We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Harvey Industries started as an OEM manufacturer. The company produced tools for various companies before breaking off to sell directly to the customer. This shift allows Harvey to tightly control quality, as well as quickly make changes to tools if they’re needed.

A Rare Look Into A Chinese Tool Manufacturer.

Recently, I received an invite for a rare opportunity — a chance to travel from the US to China to visit a Chinese tool manufacturer. From a personal standpoint, a trip like this appealed to me. I’m fascinated by the manufacturing process of tools, so of course I wanted to see how some of these tools are made. However, from an editorial standpoint, I thought it was a great opportunity to share this rare insight look with our audience, to hopefully help educate the community on this process.

Harvey Industries

Traveling to China is not an easy thing to do. The visa application process is lengthy, expensive, and you must have an invite from a business to be granted a visa. The company that I was to visit was Harvey Industries, manufacturers of the Harvey Woodworking tools, as well as Bridge City Tools. I’ve used Harvey equipment for years, and have several pieces of it in my shop.

1 Harvey’s corporate office as a fully decked out woodworking shop, where craftsmen put their machinery to the test.

Painting the Landscape

Now, before we start talking about the manufacturing, let’s paint the landscape a little bit. Myself and three others traveled from the United States to Nanjing, China where Harvey is located. Harvey helped arrange all of the flights, hotels, and travel while we were in China. It was a total of about 20 hours on a plane, and several more in airports.

When we arrived in China, I was amazed. I have been fortunate enough to travel much of the world, however I don’t think that I have ever been to a country that was as advanced as China is. As an American, I have a perception about China as well as Chinese manufacturing facilities. Words cannot explain to you how far from the truth each one of those stereotypes are. Traveling around the city, most of the cars are electric (signified by a green license plate). Let’s be clear — there are a lot of people in China (Nanjing has almost 10 million residents). With that said, it was one of the cleanest cities I have ever visited. It never felt overly crowded (proper infrastructure and such). The locals were some of the most humble and kindest people I’ve ever met. I won’t even touch on the food, but it’s safe to say that if I stayed much longer, I would have needed to buy bigger pants. Of course, this is a woodworking magazine, not a travel blog… so let’s talk about tools, shall we?

2 The Yangzhou factory serves as the assembly point for saws and lathes.

Facilities

Harvey’s headquarters is located in Nanjing with another location in Yangzhou. Nanjing has corporate offices, a show room, as well as a shop where a few craftsmen are using the Harvey tools (think of it as hands-on R&D). This is also where they assemble a lot of the Bridge City line, as well as the Gyro Air (dust collectors) and smaller accessory tools. The Yangzhou facility is larger, with multiple buildings and many of the saws and lathes are assembled there.

If you’re like me, you would expect that a tool manufacturing facility in China is going to a dark, dirty warehouse where there are hundreds of people being paid pennies on the dollar assembling tools. I can assure you, that’s not what is happening (at least, not at Harvey). The Harvey facilities would be just as at home in the middle of Brooklyn or LA as it is in China. It’s bright, modern, and clean. The production floor is so organized it’s almost like an operating room. Everything is neat and orderly.

3 Racks of parts have been assembled and are ready to be installed.

I do want to take a moment and point something out. Harvey has manufactured tools for a long time. Long before they sold tools under the Harvey brand, Jack Xu (the founder) manufactured for a lot of large tool companies. More than likely, you’ve owned a tool manufactured by Harvey. Jack’s desire to create high-quality tools is what led him to start selling direct.

With all of that said, I will point out that Harvey does not run any machining operations or cast any parts in house. Instead, they’ve built a massive network of suppliers over the decades and have trained their suppliers on what sort of quality they need to see from them. Their philosophy is — let each company do what they do well. They source motors from one vendor, because they’re the best quality motor. Another vendor supplies machined aluminum to Harvey’s specifications, etc. Instead, what the Harvey manufacturing team (over 100 people) are responsible for are designing tools (in house), doing quality checks, and assembling the tools for shipment.

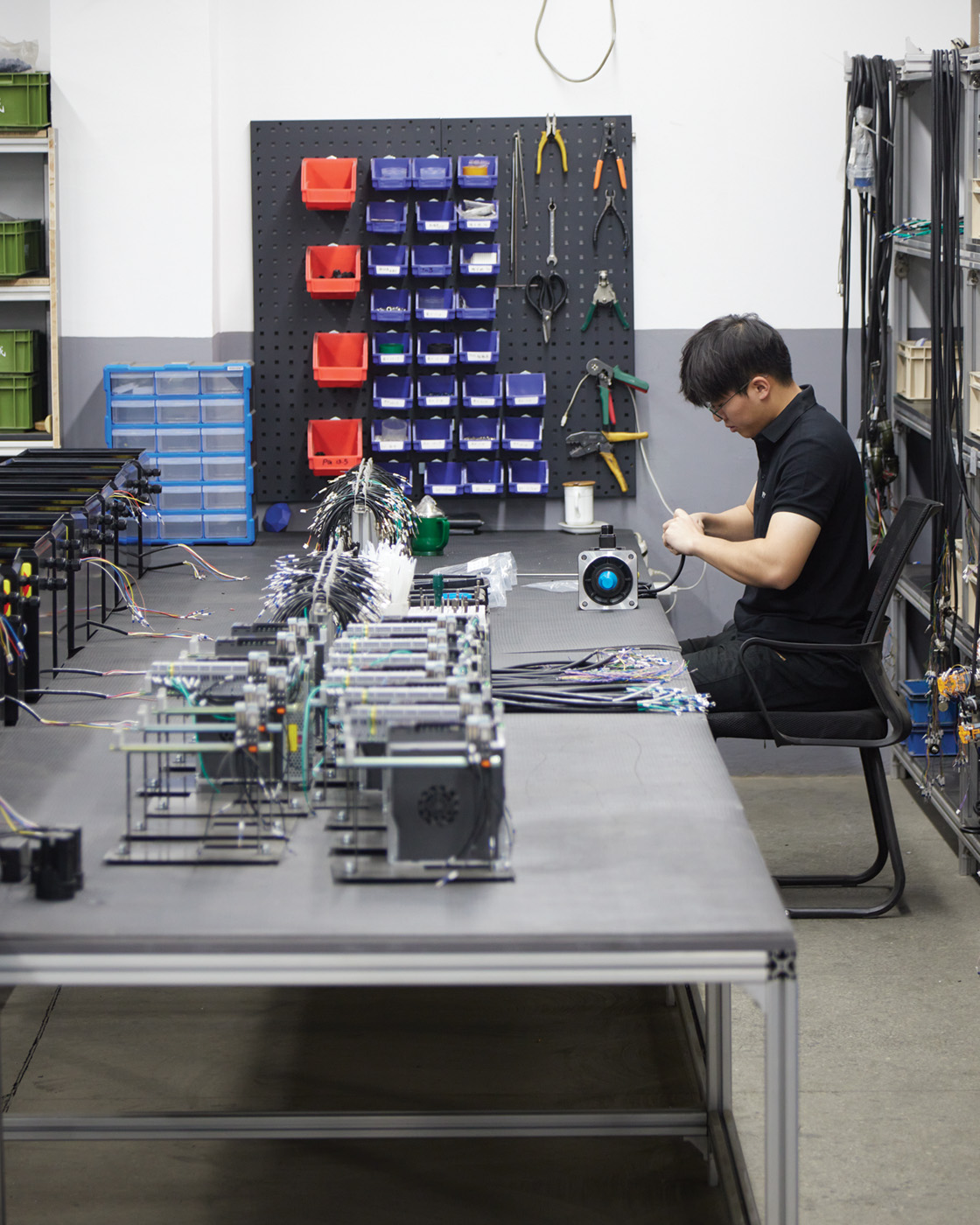

4 The production floor of Harvey has a variety of things going on. Some workers are assembling electrical components.

Production Employees

The Harvey staff that works the production floor are separated into (more or less) two groups. The assembly workers wear blue jackets or black polos. These are the men and women that are taking the parts from their suppliers and are assembling them into the tools that we receive on this end.

Others, are installing bandsaw wheels and making sure they’re coplanar.

6

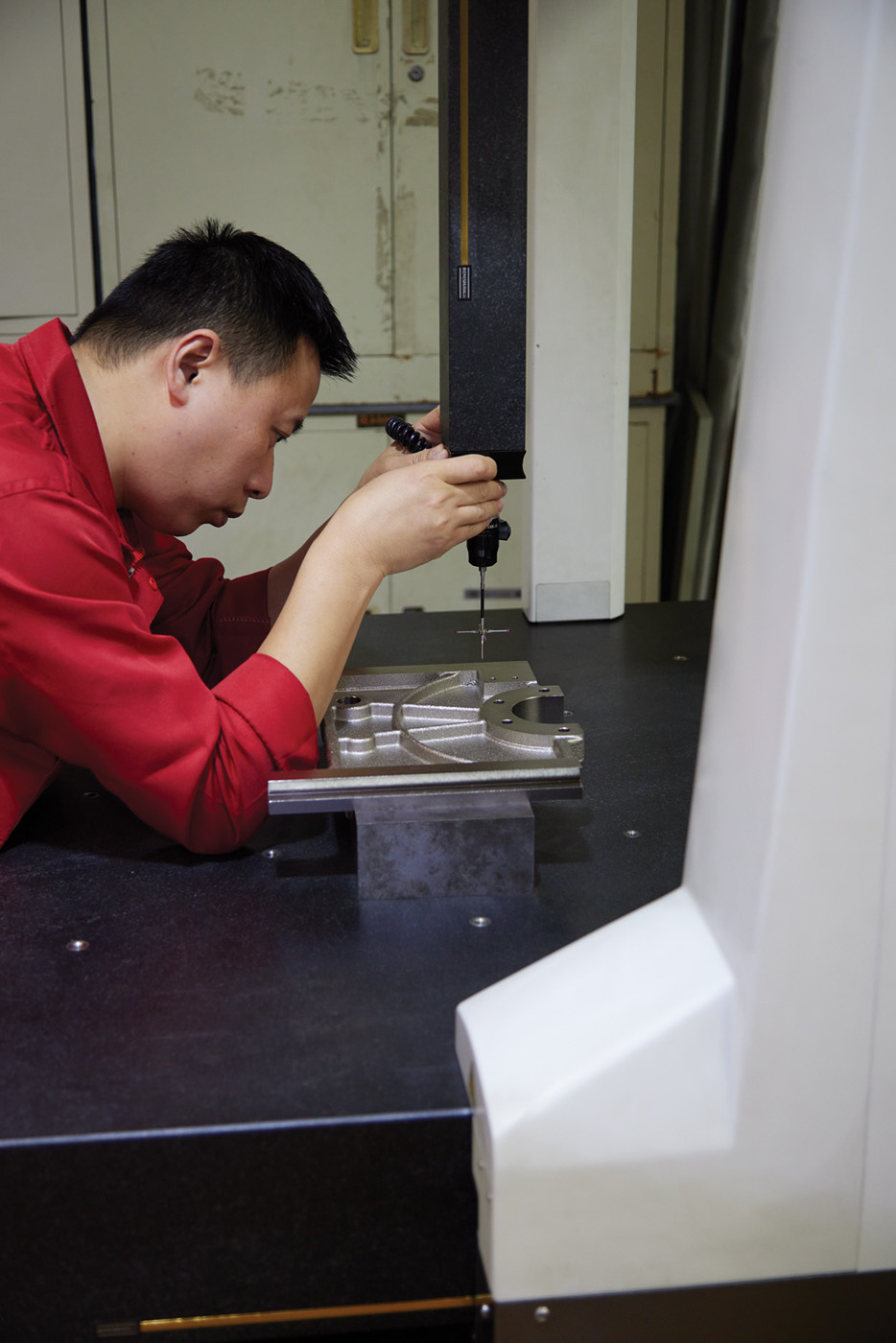

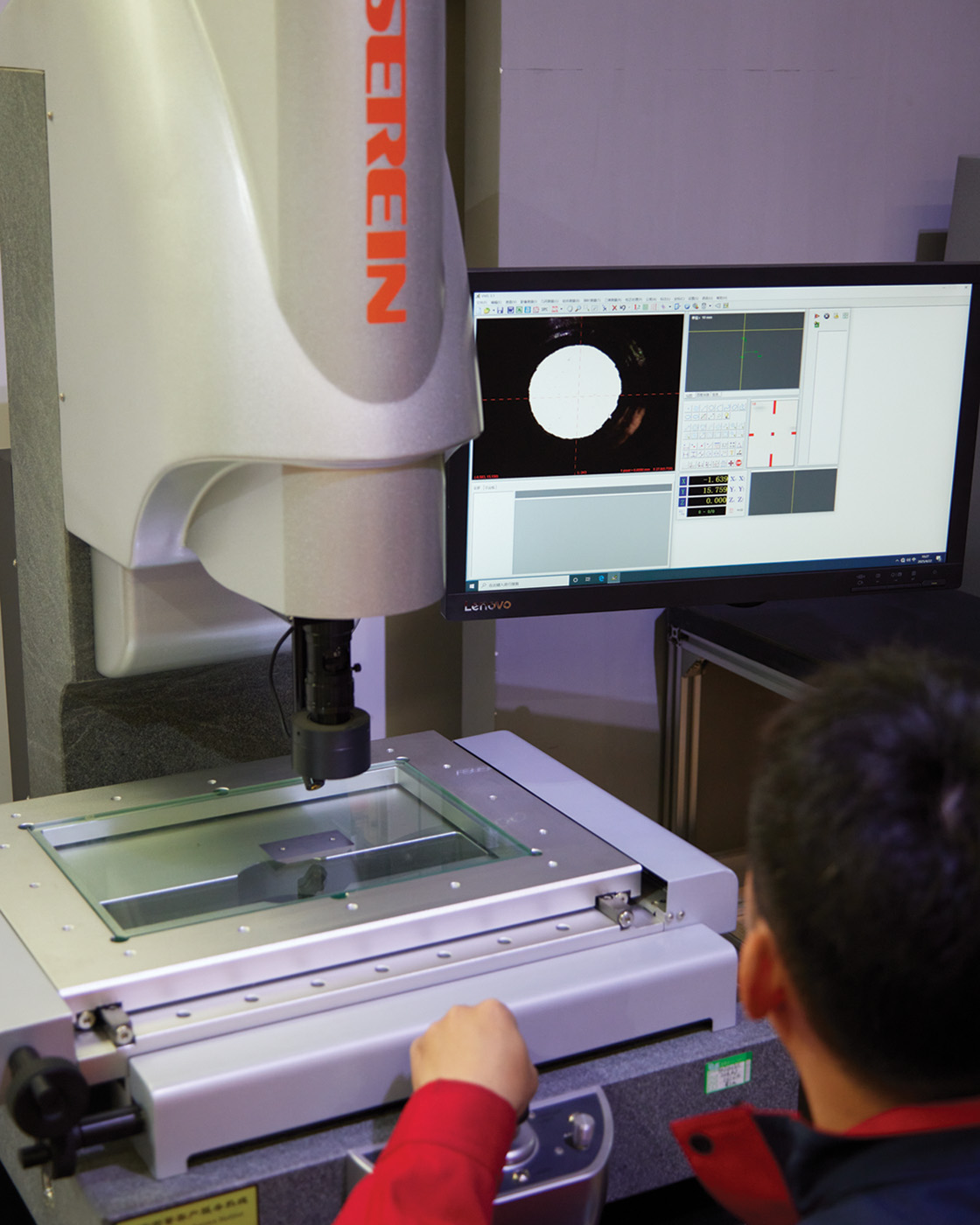

On the other end, we have the team members in red jackets. These are the quality inspectors. They are checking parts as they come in from suppliers to verify that they’re meeting the standards set forth by the company. You may think this is a simple visual inspection, but there’s actually an entire room set off to the side with ultra-high tech measuring equipment. Sapphire probes measure critical points on parts and the operators give them a pass or fail grade. I asked how often parts fail. The response was along the lines of “not much anymore, after we trained our suppliers.”

7 The Bridge City division has racks full of tools that have been assembled, and are ready for their final quality inspection before packing.

8

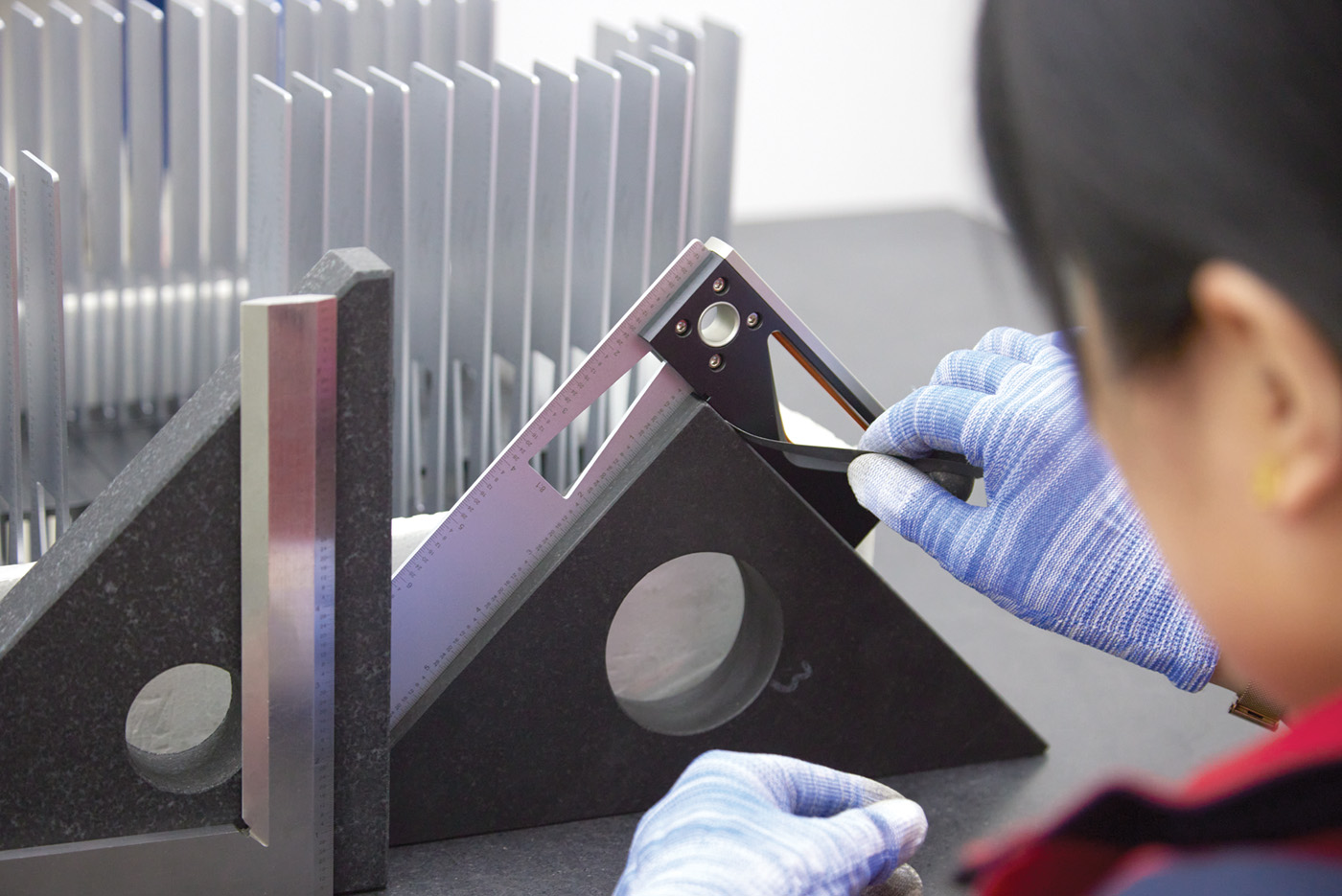

As long as the parts pass quality control, they’re passed off to the production employees for assembly. Each and every employee has a task, depending on what the operation for that day is. While we were there, the Big Eye Rip Fences were being assembled, and a large run of bandsaws was being assembled. At the end of the assembly process, each tool has passed quality control on the raw parts, several sets of hands that have assembled the tool, as well as another set to do final quality checks. The amount of feeler gauges being shoved and prodded in random locations on tools was amazing.

9 Each and every component is installed by hand and inspected.

10 Before parts hit the assembly floor, the quality team pulls samples and verifies quality standards using a variety of high-tech measuring devices.

11

12 Certain products, like squares, get probed with feeler gauges.

I think that is actually one of the biggest take aways that I have from this trip. The employees at Harvey truly take pride in their work, and are proud of the products that they produce. The ownership takes pride in paying his people well (they all own homes, and drive nice cars). The employees have a deep-rooted respect for the owner, and you can see that in their work.

13 All assembled tools get checked for setup before leaving.

14

Finally, I want to recognize one final point that I’m sure that I’ll hear about from our readers. Yes, I only was able to visit one manufacturer while I was in China. There may be instances of poor working conditions in other places. Harvey may be the anomaly. However, nothing I saw from the city nor the people would lead me to believe that.

15 Final signatures go with each piece of equipment before being packed in a shipping container and put on a boat.

16

The notion that any product that comes from overseas is low-quality is simply false. Cheap tools come from China. So do expensive ones. I think it all boils down to the motivation behind the company. Do they want to make a quality product, or make a buck?

If you want to hear a bit more about this trip to China, one of my travel companions has a video about it on his YouTube channel, @StumpyNubs.