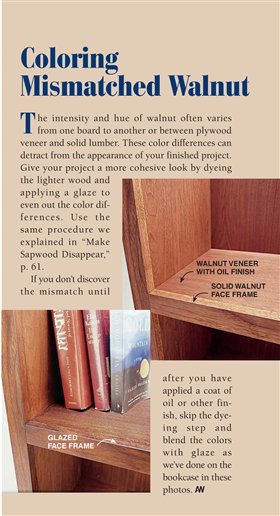

Make Sapwood Disappear

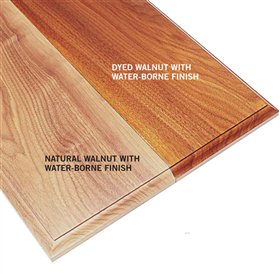

Even select walnut boards are likely to contain an

occasional streak of light-colored sapwood. Some projects

benefit from the contrast provided by skillfully

placed sapwood, but in most cases it’s merely a distraction.

If you can’t afford the luxury of avoiding all sapwood, we’ll show

you how to make it less conspicuous. Even though the initial investment

for dye, shellac and glaze materials will set you back about $100, most of these

products are highly concentrated and should last you many years.

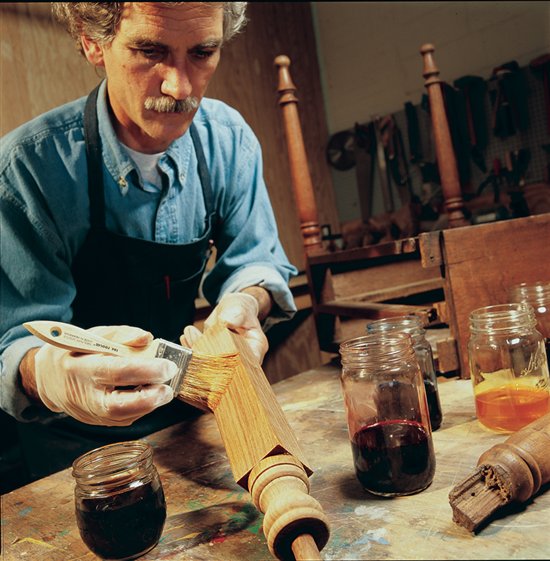

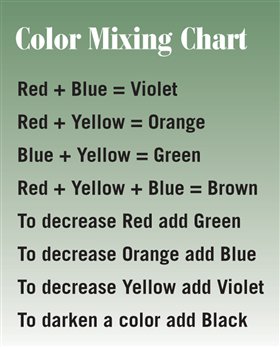

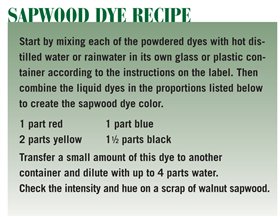

Dyeing sapwood looks paint-by-number simple but there are a few tricks. The key

to the process is getting the dye color to match the heartwood color. Don’t

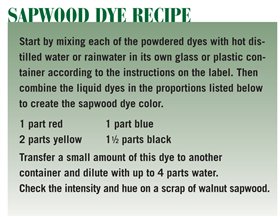

bother with dyes labeled “walnut.” Buy red, blue, yellow and black water-soluble

dye powder and custom mix a sapwood. We gradually adjusted the color of the dye by adding drops of

blue and black to reach the purplish gray hue of kiln-dried walnut.

An eye-dropper works great for this. Air-dried walnut has more

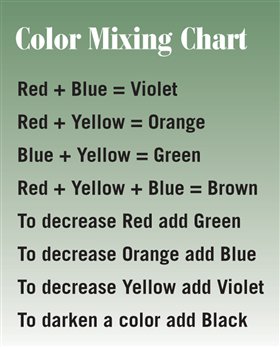

red. Adjust your dye accordingly using the Color Mixing Chart provided here as a guide.

We’re using water-soluble dye because it resists fading

in sunlight better than alcohol-soluble dye and is

easy to apply without leaving lap marks. One drawback,

however, is its tendency to raise wood grain. Minimize

grain raising by wetting the wood, letting it dry, and sanding

off the raised grain with 220-grit sandpaper before applying the dye.

Don’t sand too much or you’ll expose new

wood and negate the effect.

Here are a few more tips for working with watersoluble

dye:

– Wet the end grain before dyeing it to keep it from soaking up too

much dye.

– Start with a diluted dye; you can always increase the intensity of the

color by adding a “layer” of more concentrated dye.

– Adjust the color by adding another layer (refer to the Color Mixing

Chart). Wipe on green dye to decrease red, for example.

– The color you see when you apply the dye to the wood is close to

the color you’ll end up with. The wood will look dull when the dye dries,

but the “wet” color will return when the finish is applied.

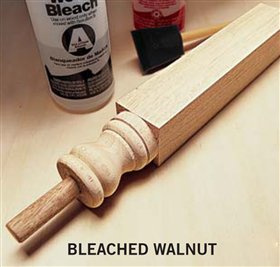

– Lighten dyed wood by wiping off some dye with a damp rag. If you

really goof, use household chlorine bleach to remove almost all of the dye.

Allow the dyed wood to dry completely, usually overnight. Then seal

the entire surface with a thin coat of brushed on shellac (about a 2-lb.

cut of super-blonde or other dewaxed shellac). Allow the sealer to dry

and sand it lightly with 320-grit sandpaper. If you’re happy with the way

the sapwood blends after the sealer is applied you can move on to applying

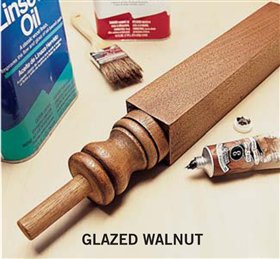

the final coats of finish. To blend the dyed sapwood more completely, and add greater depth and richer color, apply a thin layer

of glaze before applying the final coats of finish.

Glaze is essentially thinned paint that’s layered over a

sealed surface. Commercially prepared glazes are available,

or you can make your own. Mix up an oil glaze by

combining artist’s oil paint (available at art supply stores)

with a glazing medium consisting of three parts boiled linseed

oil, two parts mineral spirits and 1 part Japan drier, to

the consistency of heavy cream. We chose the “burnt

umber” color and it looked great. Pick up the following colors

as a starter set for blending your own custom colors;

burnt umber, raw umber, burnt sienna, raw sienna, Vandyke

brown, yellow ochre, black and blue.

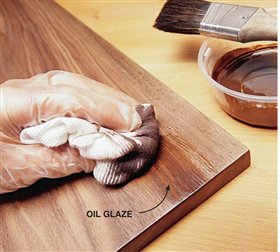

Complete the process of blending the sapwood by applying

a layer of glaze, as shown in Photo 2. Keep the brush

“dry” by removing

excess glaze from the

bristles with a rag. To

add glaze in one section,

“stipple” it on

with the tips of the

bristles and then

smooth it. If you

make a mistake,

remove the glaze

using a rag dampened

with mineral

spirits.

Allow the glaze to

dry completely, a minimum of 24 hours, before applying the

final coats of finish. Check by running your hand across the

surface. If glaze rubs off, it’s not dry. |

|

Click on any image to view a larger version.

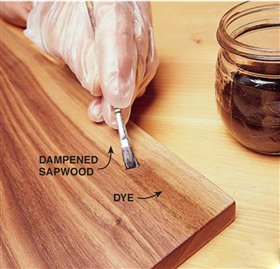

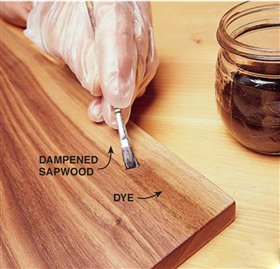

1. Use a small artist’s paint brush to carefully

dye the sapwood, following along the grain line.

Blend the edge of the dye into the heartwood with

the corner of a damp rag. Dampen the wood before

applying the dye.

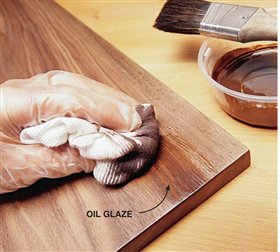

2. Apply the glaze with a rag or brush. Remove the excess,

leaving a thin layer.Then use a good-quality paint brush with

soft bristles to manipulate the glaze, adding or subtracting as

needed to blend the dyed sapwood into the heartwood.

|