For my job as a trim carpenter and furnituremaker,

I’ve always needed a sturdy stool to stand

on. I’ve also wanted to make a nice box for carrying

my tools and a small workbench for cutting molding.

While perched on an overturned bucket

one day, I thought, “Why not combine all three?”

The StepBox was born.

The StepBox has splayed sides for stability,

ample room for my tools, and grooves and notches in the top for

holding pieces of molding and drilling holes.

Building the StepBox gave me an opportunity

to learn how to make a challenging joint: the compound-

angle dovetail. While I could have merely

screwed the parts together, I wanted a stronger

joint. Dovetails are definitely the way to go. When

I stand on the stool, the joints actually tighten.

This project is built to last!

Materials

I made the base and handle of my

StepBox from 3/4″ hard maple. As

you know, this wood is very strong.

It can easily take my weight and

more when I stand on the stool.

Maple is also a good choice for

dovetailing. Pencil lines are easy to

see, and it cuts and pares cleanly,

without splintering. But because it’s

so hard, I have to keep my saw and

chisels extra-sharp.

I made the top from a 1″ thick

stair tread. It’s Southern yellow

pine—a tough wood, like maple,

but not as heavy. The top must withstand

a lot of wear and tear (I may

even drill into it occasionally), so I

used a piece of wood that would be

easy and inexpensive to replace.

The challenge

The StepBox’s base splays 12° in

both directions. It won’t tip over,

even when I stand with my feet right

on the edge. The splay also makes it

easier to fi sh out tools from the box

and drop them back inside.

Creating this splay is quite interesting:

You must cut the ends of all

four base pieces at a compound

angle. You might think that merely

mitering the pieces at 12° would do

the trick. It doesn’t. In order for all

four pieces to butt together, you

must bevel their ends at 2° as well.

These compound angles can

make your head spin. But you

won’t go wrong if you follow my

technique. Even so, I strongly suggest

that you make a complete base

from scrap wood first, to familiarize

yourself with each step, before cutting

into your expensive maple.

Cut the compound angles

Joint and plane the sides (B) and

ends (C) to final thickness. Crosscut

them about 1″ extra-long and

rip them about 1/4″ extra-wide.

Tilt the blade of your tablesaw to

12° and rip one long edge of each

piece. Flip each piece over and rip it

to final width (Photo 1). I clamped

a board to my fence so the bevel

didn’t get trapped under the fence.

Mark your pieces well. Stand

each board on edge, long side down, so you can clearly see which

way it leans. Think of the board as

one face of a pyramid with its top

cut off, as shown in Fig. A (below).

Using a carpenter’s pencil, write

Top—In and Top—Out in big, bold

letters on both sides of each piece.

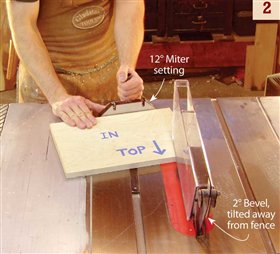

Get ready to make the first cut

on the end of each board. The procedure

to follow depends on which

way your sawblade tilts:

• For a left-tilt saw: Place your

miter gauge in the right-hand slot.

Rotate its head counterclockwise to

make a 12° cut (Photo 2). (Depending

on how your gauge is marked,

the reading will be 12° or 78°.) Tilt

the blade to 2°. Place each board

so the In side faces up and the Top

edge faces away from you. Cut the

end. Repeat this process for each

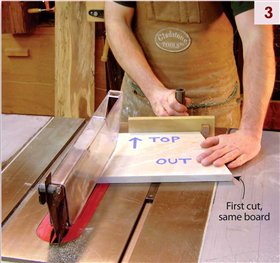

board. To cut the opposite ends,

move the miter gauge to the other

side of the blade (Photo 3). Fasten

a fence to the miter gauge, so you

can screw or clamp a stop block to

it. (You’ll need the stop block to

ensure that matching pieces are

cut the same length.) Flip over

each board so the Out side faces up

and the Top edge butts against the

miter gauge. Make the cuts.

• For a right-tilt saw: Place your

miter gauge in the right-hand slot.

Rotate its head clockwise to make

a 12° cut (the opposite direction

from the one shown in Photo 2).

Tilt the blade 2°. Place each board

so the Out side faces up and the Top

edge butts against the miter gauge.

Make the cut. For the second cut,

move the miter gauge to the lefthand

slot. Flip each board so the In

side faces up, and Top edge faces

away from you.

Cut the dovetails

If you thought the angles are tricky

so far, just wait! Laying out these

dovetails can make your eyes go

crossed—the angles just don’t look

right when you first draw them.

Fortunately, I used a foolproof system

for drawing the dovetails. Let me quickly

show you how it works, and then

we’ll move on.

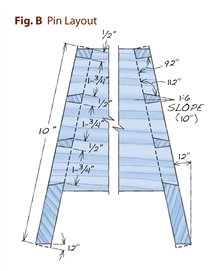

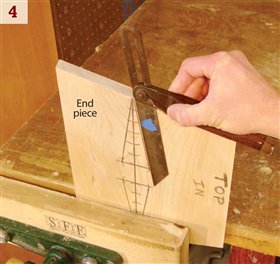

Lay out the pins first (Fig. B). Draw a pair of large triangles on the

inside face of each end board. The

long sides of the triangle represent

the pitch of the dovetails (in this

case, the familiar 1:6 ratio). Place

a sliding bevel on the face of the

board and set it to match the right

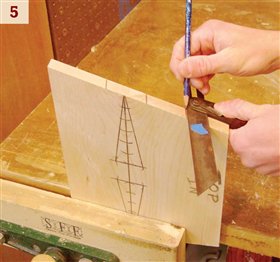

side of the triangle (Photo 4). Place

the square on the end of the board

and draw the right side of each pin

(Photo 5). Reset the sliding bevel to

the left side of the triangle to draw

the left side of each pin. That’s the

gist of it.

If you’ve made through dovetails

before, the rest is pretty standard. I

won’t claim it’s easy—just familiar.

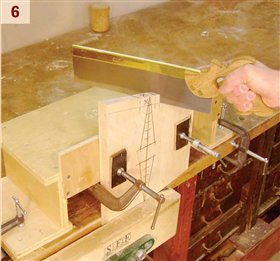

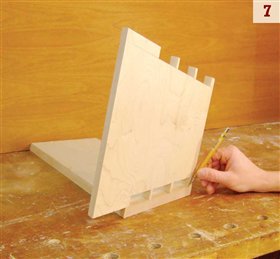

You saw and chop the pins (Photo 6),

then lay out, saw and chop the tails

(Photo 7). Accurate layout is the

key to the whole process.

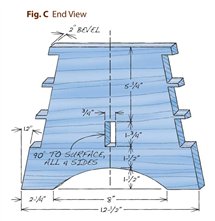

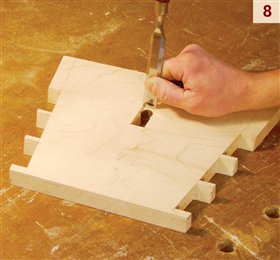

Mortises and arches

Before assembling the base, drill

and chop mortises for the handle

(D, Fig. C). Although the base has

a 12° splay, the top and bottom

walls of the mortises don’t lean at

12°—they’re square to the faces of

the end pieces. Use a pencil to lay

out the mortises on both sides of

each piece. Outline the perimeter

of the mortise with a knife or chisel.

Using a wide chisel, pare to

these scribed lines to establish a

shallow shoulder all the way around

the mortise. Do this on both the

front and back sides of the workpiece.

Use a 5/8″ Forstner bit in a

drill press to remove most of the

waste, then finish the mortise by

hand (Photo 8).

There’s one more task before

assembly: Cut arches on the bottom

side of both ends. The arches form

four feet. They give the stool more

stability on an uneven surface than

if the ends were left straight. Draw

the arches on the Out face of each

end piece. Tilt your bandsaw table

12° and cut the arches. Sand them

smooth. These surfaces should look

good, since they’ll face up when

you tote the StepBox around.

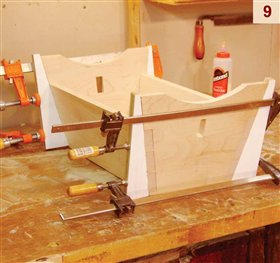

Glue the base

Make four gluing blocks, tapered

at 12° (Photo 9). It may be tempting

to use the offcuts from the base pieces, but their grain runs the

short way. They could easily crack

and break, and that would be really

bad news during a glue-up.

Make the blocks from a soft

wood, such as pine, with the grain

going the long way. Why use a soft

wood? If the pins stick out a bit,

they’ll crush into the wood, allowing

the block to continue pushing

against the tails—where you want

the pressure.

Glue a thick piece of paper onto

the face of each block. The paper

will absorb the glue squeeze-out

and prevent the blocks from adhering

to the base.

Glue and clamp the base. Plane,

scrape or sand the dovetails so

they’re flush.

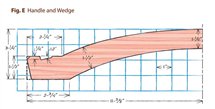

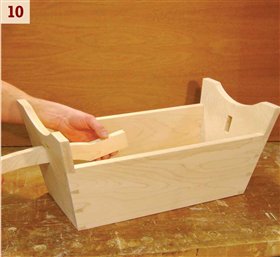

Make the handle

Saw out the handle (D, Fig. E), leaving

it 1″ or so extra-long on both

ends. (Note that the drawing shows

it cut to final length.) Don’t saw out

the notches on each end of the handle

yet—you’ll mark their locations

directly from the base.

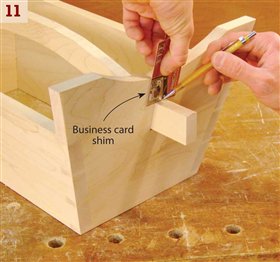

Slide the handle into the base

(Photo 10). Draw a line across the

top side of each end, using a business

card as a shim (Photo 11). This

shim deserves some explanation.

Let’s say you just drew the line for

each notch flush up against the

base. After cutting the notches,

you’d find that the distance

between them would be too short.

You have to allow the extra distance

caused by the splay of the base, and

that’s where the shim comes in.

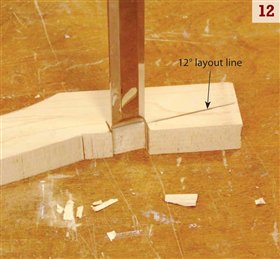

Withdraw the handle and saw

and chop the notches (Photo 12).

Stick the handle back in the base

and test the fit of the joints. Adjust

as necessary. When all is well,

remove the handle and round over

the section between the notches

with a spokeshave. Test how it feels in your hands, and make it rounder

or slimmer to suit.

Prepare two 12° wedges (E) for

locking in the handle. Make them

extra-long, so they’ll be easier to

make and install.

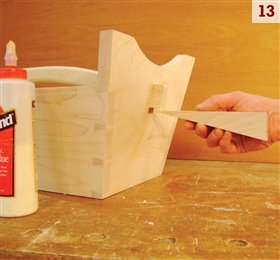

Brush glue on the handle’s

notches and slide the handle in

place. Apply glue to the wedges and

lightly tap them in place (Photo 13).

After the glue is dry, cut the handle

and wedges so they protrude 3/4″

beyond the end pieces. Soften their

edges with a file and sandpaper.

Add the top

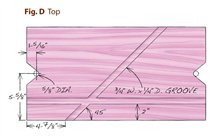

Cut the top (A) to final size. Cut

both grooves in the top using a

dado set in your tablesaw (Fig. D).

Use a miter gauge and fence for

making the 45° groove. To make

the notches, first drill a hole for

each one, then cut the notches on

the bandsaw.

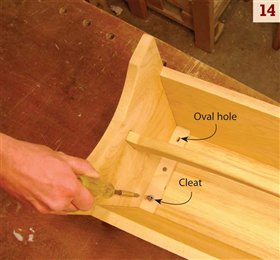

Make the cleats (F) that will be

used to fasten the top. Note that

the outer holes in the cleats are

oval (Fig. A). This allows the top to

shrink and swell without cracking.

Glue the cleats to the base.

Apply finish to the base and

top, then fasten the top to the base

(Photo 14).

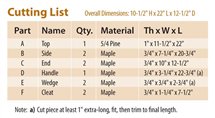

Cutting List

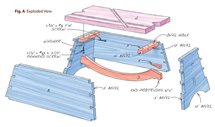

Fig. A: Exploded View

Fig. B: Pin Layout

Fig. C: End View

Fig. D: Top

Fig. E: Handle and Wedge

|

|

Click any image to view a larger version.

1. Rip 12° bevels on

the long edges of

the side and end

pieces. Note that

both edges are

beveled, and that

the bevels lean

the same way.

2. Saw an angled

end on each

piece. This is

a compound

cut: The miter

gauge is set at

12°; the blade is

tilted to 2°. (See

“Compound-

Angle Butt Joints”,

below.) The

inside surface of

the board must be

facing up.

3. Make the

second cut on

the other side of

the blade. Leave

the miter gauge

and blade at the

same settings,

but flip over the

workpiece, so the

outside surface is

facing up.

4. Lay out the

dovetails. Start

with the pins.

First, draw a

large triangle on

the board that

indicates the pitch

of the dovetails.

Set your sliding

bevel directly

from the triangle.

5. Transfer this

angle to the end

of the board. The

right side of the

triangle shows the

correct angle for

the right sides of

the pins.

6. Saw the pins.

This is a bit

trickier than

sawing standard

dovetails. Every

cut is a compound

angle—it leans

two ways. I use an

auxiliary support

to raise the

workpiece and

to keep it from

chattering.

7. Draw around

the pins to mark

the tails. Sawing

and chopping

out the tails is

no different than

making standard

tails, but once

again, these will

all be compound

angles.

8. Drill and chop

mortises for the

handle. There are

no compound

angles here—all

sides of the

mortise are square

to the surface.

9. Glue the base.

Use triangular

blocks to prevent

the clamps

from slipping or

digging into the

wood.

10. Insert a partially-sawn

handle into

one mortise, then

pass it on through

the second

mortise. The ends

of the handle are

cut extra-long for

now.

11. Draw a line

across each end

of the handle. This

line marks the

outside shoulder

of a notch you’ll

cut in the handle.

Use a shim behind

the pencil to

compensate for

the splay of the

end pieces. Pull

out the handle.

12. Saw and pare

the notches.

Slide the handle

back through the

mortises and see

if the notches fit

the ends. If all is

well, remove the

handle and round

its faces with a

spokeshave.

13. Glue the handle

to the base. Slide

in a large 12°

wedge to lock the

handle in place.

After the glue is

dry, saw the end

of the handle and

the wedge to final

length.

14. Attach the top.

It’s fastened

through cleats

that are glued

to the base. The

outside holes in

the cleats are oval,

to allow the top

to move without

cracking. |