We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Welcome to The Splinter Report, where I gather the assorted interesting and amusing things I’ve seen in the woodworking world. This week we’re looking at toys, first-time projects, and 15 great tips in 13 minutes.

Welcome to The Splinter Report, where I gather the assorted interesting and amusing things I’ve seen in the woodworking world. This week we’re looking at toys, first-time projects, and 15 great tips in 13 minutes.

Tool News Quick Bites

Festool Toys Arrive in the US: A while back, Festool released some incredibly realistic toy versions of their drill and track saw. They feature removable blades/bits, and even miniature Festool batteries that are interchangeable between all Festool toys. Those toys have finally made it over here, and while they aren’t cheap, they’re incredibly cool. So, pretty much exactly on brand.

Harbor Freight Stealth Drops New Band Saw: This is not breaking news at all, as the aforementioned saw seems to have come out in January, but I thought it warranted note. Harbor Freight finally retired their old 14″ Central Machinery band saw and have a new model under the Bauer name. It seems to be a variation of a similar saw sold under several other manufacturers, though at the traditional lower HF price. I took the opportunity last time I was in the store to poke around the saw a bit. While not in the same league as saws from Rikon or Powermatic, it seems to be well-built for the price point.

Local Oddity: My First Woodworking Project

In honor of Basics Week, I figured I would share the first woodworking project I designed myself. It was my senior year of shop class, and I was taking the advanced woodworking course at my high school (shout out to Mr. Ness!) The following year I would be attending college at the same school my cousin was going to, and when I had visited him that fall, I took measurements of the furniture inside his dorm room.

My goal was to make a shelf that would fit under the loft bed, with some shelves tall enough to hold textbooks, another the right height for CDs and DVDs, and it needed to be deep enough to fit a microwave. In short, a monstrosity. That being said, the final product looked ok from 10 feet, and seemed sufficiently robust in my 18-year-old eyes.

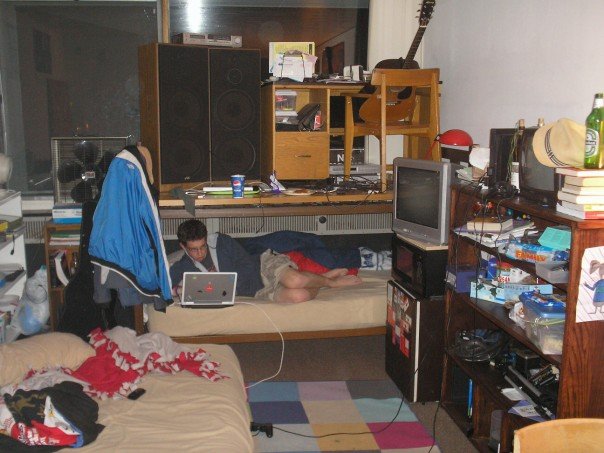

The shelf off to the right in this image. My roomate and I made some creative modifications to the room layout over the year, as you can clearly see. What you can’t see is that my room was on the 4th floor and the shelf didn’t fit in the elevator.

It turns out the robustness was more than sufficient. The shelf was made from 3/4 ply with rabbet joints and plenty of Titebond, and had an oak face frame. The shelf traveled with me when I transferred schools, from the dorm to three rental places in college (plus back home every summer), my first apartment, and my first house.

Here it is circa 2012

If I had to guess, I carried it up (and back down) at least 20 flights of stairs over the years. When I moved in 2o17, there was some serious thought to getting rid of it. It was never a very attractive shelf, and it was large and ungainly. Thankfully, I thought better of it, and pressed it into utility duty in the porch, where it still sits today.

Still as solid as ever.

There were questionable choices made with the face frame.

Out of Context Christopher Schwarz Quote

“So get beautiful by slathering on some dead cow creme.”

Video of the Week: Sticking the Landing

Were’re going to cross the finish line on-theme this week, with this helpful video from DIY Montreal. It starts with wood movement, a subject we didn’t even touch this week, and runs through 14 additional quick tips in just over 13 minutes.