We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

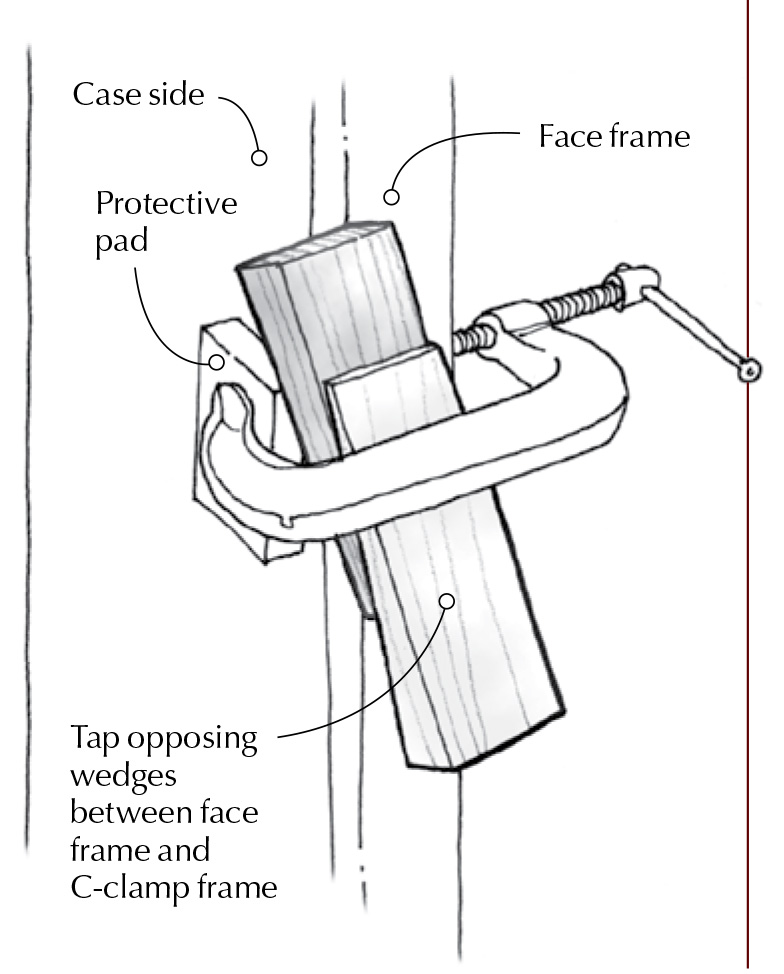

I made a built-in bookcase for my daughter that required attaching the face frame after installing the case. I didn’t want to mar the face frame with nail holes, but I don’t have any special-purpose edge clamps and didn’t want to buy a bunch for this single application. I remembered seeing wedges used for various clamping purposes, and decided to put them to work here along with standard C-clamps.

I found that by squeezing the clamps against the case sides (with protective pads underneath), I could tap opposing wedges under the clamp frame to apply pressure against the face frame. Packs of wedges are available at home-supply centers, or you can make your own on the band saw using scrap wood. — Steve McDaniel

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

I use wedges a lot when clamping, especially to flatten bowing on edge to edge glue ups with pipe clamps. Use a straight edge to determine flat, and tap wedges between the pipes and the boards. There is no need for opposing wedges.