When you need a finer surface, simply advance the cap iron – bliss! The handle of Mr M is a touch different as well – it’s closed. I think that looks nice, but regardless of that, it is shaped in such a way that makes my wrist less forward-leaning and more upright, more pushing forward than pushing down and forward. It’s be interesting to see how that works out and what I like using best.

On other matters Mr M is 2-7/8″ x 2-7/8″ with a 2″ cutting iron. Again, my hope is it’s slightly narrower iron, lighter weight and 45° bed angle will make for a very fast working tool. I’m looking forward to sharpening the float and moving things forward.

— Graham Haydon

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

I am truly amazed that sharpening a float is such a big deal to so many folks. I jumped in with both feet and made my own floats from some O-6 tool steel that I had. Cutting the blanks, filing the teeth, heat treating and then sharpening them. I had never done this before, but it was an interesting and satisfying process.

The instruction sheet on a float I bought this summer specifically said it needs to be sharpened.

The LN floats are precisely machined and then heat treated. During the heat treating process you get some surface distortion. To get the best performance from the floats they need to be sharpened (with a file, not hard to do), but they do work out of the box.

Now I’m a little scared to order my floats! I would have to assume that they should be sharp, just like you would expect a brand new saw to be sharp. As far as the plane, were you adding a tote? I missed the last post.

Thanks.

BIll

Graham,

Pick up the phone – someone at Lie Nielsen WILL be VERY helpful and sort this out for you whatever the problem!

A new float should NOT need to be sharpened. It needs to be returned.

I’m in agreeance with Mike. A brand new float from Lie-Nielsen doesnt need to be sharpened. I should know; I own almost a dozen of them. They work great!

Hi,

I’m confused – why do you have to sharpen a brand new float?

And I guess, how would you do that?

Mike Dyer