We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

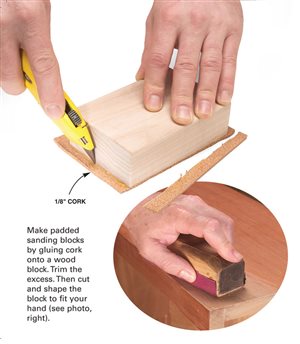

Shop-Made Sanding Blocks

Q:

Commercial sanding blocks all have some kind of padded bottom. Do my shop-made blocks need to be padded, too?

A:

Yes they do. Padded blocks have two primary benefits: They increase the life of your paper and they make it possible to use pressure-sensitive-adhesive (PSA) paper.

Cork is the easiest way to pad a shop-made sanding block. Cork is flat, firm and stiff enough to sand a plug flush or flatten a finish. The bit of give in a cork bottom provides some shock absorption for the individual grains of abrasive so they are not so easily knocked off the paper. This helps your sandpaper last longer.

It’s also much easier to remove PSA paper from a cork bottom than from bare wood. PSA paper can be cut exactly to fit your sanding block, so there’s no waste. Regular paper has to be cut oversize so you can hold the paper onto the block with your hand.

To make a padded sanding block, glue a piece of 1/8- or 1/4-in.- thick cork (available in hardware stores or home centers) onto the wood. Wood glue works fine as an adhesive; just be sure to keep the glue layer very thin because cork is porous and the glue can easily seep into it.

This story originally appeared in American Woodworker August 2006, issue #123.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.