We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

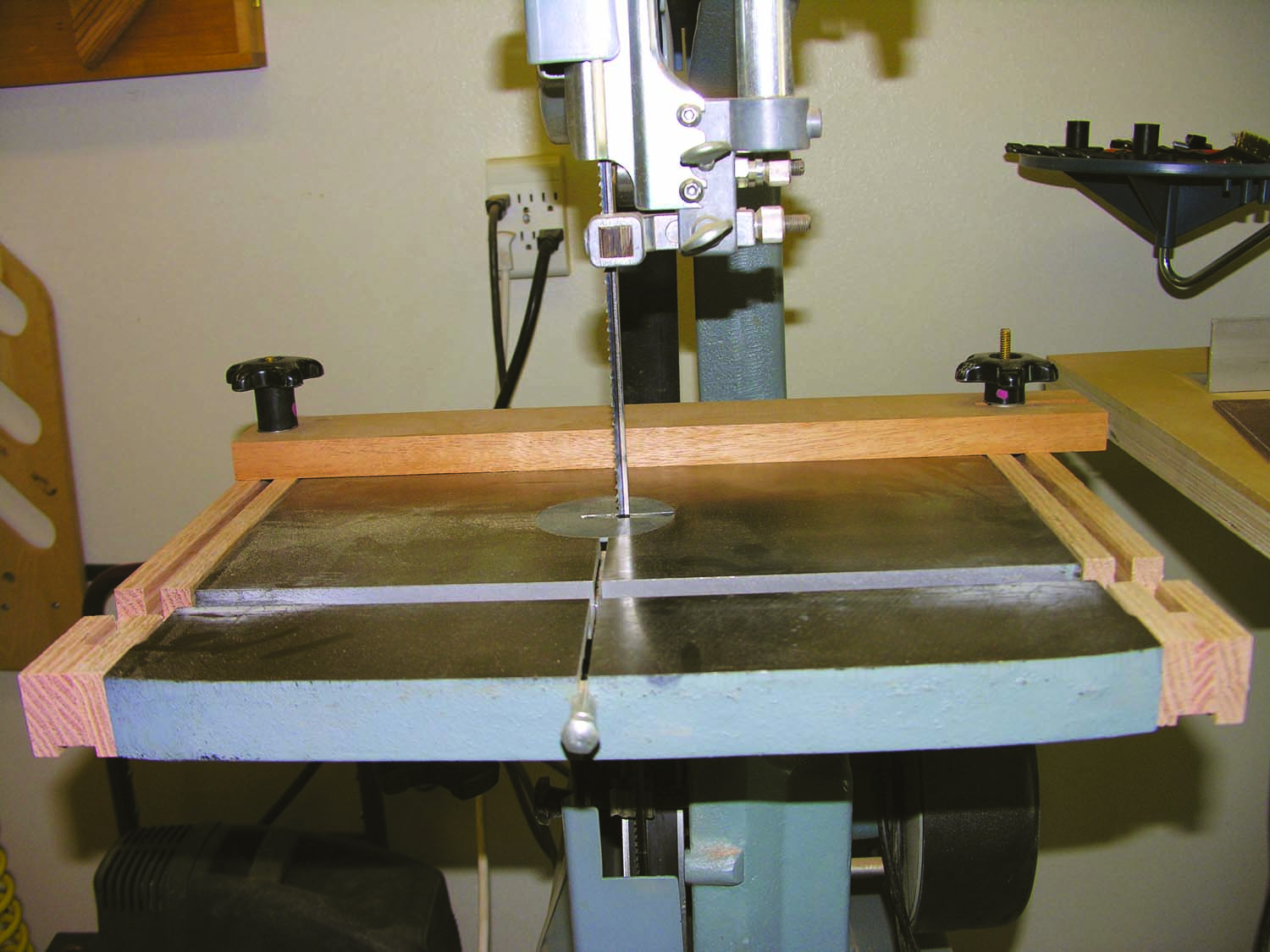

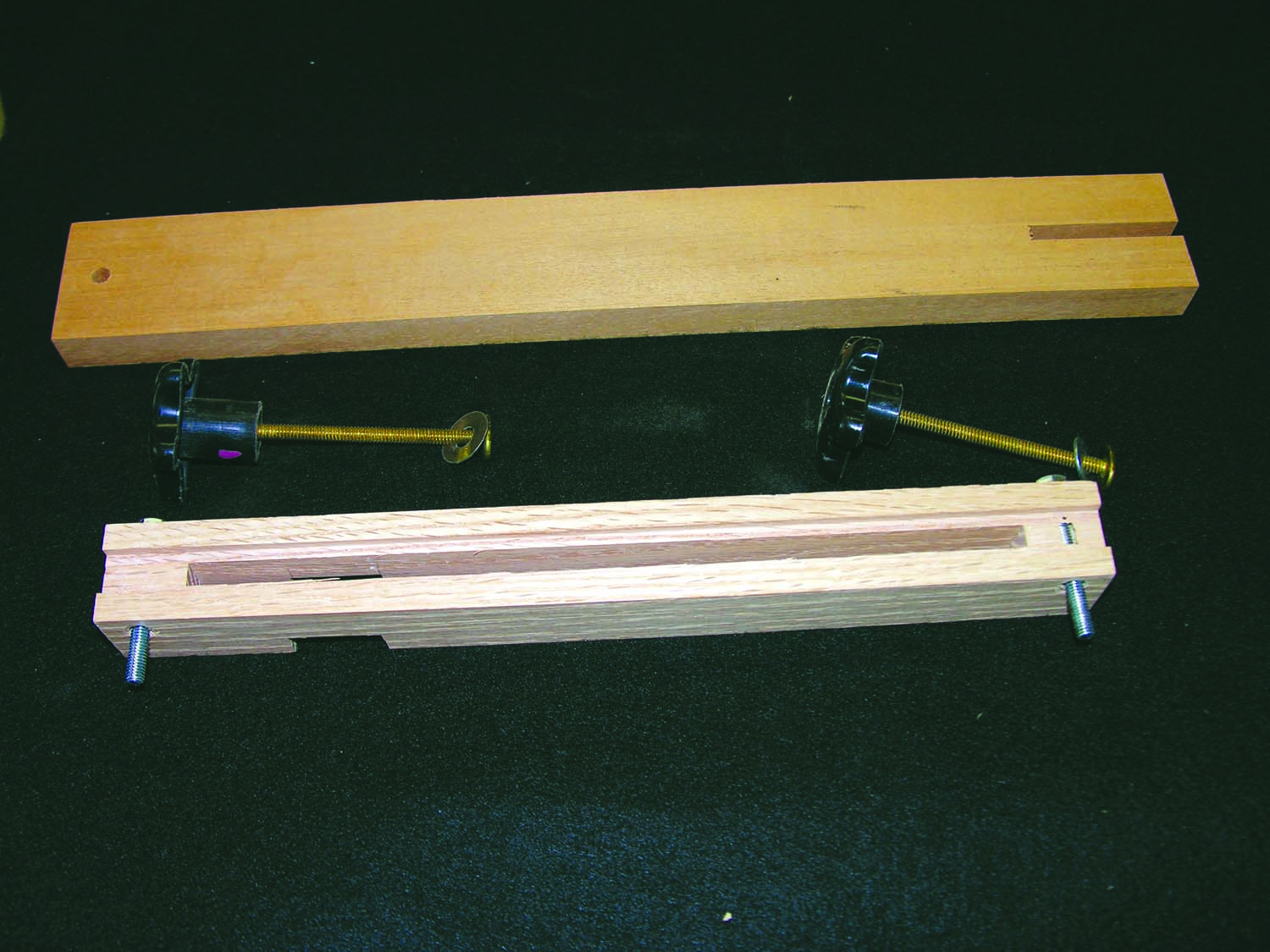

Unsatisfactory bandsaw fence? This simple shop-made fence and track system could be the answer. The tracks are formed by gluing up three pieces of hardwood. A slotted fence provides adjustment for blade drift, and is locked in place at any angle using T-bolts and jig knobs.

To make the tracks, cut two pieces of hardwood 2″ x 1-1/4″ and the same length as your table’s width. Cut a centered 3/4″ wide by 1/4″ deep groove in one 2″ face of each piece. This creates the recess for the T-bolt’s head to keep it from turning. Rip each of these pieces in half, down the center of the grooves, so you have four 7/8″ wide strips, each with a rabbet along one edge. Make a notch through all of the strips in alignment with your saw’s miter gauge slot. The notch needs to be dimensioned so that when the tracks are mounted to the table, your miter gauge’s bar can pass through.

Glue 5/16″ thick x 1-1/4″ square spacers in between each pair of mounting strips. Drill mounting holes through the tracks’ ends and spacers, and mating holes through the table’s edges. Bolt the tracks in place.

Glue 5/16″ thick x 1-1/4″ square spacers in between each pair of mounting strips. Drill mounting holes through the tracks’ ends and spacers, and mating holes through the table’s edges. Bolt the tracks in place.

The only downside – and I’m still looking for the best solution – is that each time I move the fence I need to re-square it to the blade. -Len Urban

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.