We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

This shaping powerhouse has fallen out of favor of router tables, but in some instances, it may be the better tool in your shop.

This shaping powerhouse has fallen out of favor of router tables, but in some instances, it may be the better tool in your shop.

When it comes to being a jack of all trades, the router table may be king in the shop. From joinery to shaping, they do it all. However, in my opinion, there’s a cousin of the router table that may be even more versatile. And that is the shaper. If you’d look back 20 or 30 years, I’d wager that you’d find as many shapers in shops as router tables. However, the advances in router motors and lifts pushed many shapers out of the shop. But that shouldn’t have been the case. There are many situations where you may be better off with a shaper versus a router table. Yes, I’ll admit that shapers are generally a production-geared tool. They are designed for all-day use, cutting raised panels and doing production work. However, you don’t need to run a cabinet shop to take advantage of a shaper.

Like a Router, But Not

On the surface, a router table and a shaper do the same thing—they spin a cutter. The biggest differences are the bits, the bit holding, and the power behind the machine. Let’s put it this way. Picture the router table as your commuter sedan. It gets you to and from work. The shaper, however, is an 18-wheeler. Sure, it can be a daily driver, however there’s signifigantly more power behind it. When you must haul a trailer full of freight (or spin a big profile cutter), the 18-wheeler will do it whereas a sedan will not. A shaper is like that—it will spin a big bit with enough power to make a full cut.

1 Shapers utilize a spindle to hold the cutters. Modern shapers will have replaceable spindles, and even router collet spindles.

When looking at a shaper or shaper cutter, the most significant and noticeable difference is the bit (cutter) and cutter holding mechanism. As you can see in photo 1 above, shapers use a spindle to hold bits. My Harvey shaper came with three different ones to choose from — a 3/4“ spindle, a 1-1/4“ spindle, and a router collet spindle. These spindles are shafts that attach to the motor (with a drawbar), and the cutter slips over the shaft. Spacers are used to pinch the bit between the washer and the spindle base. On this Alpha, the router collet is an ER style to accept standard router bits.

As I mentioned before, shapers are powerhouses. They pack a lot of torque under the hood. Like an 18-wheeler, they have limited speeds. As you can see in photo 2, the speeds available on shapers are much lower than on routers. This is because the bits they spin are much larger, so the surface speed at which the outermost edge spins is significantly faster (therefore requiring lower RPM). This can potentially be a limiting factor using standard router bits in a shaper, but I haven’t run into that problem yet.

2 A variety of speeds as well as forward and reverse are conveniences of modern machines.

Also, note the control box in photo 2. There’s a forward and reverse switch. That’s right, shapers can be run in both directions. This isn’t something that you can do on a router table. When would you use this? The answer is actually “fairly often.” When cutting with some large profiles, it’s better to flip the cutter upside down, and trap the workpiece between the bit and the table. You can also squeeze out some extra life from rabbet cutters by flipping the cutter over, running it in reverse, and using the portion that’s usually below the table. It’s one of those things that you don’t know you need until you use it.

Beefier Construction

One of the most significant advantages of a shaper versus a router table is that they’re (generally) built a lot better. They’re geared towards a production shop, therefore a shaper has a lot of cast iron. They’re big, heavy, stable, and meant to run all day long. I don’t know how many times I’ve used a router table, and it feels like it will rattle apart as I work on it.

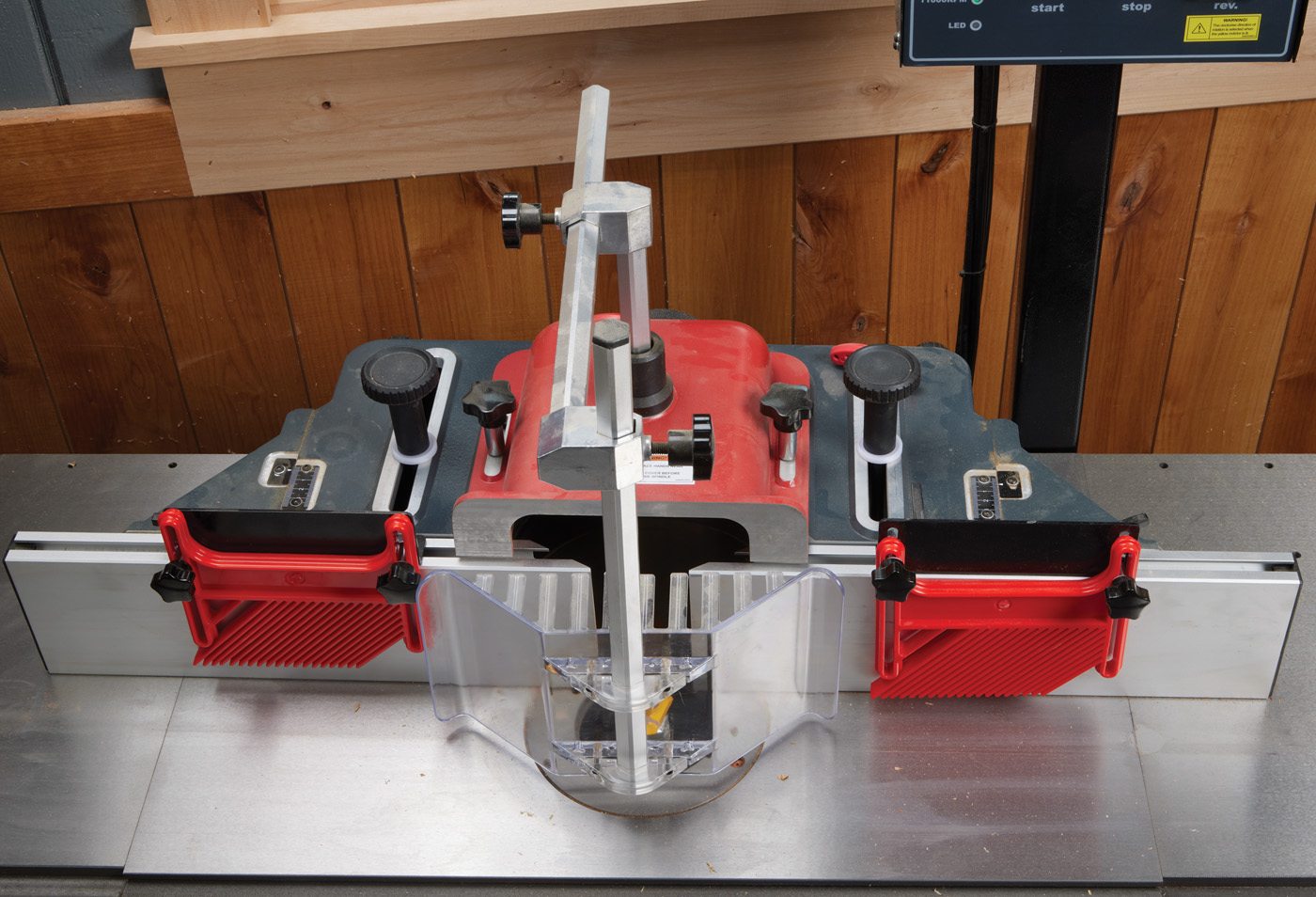

3 Shaper fences are generally more robust than standard home router table versions.

A good example of how heavily a shaper is built is shown in photo 4 below. The step pulley, spindle housing and motor are all built like a tank. This means that, even with the largest cutters installed, you can make full-depth passes without the smallest blip in the motor. Seriously, the motor doesn’t even know there’s wood there. Now, I’m basing much of my experience on my modern shaper. However, a lot of vintage shapers are available secondhand (for a very reasonable cost). Your mileage with those may vary from my experience with mine.

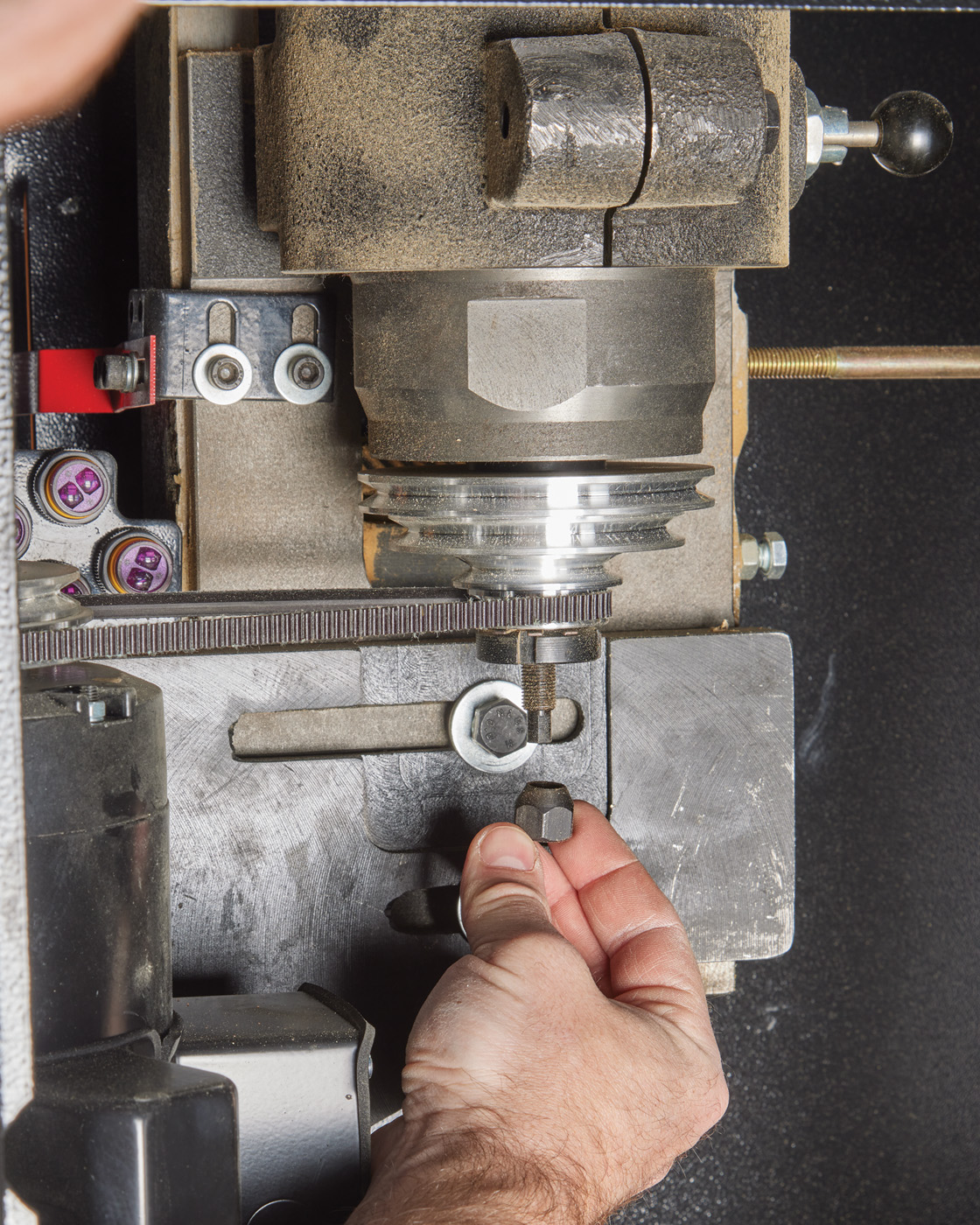

4 Spindles are held on via a drawbar. The internals of a shaper are built for production, and are cast iron.

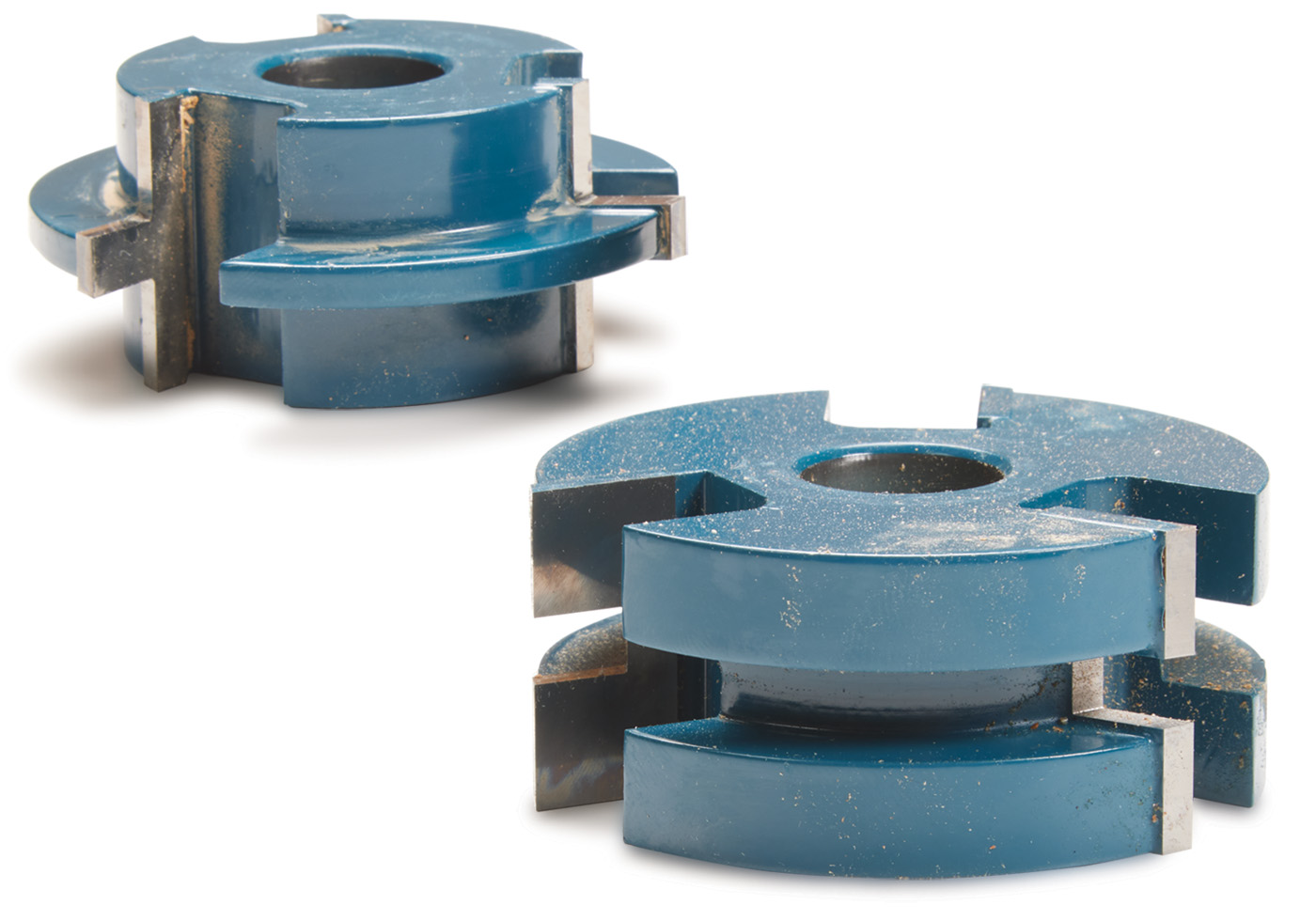

5 Shaper cutters are stacked on the spindle using a series of spacers.

Of course, there are a few downsides to shapers as well. The cutters can be more expensive (that’s all relative, as there are some costly router bits out there). With that said, there are many more options for cutters as well. About half a dozen bits cover 95% of what I do in my shop. I’ve listed those on the next page, including where I bought them from. They are more powerful, which means they’re usually 220/240v. But, if you have the power and the space for a shaper, I suggest you try one. I’ve found it’s much more valuable than a router table in my shop.

6 The mass of a shaper cutter combined with the torque of the motor make cutting buttery-smooth.

Essential Cutters

A. Tongue and groove bit. I use this for standard frame and panel assemblies. The Craftsman desk in the last issue? Almost all this bad-boy.

Woodline USA Tongue and Groove Shaper Cutter WL-1588 Shop Now

B. Rail and Stile door bit. These are used for creating cope and stick doors. The additional spacer (83-046) is used for exterior doors. These match with the ogee panel bit below for a traditional style raised panel door.

B. Rail and Stile door bit. These are used for creating cope and stick doors. The additional spacer (83-046) is used for exterior doors. These match with the ogee panel bit below for a traditional style raised panel door.

Infinity Tools Rail & Stile shaper 83-040 Shop Now (with 83-046 for exterior doors)

C. Ogee panel bit.

C. Ogee panel bit.

Infinity Tool Ogee panel bit 83-001 Shop Now

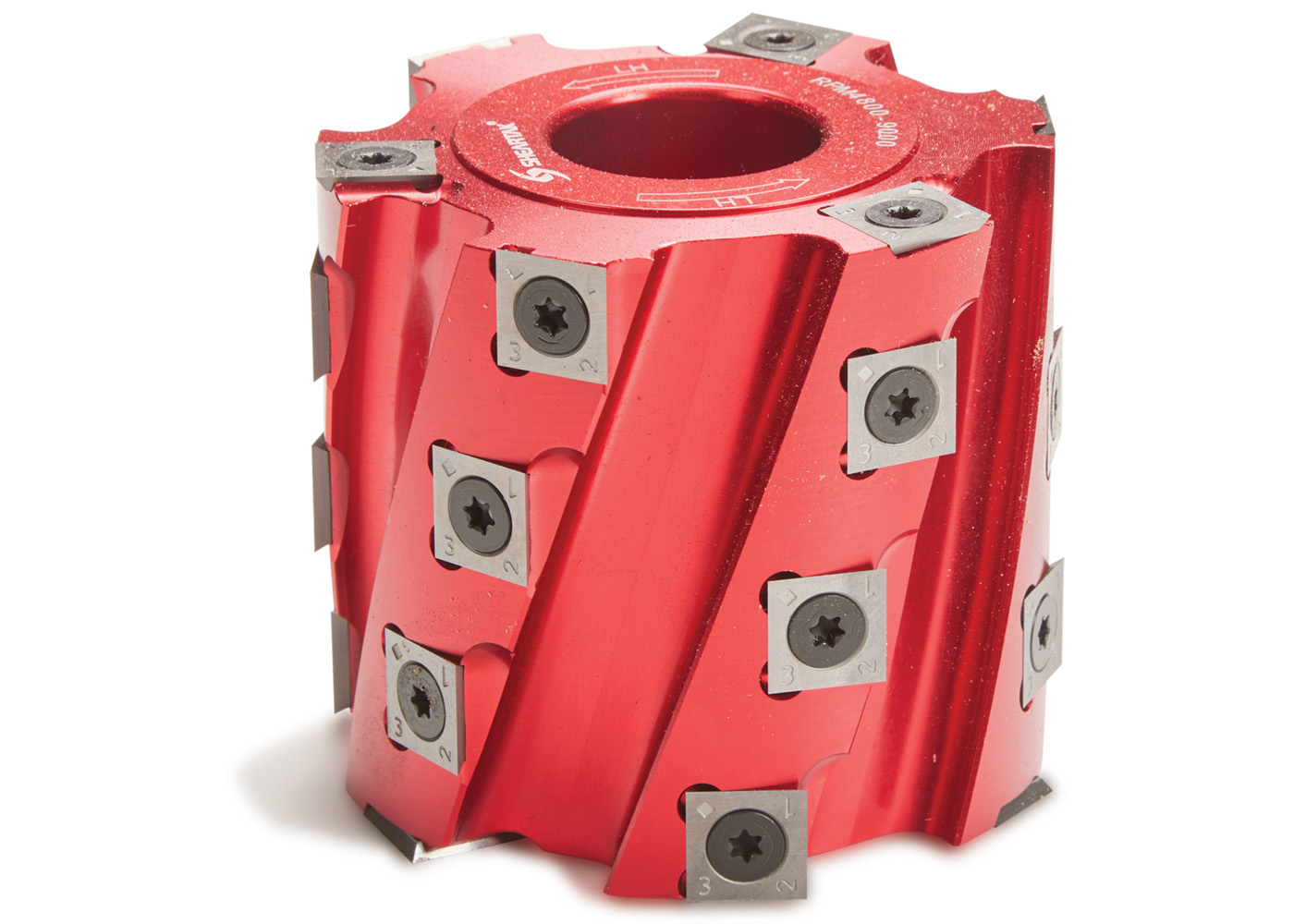

D. Jointing/Pattern cutter. This massive cutter is great for jointing operations on the shaper, or by adding a matching bearing, you can create a gigantic pattern bit for template shaping large parts.

ShearTak jointing/ pattern cutter 80204003 Shop Now

E. Wainscot Bit. Wainscoting or bead board is a great way to add detail to a back panel. This set makes it easy to run a batch all at once.

Woodline USA Wainscot WL-1598 Shop Now

F. Rabbet head. The addition of a few insert cutters on the top (and bottom) of this spiral head make it a great way to cut rabbets. If any head is “standardly loaded” into my shaper, it’s this one.