We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

This tool is a carver’s dream, but it had to be saved from history first.

This tool is a carver’s dream, but it had to be saved from history first.

There is an unfortunate reality that many woodworking techniques and tools have been lost to time as traditions die out and technology advances. Wood, as a medium, is also often impermanent and susceptible to the elements. Research historians such as myself have to rely on the limited historic artifacts and artwork to understand medieval woodworking practices.

Online Extra: Learn how to make your own Scandinavian grind skew chisel.

More Scandinavian Woodworking: Scandinavian Workbench

Additional Reading: Everything You’ve Ever Wanted to Know About Chisels

One such artifact is the Tylldal chair, a 12th-century Norwegian artifact that was rediscovered in the late nineteenth century in a church in the village of Tylldal. The chair is an intricately-carved masterpiece that gives us a glimpse into the past, and has been a key part of my research.

1 The Tylldal chair is completely covered in complex and detailed carvings.

How I Research

While my academic background includes formal studies, my primary identity is that of a practitioner. My first major experience in this field was at the City & Guilds of London Art School, where I first reconstructed the Tylldal chair in 2019. That project showed me how overlooked medieval Scandinavian furniture is. I also uncovered the challenge of figuring out exactly what tools were used between the 11th and 13th centuries. Tool traces on original carvings have often been eroded through centuries of use, obscured by layers of later paint (as seen on the original Tylldal chair), or are too fragmentary to allow for definitive conclusions, even for the most experienced craftspeople.

Because of this, tool analysis is often based on the craftsperson’s skill and judgment. But this is where the act of making becomes important. By carving myself, I learned which techniques were easy or hard to do—and how that might have shaped how the original artist worked. This kind of knowledge adds a valuable layer to what we learn from books and artifacts.

Seeing the Chair Up Close

During my initial visit to the Historical Museum in Oslo in 2018—when the chair was still on display in the main medieval exhibition space—the conditions for research were far from ideal. I was not permitted to approach the chair closely, and the lighting in the exhibition area was poor. Time constraints and the immobility of the object further limited my ability to investigate. Only later did it become clear that the design elements of the chair were intrinsically linked to the historical choices of tools and materials.

Subsequent visits allowed me to examine the artifact up close and under proper lighting, enabling a level of detail that had previously been unattainable.

Learning from Practice

Through close observation of the tool marks on the original Tylldal chair, it became evident that a limited number of specialized tools were responsible for producing its characteristic ornamental features. Among these, one particular tool form stood out due to the distinct curvature and depth of the cuts observed. This prompted further investigation into historical sources—ranging from medieval illustrations and carved iconography to pre-industrial tool catalogues—in search of analogous implements.

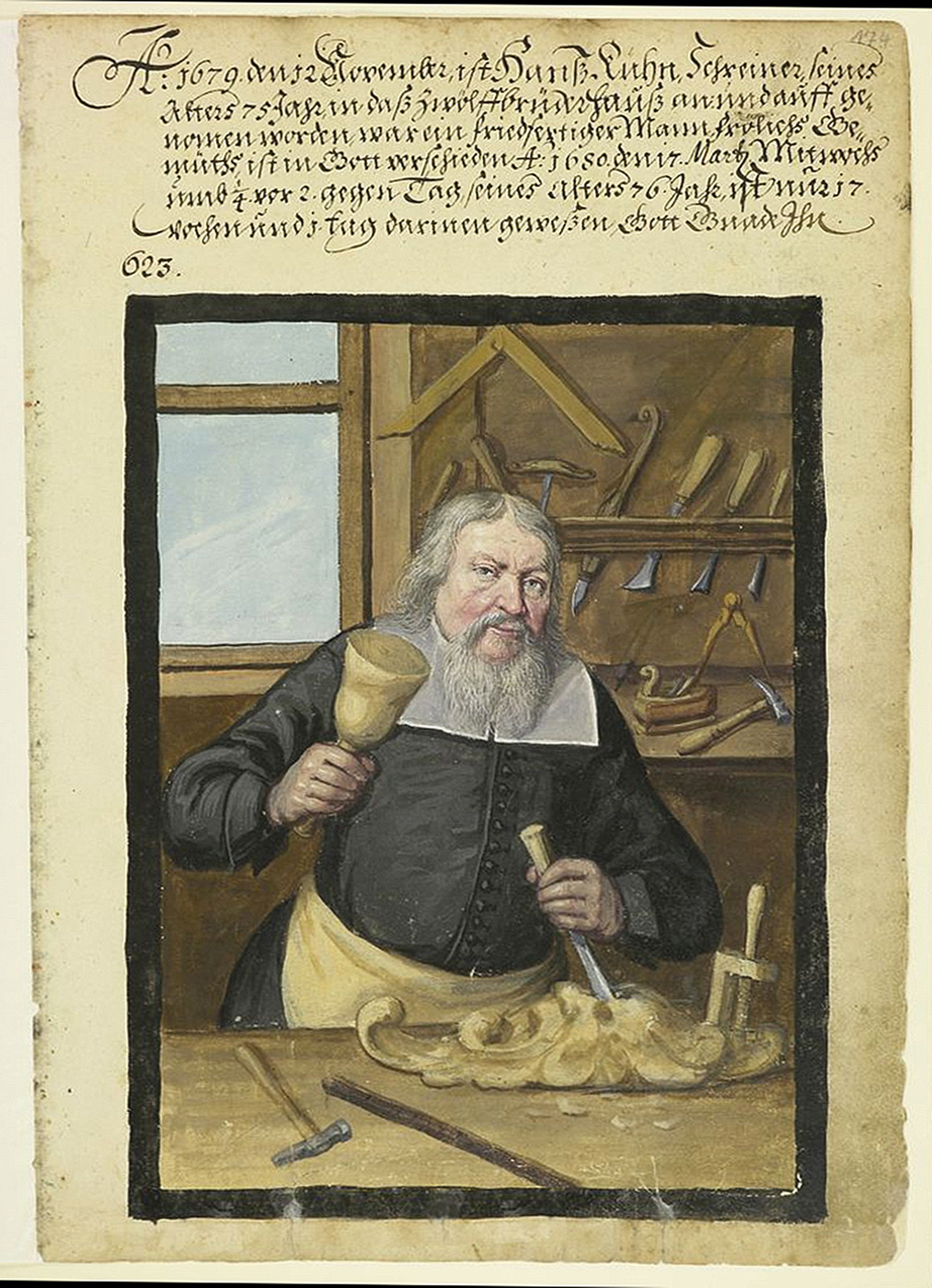

2 The form of this chisel is seen in contemporary art during the time it was being used. Here it appearers on the tool rack behind the craftsman.

The tool form most closely resembling one used in the ornamentation of the Tylldal chair has been identified in several of these sources. It bears a notable similarity to a skew chisel featuring a curved cutting edge, often described as having an “axe blade” profile.

There is ongoing debate regarding the historical specificity of this tool. Some argue that it represents a distinctly medieval type, while others suggest that the curved edge may simply reflect the users sharpening preference, resulting in a slightly convex edge line. Either way, it’s a tool that shows up again and again in my research.

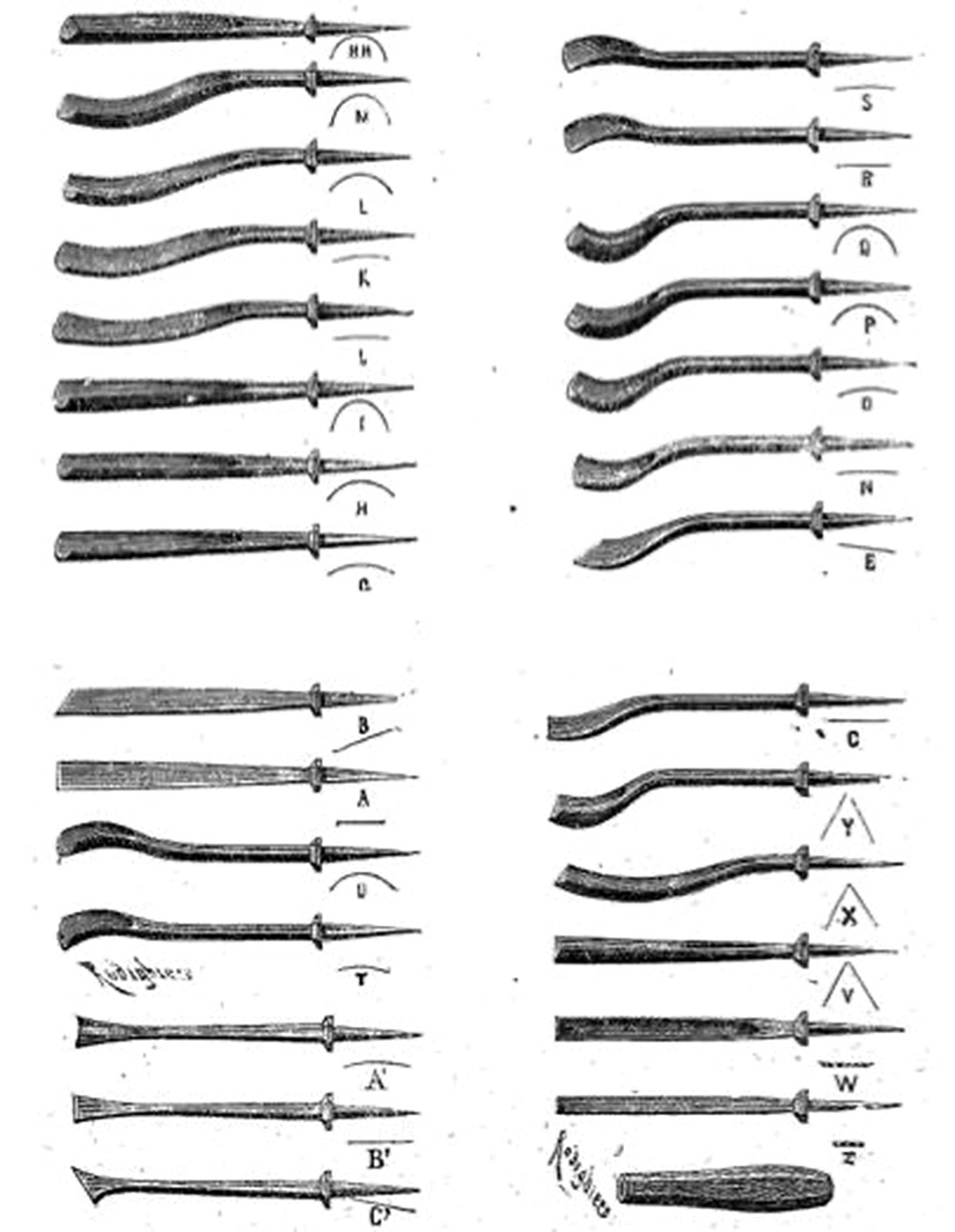

3 Historic catalogues offer key insights into the types of chisels the carvers would have used in their work.

In my own tests, I used a modern skew chisel made from high-carbon steel. While it’s not exactly the same as what medieval woodworkers used, it’s a useful approximation of the carving experience.

The distinctive curve of the blade and edge offers certain functional advantages—chief among them, the ability to execute freehanded, sweeping motions and produce fluid curved lines with greater ease than is possible using tools with a straight profile. Compared to a carving knife, the skew chisel—especially the medieval version—offers more control in some ways, but also has its own limits.

4 This smaller tool is part of a newer set I’m working with. It doesn’t feature the exact fishtail shape but it follows the same principles.

Testing The Chisel

Armed with my modified skew chisel and historic knowledge gleaned through research, it was time for some hands-on practice. The skew chisel with a Scandinavian grind produced a quality of line that was convincingly close to the historical example, albeit slightly stiffer in execution. When comparing the results of my replica to the original, the resemblance was striking. The incredibly fine engraved lines, likely the product of the thriving walrus tusk carving tradition in Trondheim, centered around the Nidaros Cathedral between the 11-12th century—commonly referred to as morsecarving, are a testament to the use of a skew chisel.

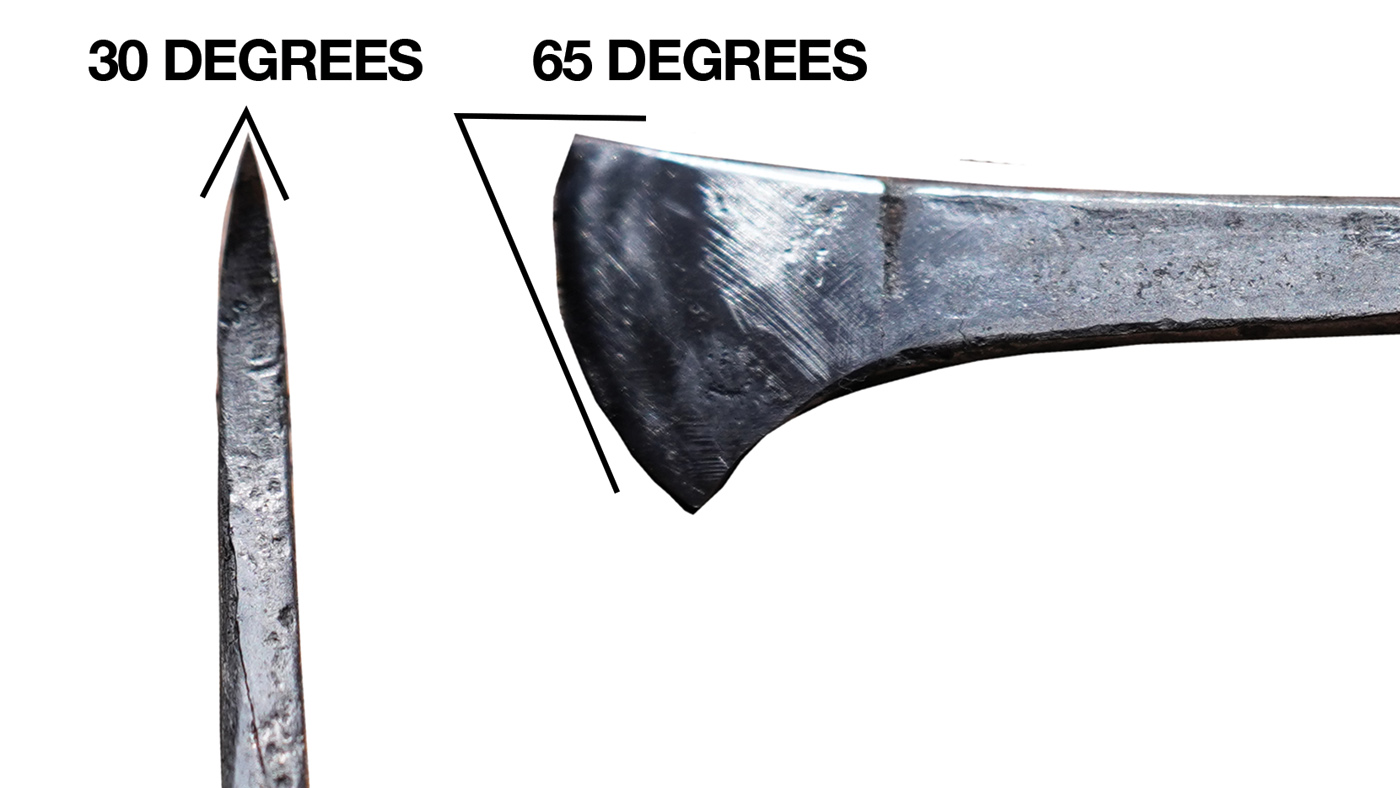

5 I usually aim for a bevel angle between 25–30°, and for fishtail shapes, I tend to ask for a flare that brings the cutting edge to around 1.5–2× the shaft width. The blade is usually at a 65° to the shaft, unlike the sharper hooked skew.

These fine lines, created using techniques closely related to kolrosing, appear to have been made with the same axe-shaped skew chisel. This single tool would have allowed for a range of operations—from incision and step-cuts to shaping and even miniature carving—making it a versatile instrument in the medieval craftsman’s toolkit.

The tool, when properly handled, operates more like a drawing instrument than a conventional chisel. It is guided with one hand holding the neck or head of the blade, while the other hand applies controlled downward pressure. This technique demands a reorientation, even from experienced carvers, but the outcome —as demonstrated by students in my courses—is a versatile workhorse for innumerable types of cuts.

Using A Skew Chisel

The Scandinavian grind skew chisel is a single tool that can undertake a wide variety of tasks. Instead of swapping between different implements, the user simply needs to reposition their hands to make entirely different types of cuts.

6 Drawing with the tip.

7 Drawing with the heel

8 Shaving with the tip

9 Gouging with the round shape of the blade

10 Sculpting with the blade

11 The chisel is capable of kolrosing, a Scandinavian technique that involves carving decorative, thin lines into wood.

12 In only twenty minutes, the carving begins to take shape.

13 Most of the chisels are custom-made by blacksmiths. This particular version was on loan from Norwegian Handicraft Institute. It is 22 mm wide, has a 25 mm long cutting edge, and the entire tool is 255 mm long including the handle.

14 Though incredibly versatile, the Scandinavian skew chisel is only part of larger compliment of tools a carver would have utilized.

15 A more finished example of the carving.

The curved cutting profile not only allows for this range of cuts, but it provides opportunity of grips as well, which helps maintain ergonomically sound body and hand positioning. It’s clear that the 12th century carvers who used this tool had a very diligent approach to their work, as it was their entire livelihood.