We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

I had to crosscut narrow strips to make a cutting board. The boards were too wide for my miter saw, so I decided to use my tablesaw’s crosscut sled. I tried a standard stop, but after a few cuts, I realized that the parts were “creeping” ever so slightly during the cut. I needed a stop that actually held the parts in place.

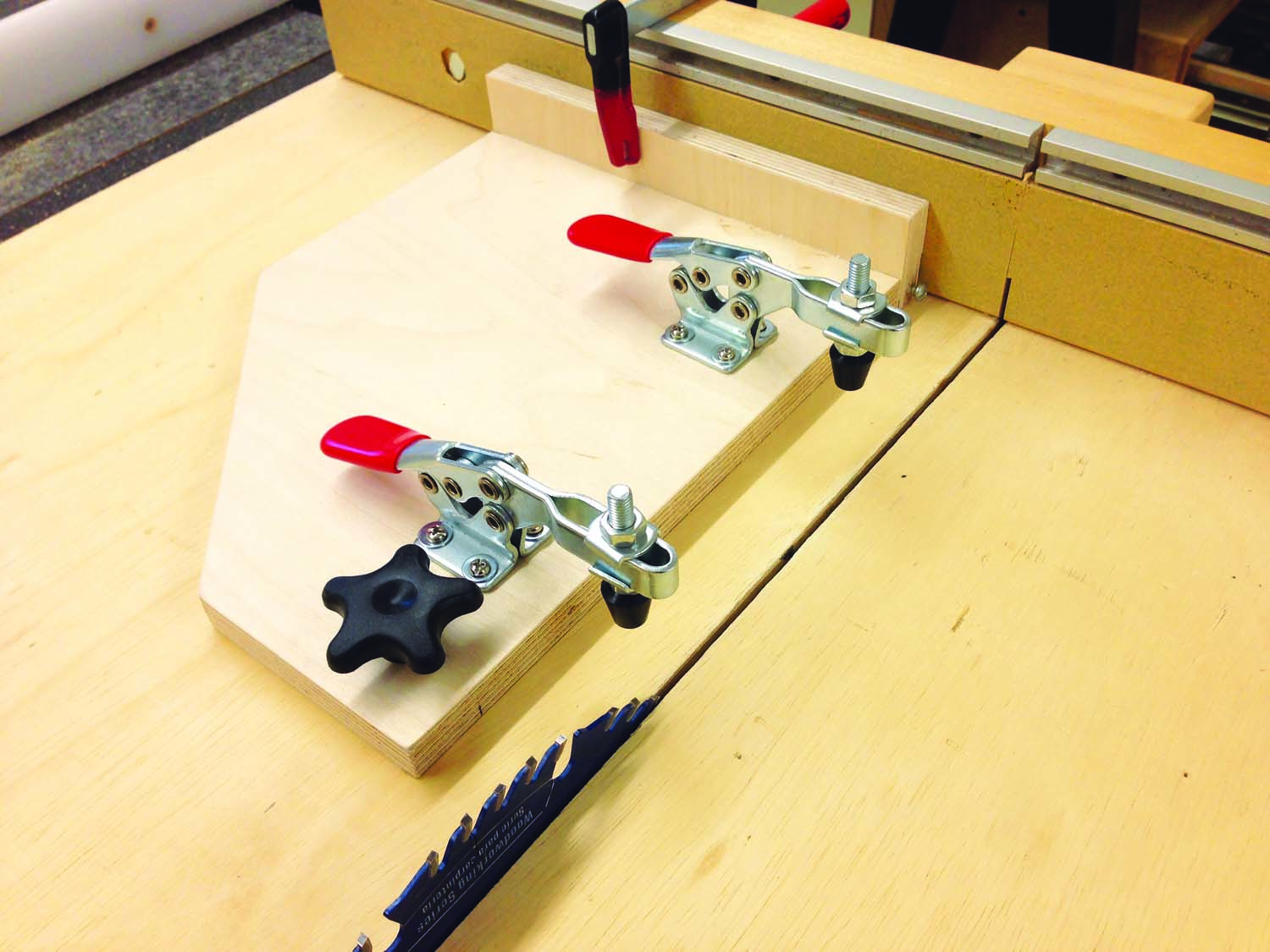

To solve the problem, I made this fixture that acts as both a stop block and a hold-down. It clamps right to my crosscut sled’s fence.

The fixture is made from two pieces of 3/4″ plywood, and uses two toggle clamps to hold my work securely. An F-style clamp holds the fixture’s back square against my crosscut sled’s fence. The front end is secured by a jig-knob and a threaded insert installed in my crosscut sled. A slot for the jig-knob’s stud allows for width adjustments.

I did run into one problem. Because of the fixture’s size, the edge in contact with the workpiece is quite long, creating a trap for dust. So I installed a screw in the fixture’s back corner. My workpiece just butts up to the screw, creating a generous gap so dust build-up doesn’t interfere with the cut. When the stock gets short – less than 3″ – I install another screw at the jig’s front end to keep the cut square. -Cory Hoehn