We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Linker Logs Project

Have fun while learning to fabricate with plywood.

By Randy Johnson

Although linker logs are made with the aid of a computer—

once complete, they’re a great way to get kids (and

parents) off the computer for an afternoon of old-fashioned

fort building and pretend. The techniques shown here—

including pre-finishing the plywood, programming correct

joint tolerances, arranging parts, locating hold-downs and

placing tabs—can also be used for other plywood projects.

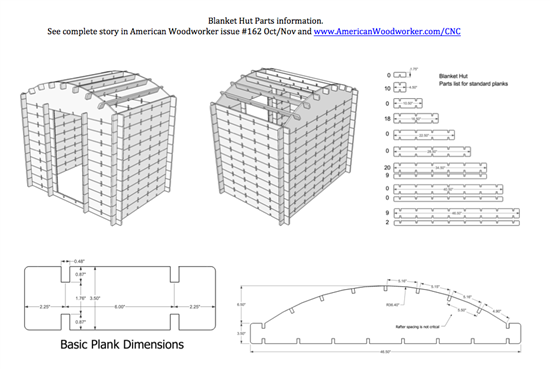

Th e inspiration for making these building planks comes

from a story titled “Plywood Play Planks” that appeared

in the December 1953 issue of Mechanix Illustrated magazine.

Th e original designers used 3/4″ plywood and a dado

blade to cut the joints. That technique can still be used,

but using a CNC provides more freedom when designing

the shape of the planks. Bill Young (a ShopBot guru from

Virginia) adapted the idea for the CNC by creating a wide

variety of planks, all with a standard notch spacing. The

playhouse shown below is similar to the original Mechanix

Illustrated design—but I added the puppet theater window

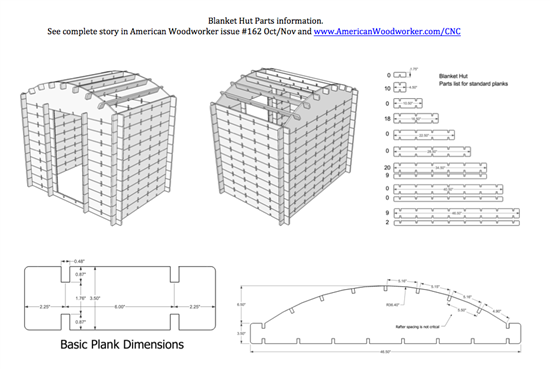

and marquee board. Also check out the Blanket Hut below, with with its custom barrel vault roof.

Start by finishing

A coat of shellac followed by a water-based topcoat provides

a durable finish for Linker Logs —and most other plywood

projects. Finishing a sheet of plywood is much easier than

finishing dozens of individual pieces, so applying the finish

first makes lots of sense. Shellac dries quickly and seals the

wood so the water-based topcoat won’t raise the grain, and

gives the plywood a nice amber tone. See “Pre-finishing

Plywood” (page 68) to learn more about finishing plywood. |

|

Click any image to view a larger version.

|

Measure the plywood

The thickness of the plywood must be consistent so the cross-lap

joints that fit properly. I recommend a tolerance between

sheets of plus or minus .005″. Most good-quality AC or AB

sanded plywood will be consistently sized. The sheets of 1/2″

plywood that I used to make this playhouse measured .47″ thick.

Measuring after applying the finish ensures the most accurate

measurement. |

|

|

Cut a single part to test the joint

Rout a test part. When you test the fit in the next step, the

width of the notch is the only thing that matters, so you can

make the test part out of almost anything. I used 1/2″ MDF.

The test notch measured .48″ wide, which should provide the

desired .01″ clearance when the cross-lap joint is assembled. |

|

|

Check the joint’s fit

A mechanic’s feeler gauge works well to measure the gap

between the parts of the cross-lap joint. Ideally, this gap will be

.01″, but anything from .005″ to .015″ is acceptable and will hold

the Linker Logs together while still allowing them to be easily

assembled and disassembled. |

|

|

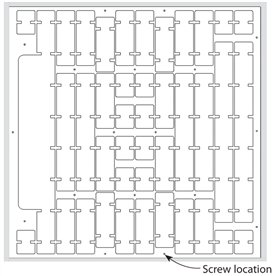

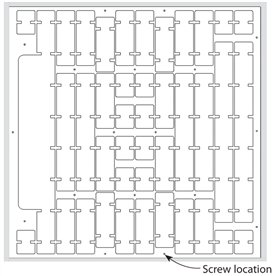

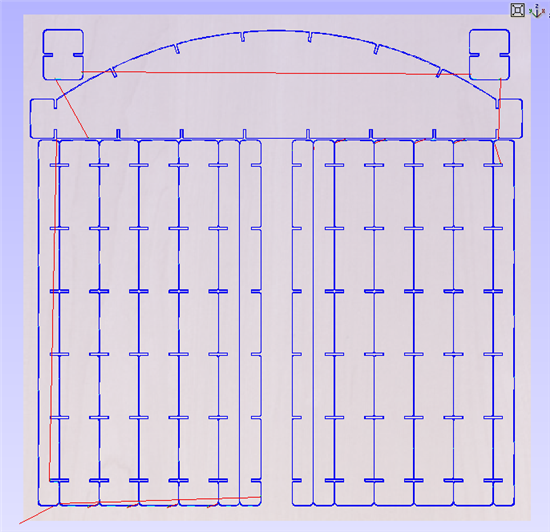

Nest parts and locate screws

Most CNC design programs include a “parts nesting” feature

that automatically fits multiple parts to the plywood. The Linker

Log parts shown here are nested .27″ inches apart—slightly

larger than the 1/4″ bit that will cut them out. Once the parts are

nested you can still move them around to attain the exact layout

you want. This allows you to safely locate the hold-down screws

that secure the plywood sheet.

PROJECT PLANS ARE AVAILABLE AT THE BOTTOM OF THIS PAGE. |

|

|

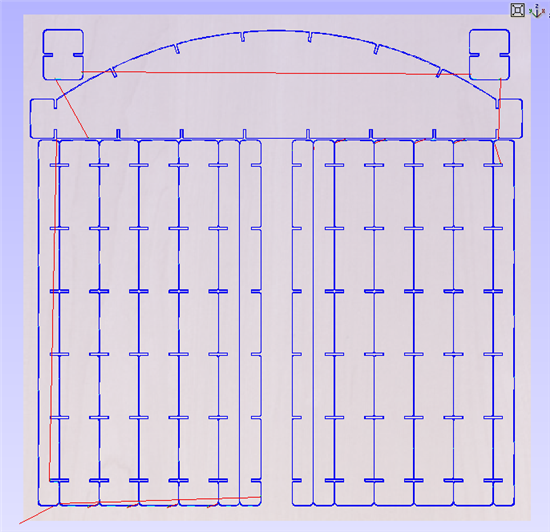

Add connecting tabs

The next step is to add tabs between the parts to keep them

attached during routing. Since there is no waste material

between most of the parts, tabs need to be added opposite

of each other. The tabs added here measure .1″ thick x 1″ long.

An alternative to adding tabs is to adjust the routing depth to

leave a thin layer of material (a skin) at the bottom of the kerf.

A skin of .05″ would work fine for this project. |

|

|

Secure the plywood with screws

Program the CNC to mark the location of each anchoring screw

with a shallow plunge cut. Locating the screws in your drawing

and transferring them to the plywood guarantees that the router

bit won’t run into the screws while cutting the parts. |

|

|

Use a down spiral bit

A down-cut spiral bit pushes the wood down while cutting,

so it leaves a nice, clean edge at the top of the plywood. The

bottom of the cut is also clean, because the spoil board under

the plywood prevents blow-out. |

|

|

Separate and roundover in one step

Remove the connecting tabs. A straight flush-trim bit

works well for this, but I used an Amana 1/8″ roundover

bit (#MR0112) with a miniature bearing. This bit removed

the tabs and rounded the sharp edges. It also allowed the

joints to fit fully together, because the logs’ rounded-over

edges match the rounded inside corners of their CNC-routed

notches. I left the edges and notches unfinished. |

|

|

Combo Puppet Theater and Play House

A combo puppet heater and play house that all kids seem

to enjoy, It features a marquee with room to engrave or paint your kid’s theater logo.

Project plans, Vectric Aspire, .dxf, and SketchUp files for the two playhouses can be downloaded at the bottom of this page.

Additional plank designs that included angles and curves

can be found at LinkerLogs.com. You supply the kids. |

|

|

Alternate T-bone notch

If you want to keep the plywood edges square, use a

“t-bone” notch design. Most CNC drawing programs

have a built-in tool that lets you quickly add the

right size “t-bone” to your joints. As you can see, this

modification lets the plywood fully seat in the bottom

of the notch. |

|

|

Download parts info (PDF)

Download Vectric Aspire, DXF files, and SketchUp files here. These are all in one zipped folder.

See more Linker Log ideas at www.LinkerLogs.com

| This story originally appeared in American Woodworker October/November 2012, issue #162.

|

|

DOWNLOAD STORY PDF

|

Product Recommendations

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.