We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

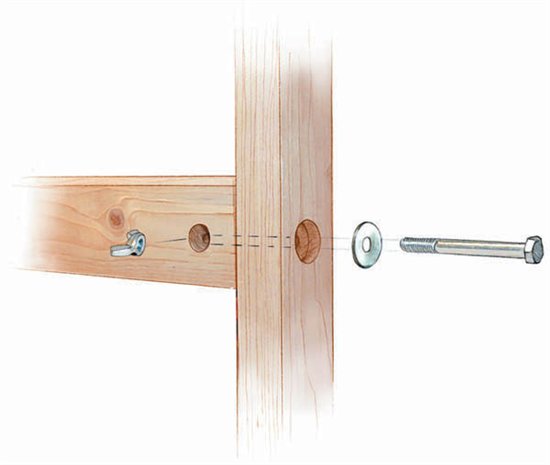

Workbench Joint

Plans for my knock-down workbench called for the 2 x 4 stretchers to be fastened with bolts and hex nuts. I'd have to rout huge pockets, weakening the stretcher, in order to get a wrench on the nuts. Yuck! I rummaged through my jelly jars of spare hardware and came up with this nifty solution.

First I counterbored a hole, large enough to fit my socket wrench, in the leg. Then I drilled a hole for a 3/8" bolt through the leg and into the stretcher. Finally, I drilled a 3/4" hole through the side of the stretcher. This hole is just big enough to slide in a 3/8" wing nut. When the bolt engages the wing nut, the wing nut jams against the sides of the hole. No more need for a wrench!

My Take

This is really a strong, useful joint. My guess is that after tightening and re-tightening the wing nuts, however, is that after a while, they'd no longer jam against the sides of the hole. Here's a better way: Cut lengths of copper tubing and tap them into the 3/4" holes in the stretcher. Drill the bolt hole through the copper tubing. Now, you've essentially got a washer inside the hole, so you can use a standard hex nut, and it'll bite into the copper. You could still use a wing nut if you wish. The point is that you've got a solid bearing surface for whatever nut you use.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.