We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Television Cabinet

Hide the electronics behind ingenious double-hinged doors

by Dave Munkittrick

I love my new 36-in. TV but my wife hates what the glass and plastic

monolith does to the look and feel of our family room. To avoid marital

strife we went looking for something to house the behemoth. No luck.

Sounds like a job for the family woodworker! I love it when I get a

chance to justify my sometimes-controversial investment in the shop.

A cabinet large enough to accommodate a 36-in. TV could look like an

oversized shipping crate. But I used a design with angled corners to

ease the big-box look.

Note: There are a few extra-deep 36-in. TVs that may require you to

cut a hole in the back for the TV to poke through. You could make a

deeper cabinet but you’d have to buy an additional sheet of plywood.

Play it safe; buy your TV first, then adjust the depth if necessary.

The double-hinged doors fold flat against the sides to open up the

cabinet for unobstructed viewing. Plus, they’re a whole lot cheaper and

easier to install than pocket doors. The adjustable, no- mortise,

partial-wrap hinges (see Sources, below) make these doors a snap to

hang.

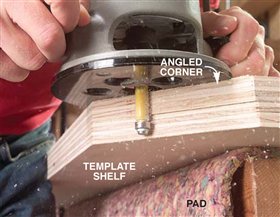

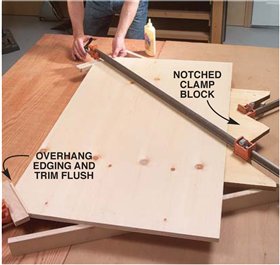

| 1. Make all the shelves identical by using one shelf as a template. Cut the angled corners on the other shelves a bit oversize. Clamp the rough-cut shelves to the template, and trim flush with a router. |

Click on any image to see a larger version. |

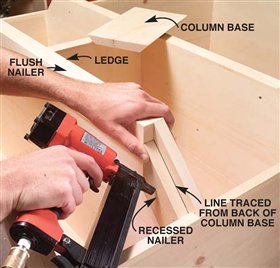

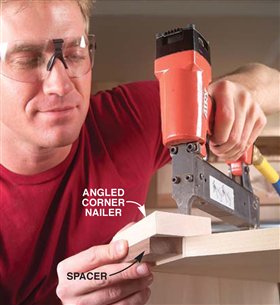

| 4. Create a ledge below the doors with solid wood fastened to the underside of the component shelf. Use a 7/8-in. spacer block to keep an even reveal. |

|

| 7. Attach the moldings with nails and glue. We used special molding glue instead of traditional yellow glue. The thick-bodied molding glue won’t drip or run while positioning the molding. |

|

| 9. Rout the ogee edge on the top. Just glue on the edging, sand flush and rout. Then screw the finished top onto the cabinet. |

|

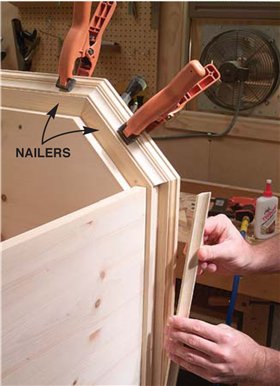

| 10. Apply cove molding under the top and against the edge of the nailers. Hold the molding in place with spring clamps as you go. Fasten the molding with glue and pin nails. |

|

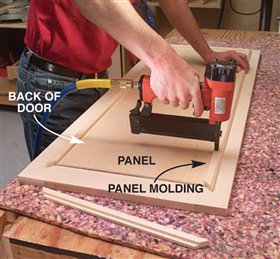

| 14. Nail panel molding to the back of the door frame to hold the 1/4-in. panel in place. Miter the corners of the molding to give your door a finished look inside and out. |

|

| 20. Screw the bun feet to the foot blocks. The thinner foot block in back allows the cabinet to sit level on a sagging floor. Sources(Source information may have changed since the original publication date.) Lee Valley & Veritas, leevalley.com, 800-871-8158, Two Iron Pendant Pulls, 01A60.30, $6 ea.; Two Iron Oval Pulls, 01A60.40, $7 ea.; Twelve Part Wrap Iron Hinges with Minaret Tips, 01H31.50, $4 ea.; One 18″ Black Full-Extension Drawer Slide, 02K11.18, $16 ea.; Four 3/8″ x 1/10″ Rare Earth Magnets, 99K32.03, $0.50 ea.; Public Lumber Company, publiclumber.com, 313-891-7125, Two 3/4″ birch plywood, $50 ea.; Two 3/4″ clear or knotty pine plywood, $70 ea.; One 1/4″ clear or knotty pine plywood, $40 ea.; 50 bd. ft. pine, $4 per bd. ft. Adams Wood Products, adamswoodproducts.com, 423-587-2942, Woodworker’s Supply, woodworker.com, 800-645-9292, One pint Titebond wood molding glue, 921-971, $7; One gal. sealcoat (shellac), 119-459, $23. Woodcraft, woodcraft.com, 800-225-1153, One Trans Tint Golden Brown Dye, 128482, $17. This story originally appeared in American Woodworker July 2003, issue #101. |

|

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.