We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Safety is #1 in the workshop.

Safety is #1 in the workshop.

Before you’re ready to lift a single hammer or cut a single board, you’re going to want to understand the impact of safety in the shop. Accidents can happen to anyone, even the most careful of us out there, so taking the appropriate precautions can mean the difference between losing a fingertip and a whole hand. Not to mention the long-term health complications that can arise from poor use of protective equipment. While this guide on PPE is far from comprehensive, it’s a good start to a long, healthy life

of woodworking.

Use the code BASIC25 to save 25% off your first month or full year of PopWood+, which now includes access to the latest issue of the magazine, exclusively for members.

Personal Protective Equipment (PPE)

PPE is the first line of defense in the shop. You should always be protecting your eyes, ears, and lungs while woodworking. You may not see it all the time in photos in the magazine, but believe us that we always have our PPE on behind the scenes.

1 Safety glasses come in all shapes and sizes.

For Eyes…

Safety glasses are my number one safety device in the shop. I treasure the use of my eyes far too much to risk anything happening to them. While I’m almost always wearing my personal glasses that are impact-resistant, I still take the precaution of throwing on real safety glasses whenever the need arises. You literally cannot have too many pairs of these, and you can buy ANSI-certified glasses at the home center for less than $5. Whenever I lose track of the pair I was most recently wearing (which is often) I go grab a fresh set off the pegboard on the wall.

2 I prefer in-the-ear hearing protection, but earmuffs work great too.

…and Ears

This is another one I always have on. I’ve noticed that lack of hearing protection causes the most immediate discomfort. Just running a few boards through the table saw without protection will cause short-term ringing, not to mention long-term hearing loss. I also enjoy listening to music while I woodwork, but I make sure to keep the volume low enough that I can still hear what my tools are doing. Often the blade, bit, or motor will tell you audibly when it’s struggling before it suffers a more serious failure.

3 Fit your mask to your task; the finer or more dangerous the particle, the better the mask should be. The level of protection these masks provide increases from left to right.

Don’t Forget the Lungs

When considering long-term risks, you can’t forget to take care of your lungs. You don’t need fancy dust collectors for this, even a basic N95 or KN95 will go a long way toward protecting your lungs. Even better yet is an upgrade to a high-quality respirator, especially during finishing work. That being said, I do think finding a way to collect dust at the source is a very worthwhile investment though, and will help keep it out of the living areas of your home. Check out a rundown of dust extractors at different price points.

4 Gloves in the shop are a no-go for most tasks.

Protect Your Body Too

A sometimes-overlooked aspect of PPE is the clothing for the rest of your body. Composite-toe boots are especially important if you’re working with large pieces of lumber or sawmilling. And don’t forget industrial-quality pants and shirts to protect yourself from scratches and sharp edges. That being said, I don’t encourage gloves in the shop. While there are certain scenarios where they can be beneficial, they are a catch risk when working with high-speed blades.

What the heck are all these acronyms?

You might have noticed that many types of safety devices are labeled with ANSI or NIOSH certification numbers. But what do they mean, and does it matter?

ANSI stands for the American National Standards Institute, a nonprofit organization which was founded in 1918 to lay out operation standards for equipment.

NIOSH is the National Institute for Occupational Safety and Health, a United States federal agency mostly dealing with workplace safety from the standpoint of exposure to harmful substances.

There are a few additional agencies certifying other industry-specific workwear that we won’t cover, but the premise works the same for all of them. Basically, any PPE item that has been certified meets or exceeds certain standards laid out to protect the user.

Equipment that is certified isn’t guaranteed to be better at protecting you than a product that lacks certification, but it does mean that the product has undergone testing to meet a minimum level of protection. Likewise, a non-certified piece of safety equipment doesn’t mean you’re in additional danger, just that you don’t have a set level to compare it to.

Let’s use a non-NIOSH-certified dust mask for example. The filtration itself might be of equal or better quality than the standard, but if it doesn’t reach the minimum requirements for a tight fit on the face, it won’t pass. Certifications can help give peace of mind that you’re getting the full protection package.

As a general guideline, you should shop for PPE that is safety certified. I will say that I make occasional exceptions. I might have normal earbuds in while running a more quiet machine. Or when I’m sweeping the shop I’ll throw on a more comfortable mask. Ultimately, even lower standard safety gear is better than none at all.

Bonus PPE Push Blocks

I’m going to add something to the usual realm of PPE in the shop: push blocks. While most safety features of the tools in your shop are integrated to the tool itself, push devices are standalone items that become an extension of your person. After all, the real endgame of woodworking is to finish your project with the same number of digits as you started. The easiest way to achieve that goal is to keep said digits as far away from sharp-moving blades as possible.

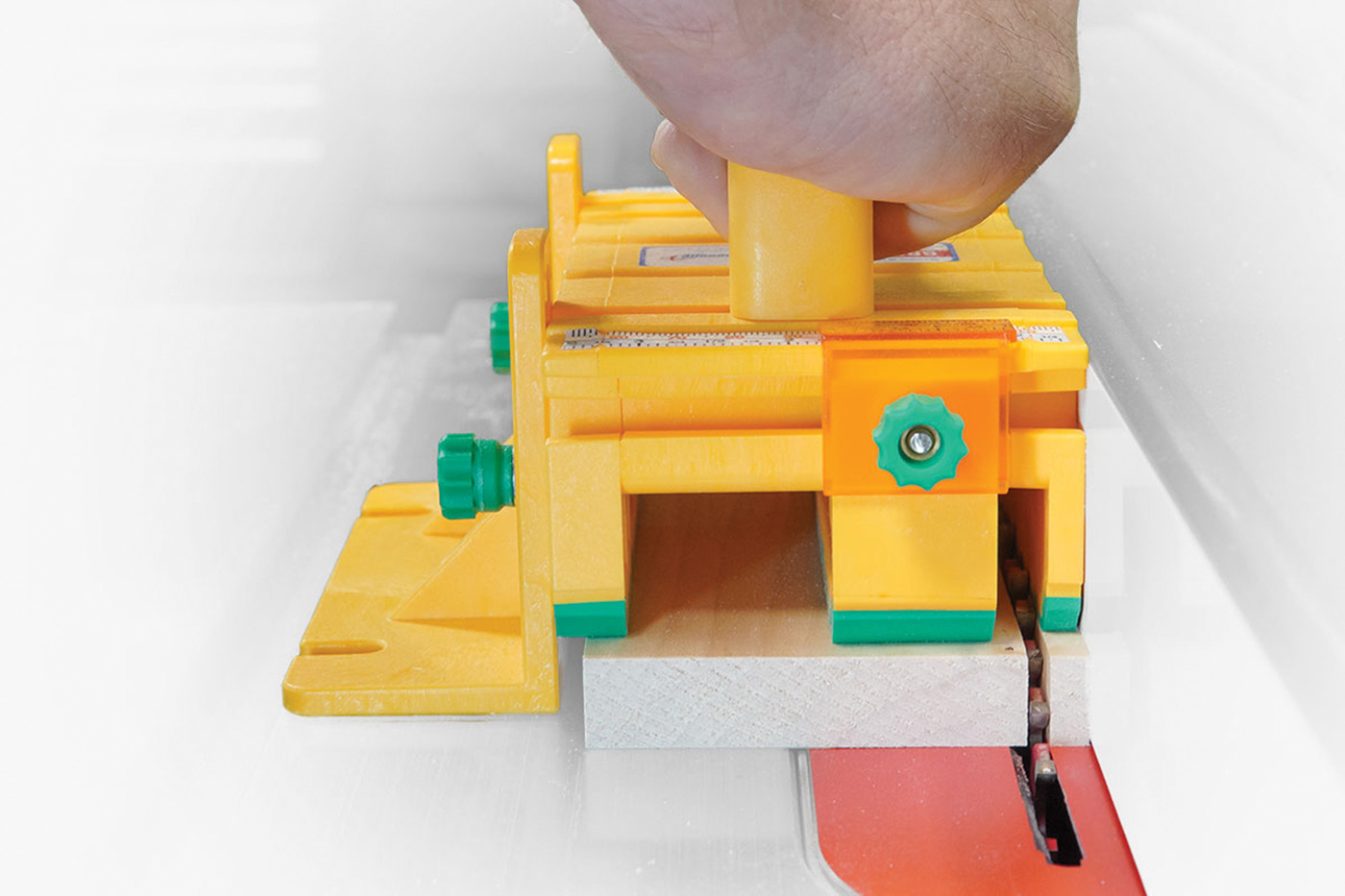

5 The Microjig Grr-ripper provides a high level of control of the workpiece, while also keeping your hand well out of harm’s way.

Previously you could categorize push devices into two separate fields—sticks and blocks. Push sticks help you maneuver wood in tighter spaces, like between a blade and a fence. Push blocks (or push pads) work great for holding down stock while jointing or at the router table. There are some new options out there from companies like Microjig and Milescraft that allow a bit of a hybrid approach. Strategically-placed channels allow you to hold the entire workpiece steady even with a blade running through. Personally, I think you should find whatever sort of device you’re comfortable using and to always keep it nearby when making cuts.

Non-PPE

Safety in the shop doesn’t stop with your personal equipment. Modern tools have numerous built-in safeguards that will help protect you—if you use them. You’ll notice this section is heavily weighted towards table saw safety. It is, without a doubt, the most likely tool to harm you in your shop. One study that 42% of reported woodworking injuries were caused by table saws and that they were the cause of the highest proportion of amputations at 39%. Another study found that table saws were responsible for 20% of non-occupational amputations, more than any other single consumer product.

Riving Knives & Splitters

While your brain is the biggest safety feature in the shop the biggest safety feature on your saw is the much more humble riving knife. As many as 90% of table saw accidents happen around kickback, which is where the board becomes bound on the blade (or between the blade and another stationary object) and is thrown back towards the operator. Kickback happens lightning fast and entirely unpredictably. Sometimes the action of the board jerking will pull hands and fingers into the saw; other times it will launch the board at 100mph backwards towards anyone standing in the way.

6 A riving knife is the single biggest safety feature built into your table saw.

The best way to prevent this from happening is also devilishly easy—a piece of metal that helps prevent the board from becoming bound. All modern table saws include a riving knife, and it should always be used, unless you have a dado stack installed.

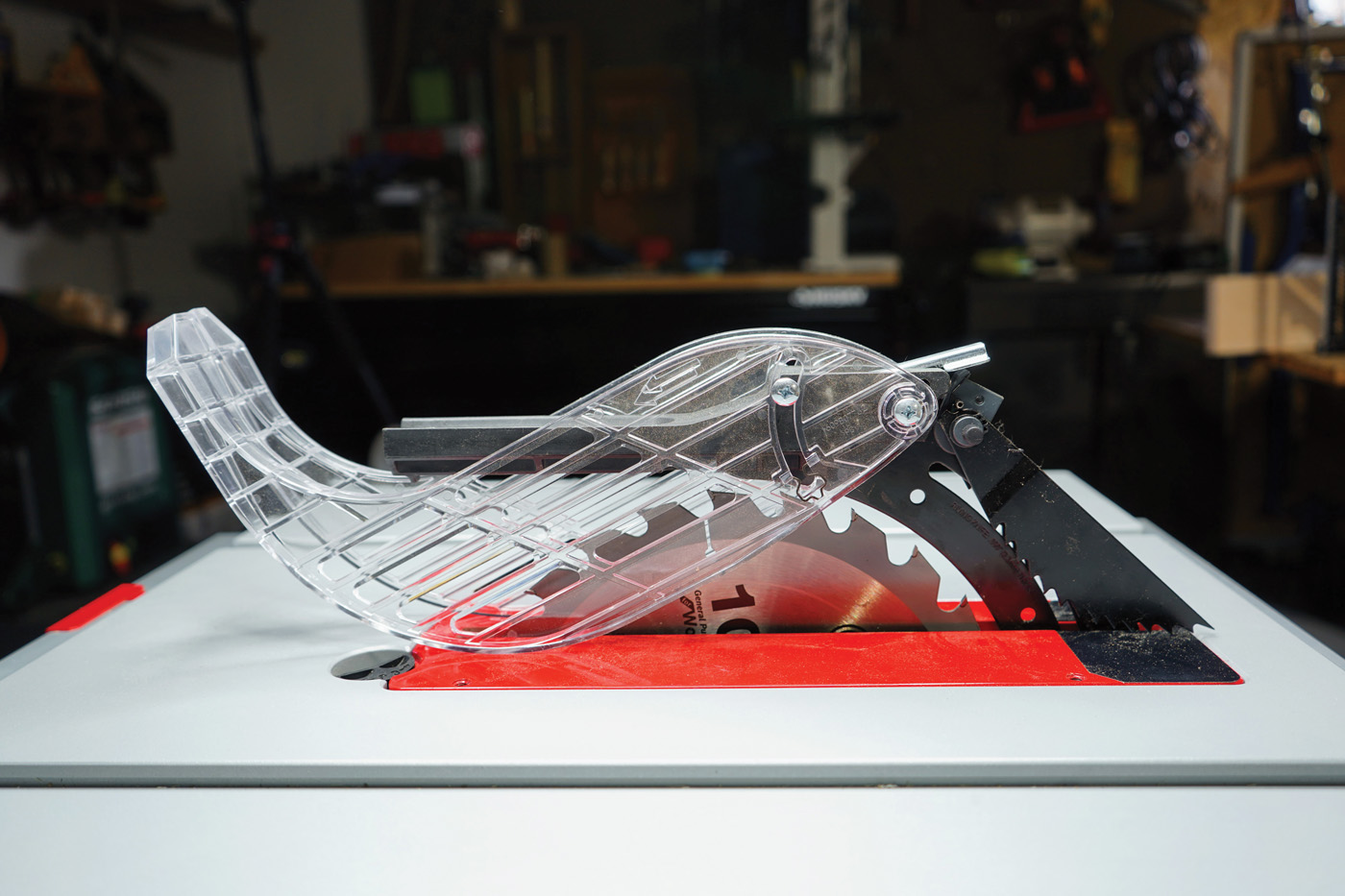

7 This mechanism includes a riving knife with an optional blade guard and pawls. I used as many of them as possible when making cuts.

Guards and Pawls

Also important, but far more cumbersome, are blade guards and pawls. The guards, which are often clear plastic, work great for preventing accidental contact with the blade. Pawls are the spiky things you see on the right side of the photo on the opposite page. They are intended to catch the board during a kickback event to prevent it from being flung.

8 This blade guard floats above the table and sucks dust away. It also means I can use accessories like a miter gauge with the guard in place.

There are some drawbacks to these safeguards though. The guard can make it difficult to see your cut, and they often get in the way of push blocks. They also can’t be used in narrow cuts as there is limited room between the blade and fence. I try and keep my blade guard in place as much as possible, but if I’m forced to choose between using the guard and using the push block, the push block takes priority for me.

Featherboards

Ever wish you had an extra hand in the shop? Maybe you just need to try using a featherboard.

9 Using a featherboard ensures a tight fit to the fence and leaves both hands free for feeding the board and a push pad.

A featherboard is a clever device that both applies pressure to the board, like that extra hand, but is also designed to help prevent or reduce kickback by not allowing the workpiece to move in a backwards direction. While not quite as effective as a riving knife from a safety standpoint, featherboards are easy to make, inexpensive to buy, and very handy.

Soft Start

One of the newest safety features on power tools is soft start motors. Like the term implies, the tool’s motor will take a second or two to spool up before reaching maximum power. This both prevents the tool from bucking or kicking, as well as giving you one last second to make sure everything else is set up in a safe manner.

Lastly, Think First

Probably the best way to keep yourself safe while woodworking is mindfulness. It’s very easy to slip into a routine task without much thought. Taking a split second to run a checklist through your mind is the antidote to this problem. Are you wearing your PPE? Are the blade guards in place? Is your push stick within easy reach? What about your hands—are they placed in such a way to be clear of any spinning blades or slipping chisels? Is your body positioned to the side of the blade if there’s kickback? If you feel rushed or uncertain, take an extra moment to cool your head before proceeding. Your woodworking project taking more time won’t hurt anyone, but if you make a mistake there’s a real chance you’ll hurt yourself.