We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

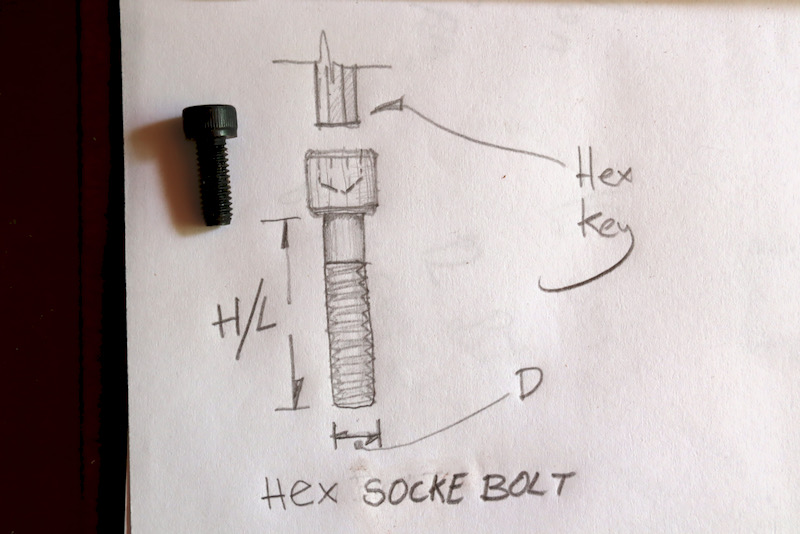

I own three bandsaws. Two are hand-me-downs from neighbors and the most recent arrival is a brand new Grizzly 17” that I bought. The Grizzly is a great machine but like many of its peers, most of the bandsaw adjustment features are controlled by locking socket head cap screw, aka Allen screws. There is nothing wrong with Allen screws, in fact, I prefer them to Philips screws and even slotted screws. But the reality is that every time I need to adjust something I have to negotiate with the Allen key that opens them. Many might not see this as an issue and would claim that the need for blade adjustment is not that high. But I find the use of the typical Allen key an inconvenience, so why not resolve this with an improvement?

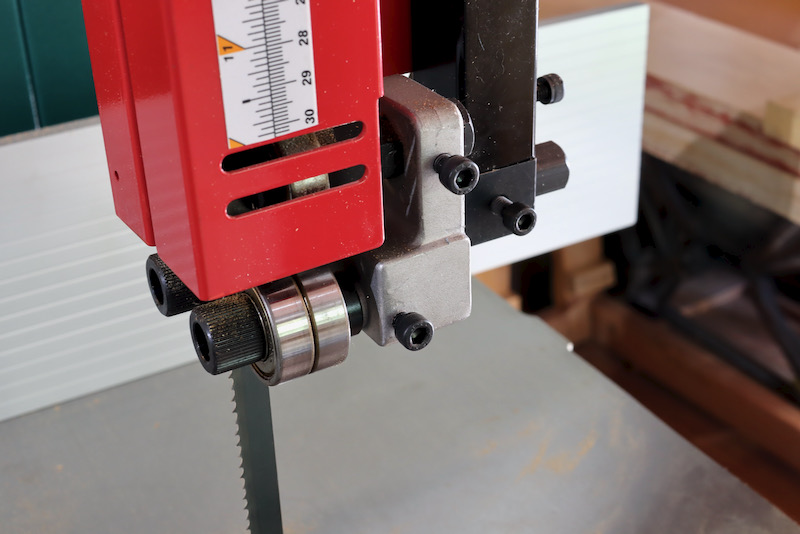

These are some of the original cap screws. A few others resided under the cast iron top and were even more awkward to engage. Luckily with the new thumb screws, all the necessary adjustments are now much easier to negotiate.

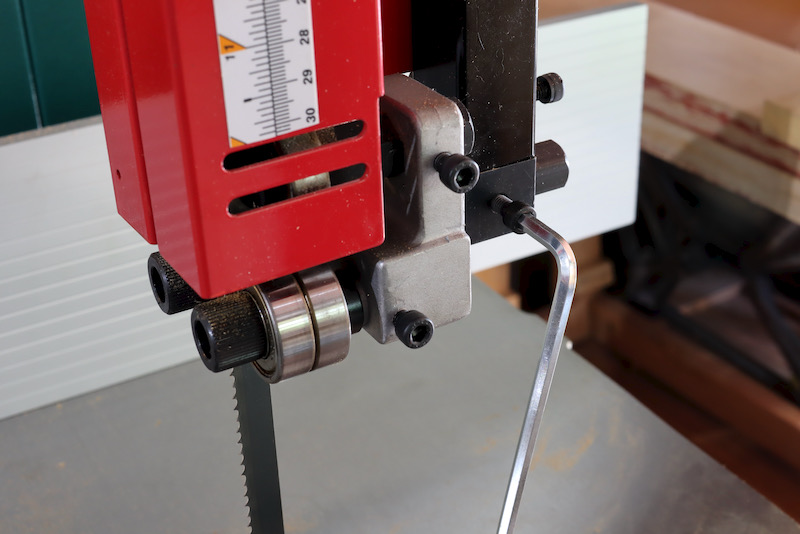

Even a T-handle Allen key is an improvement upon the regular “L” shape one.

Place a magnet on the saw’s frame to hang the needed keys on it. This minor improvement will save you time on the next occasion you’ll need to adjust your saw.

My solution to KIS (Key Irritation Syndrom) was buying some aftermarket thumb and adjustable handle screws. There are plenty of options out there, multiple designs, colors, handles, and screw materials to choose from.

The ones I decided to buy were the red-handled rotating knobs with a single wing (aka, adjustable thumb lever screw and threading rotating knob). These are very convenient thumbscrews that are perfect for locking the blade’s bearing rotation screws (or cool blocks in some bandsaws). The winged screws’ adjustable knob is spring-loaded, which allows it to be pulled out and repositioned into a more friendly angle. This feature is very important as it prevents the screw from becoming an obstacle to material that travels underneath it.

To reposition the wing just pull it out, rotate and let the spring pull it back to the desired angle.

I also decided to replace the Allen screws that tightens the guide blocks and lateral rod screw with more robust hardware. I chose an adjustable lever that allows me to produce additional torque on the mechanism.

Choosing The Right Screws

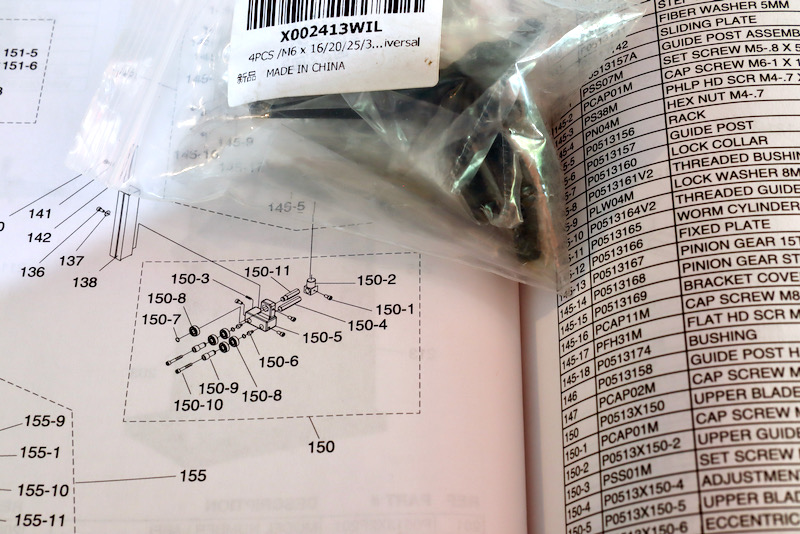

We have two options here: using the user’s manual to identify the schematics of the screws or measure them ourselves.

A good user’s manual will clearly provide the fastener’s specs. For instance, the Allen screws that tightened the bearing rotation screws were M6-1 x16mm (a coarse metric screw).

If you don’t have a manual you’ll have to identify the screw by yourself. Use a screw identification plate, etc to find the thread info, for instance, ¼-20 for (Imperial) or M6-1 (Metric). Then measure the screw’s length (or height). This dimension is measured from underneath the head to the bottom of the screw.

Now you have all the info to deploy your catalog or favorite search engine and find the knobs that will make you happy and liberate you from the key.

To learn more about the Grizzly 17″ saw that I own check out the video below. Much like the maker of the video, I too like this saw quite a lot.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.