We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Your home center is a great source for workbench wood – once you figure out the pattern of how the lumber racks are replenished.

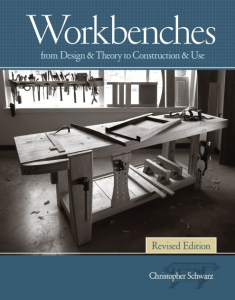

Looking for ways to save money when building your workbench? Here’s some great advice for saving on lumber for your bench. (Excerpted from “Workbenches: From Design & Theory to Construction & Use, Revised Edition” by Christopher Schwarz).

I use a lot of construction lumber in my projects – not only for workbenches but for furniture projects as well. If you carefully select your lumber you can end up with very nice wood for little money.

I don’t buy lumber for workbenches from a specialty lumberyard. I actually get it from my local home center. Here’s how I go about it.

Now as much as I like my local independent hardware store, I end up visiting my home center about twice a week for odds and ends. No matter how much of a hurry I’m in that day, my first stop is the framing lumber. I don’t always buy something, but I always watch the piles of 2 x 12s. And I look at the rack of lumber at the roof.

At my store, they usually have a Saturday-night cull. The employees pull all the junk from the racks that won’t sell because it’s too distorted or nasty. They band the culls and sell them for something real cheap. But I ignore the cull pile.

After they cull the racks they open up new bunks of fresh wood to replenish the racks that look skimpy. So Sunday morning is a great time to go to my home center.

I don’t go every Sunday, but I am usually rewarded with beautiful, straight and clear 2 x 12s. And if the bunk has been sitting at the top of the rack for months, the stuff will be dry – between 5 and 7 percent moisture content instead of the typical 15 to 20 percent.

—Christopher Schwarz

For more great ideas and advice for building your workbench check out “Workbenches: From Design & Theory to Construction & Use, Revised Edition” by Christopher Schwarz – available now at ShopWoodworking.com.

For more great ideas and advice for building your workbench check out “Workbenches: From Design & Theory to Construction & Use, Revised Edition” by Christopher Schwarz – available now at ShopWoodworking.com.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

Great advice. I hit the 4X4’s and the 2X12’s whenever I’m there.

Just this past Saturday I actually needed a 2X12 to make a stand for my mini lathe. All they had was crap. Leaning over in consternation, my hand landed on the 2X10 pile. The top boards were absolutely beautiful pieces of lumber. I brought home a 10 footer with just about 9 feet of clear as a bell wood. I’ll have to glue up the top to get the width, but PFFT, so the heck what!

No comment on the presence, or non-presence of similar boards in the garage rafters.

I recently built an 8 foot by 2 foot Roubo style workbench using southern yellow pine. My local home center ordered 2 x 12s that were 12 feet long in #1 grade for me to use. These boards yielded the material for the laminated top with enough left over to make legs and stringers, leg vise and other shorter parts. The lumber was dry and knot free. The boards were only $2 more than their stock #2 grade.

Local arborist in Denver,Mile High Tree care has dried slabs for sale, also, reclaimed boxcar recyclers

has oak beans and oak flowing from old railroad boxcars, How doe 6 by 9 by 10feet dried oak beams sounds for $150.00

There used to be a local lumber yard that struggled (till it folded) to keep parity in pricing with the Depot and Lowes. Their stacks of good stuff were always lovely and I used the same logic in picking through the tightest grain, scarce knots and the longest 2x12s I could find. Nowadays, I haunt the box stores for the same but after shuffling and refiling the racks, I still come up short on “good” stuff compared to the now shuttered local guy. Still, I keep looking…

Most of don’t build workbenches for a living so I recommend a way to get better but less expensive wood for your bench. Wood Mizer keeps a list of local sawyers where you can find local rough sawn wood for reasonable( most of the time) price points. Depending on where you live will determine what is available. If you have a tree that needs to come down that is also a possible resource when you call these ” have sawmill, will travel guys” who can come to your site and cut up some logs! At any rate, since most of us are only building an occasional bench you might want to make it out of some better wood. It might be your statement on your craft. Be mindful though that the harder the wood the more likely it will ding your work so look for a happy medium!