We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

I’m not easily riled. But if you want to get me worked up, then make a casual comment on a piece of woodworking that you’ve never built or dealt with.

I’m not easily riled. But if you want to get me worked up, then make a casual comment on a piece of woodworking that you’ve never built or dealt with.

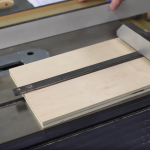

Case-in-point: I’ve been using a metal planing stop (as shown above) for more than 12 years. It is the foundation of everything I do at the bench. Yet, if I ever show its teeth in an article or on the internet, I know I’m going to get a comment such as this:

“You gonna cut yourself on that.”

I have never cut myself on my planing stop, just as I have never ever cut myself with a handsaw, chisel or handplane. My soft parts know to avoid the bitey bits. Your soft parts know the same thing, too (except for the soft part between your ears, apparently).

When I first started exploring traditional woodwork many years ago (I think I was 12 and tried to raise a panel with a block plane) I vowed not to bring my modern biases into play until I had built the vintage thing, used the vintage thing a lot and had the vintage thing figured out.

I know it’s tempting to try to “improve” something before you build it or have used it – it’s a natural response of the woodworker. But how do you know that the old thing needs to be improved if you’ve never used it? For me, the place to start is to build the vintage thing “to the print,” use it and then decide if it needs to be “improved.”

Usually, it doesn’t.

Take the metal planing stop for an example again. Many people told me I needed to cut a shallow mortise in the benchtop to conceal the teeth of the planing stop, even though I’ve never seen an historical example of this. Sure, it seemed like a reasonable idea. But before I went down that logical path, I simply built the planing stop as it is shown in hundreds of old texts.

The mortise to hide the teeth is unnecessary.

Why? Well I’m going to leave that to you to discover for yourself. You might think I’m full of crap. But until you make a metal planing stop for yourself and use it like millions of woodworkers who were born before you, you’ll never know.

— Christopher Schwarz

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

I’m with Jennie A. My 19th Century undertaker’s bench came with a bench stop that can be recessed to hide the teeth below the surface to allow laying something flat above it when the stop is not in use. Its height can also be adjusted for optimal positioning for various thicknesses of stock.

I don’t need to drive a car without seat belts to know it is an improvement on the original.

Just as adding the metal to the planning stop was an improvement on an all wooden one, so too can be the mortise in the bench or perhaps another idea.

The story of human history is improvement on the old.

My other hobby is shooting and I’ve taken a lot of classes. Same problem exists there. Folks cannot leave a factory firearm alone. Before they even use it, factory parts are being swapped out for relatively expensive aftermarket parts. Usually all this does is eat up money (that could be better spent on training) and taking a reliable firearm and making it unreliable.

Amen, Brother! Whatever works…

I guess I have taught about 300 post and rung chair green wood workers over the years. I suggest to them a shallow detent in front of the metal bench hook.

A gentle tap:

Clears the bench for large flat work.

Protects tools.

Protects hands.

I have never seen a period reference to a detent.

I don’ live there.

I have never has a problem.

I have never had an accident.

Do your thing.

I’ll do mine.

Mine is mortised in and screws up and down. Whatever shall I do now? I suppose if I come before the bench feeling…Schwarzy, I shan’t screw it down.

>>>>>>>>>>>>

When I first started exploring traditional woodwork many years ago (I think I was 12 and tried to raise a panel with a block plane) I vowed not to bring my modern biases into play until I had built the vintage thing, used the vintage thing a lot and had the vintage thing figured out.

I know it’s tempting to try to “improve” something before you build it or have used it – it’s a natural response of the woodworker. But how do you know that the old thing needs to be improved if you’ve never used it? For me, the place to start is to build the vintage thing “to the print,” use it and then decide if it needs to be “improved.”

>>>>>>>>>>>>

This sounds like the situation I encountered 20 years ago. I had a car that would not stay running and eventually would not start. It turned over just fine but for whatever reason, it would not fire up and when it did would die almost immediately. I had a co-worker, we’ll just call him poser. Poser had the annoying habit of asking me: “is it the alternator?”, I kid you not! The dude had absolutely no idea on the actual workings of the internal combustion engine, yet kept insisting on giving me, an individual that repaired his own autos, advice on how to fix it.

Unfortunately, there are a lot of individuals like that and I may or may not have been like that in my younger years. My long term memory is not as sharp as I’d like it to be. Yet, given the fact that I have this weird skill of looking at something for a while and seeing ways to improve and make it better, yet never being in a position to do anything about it; well, that’s just an annoyance I must always deal with.

Just as bad as those who want to throw away the old because it’s “so last century” are the ones that trumpet: “new and improved” and you find out that the new and improved may be new but, in addition to not being improved, it has less functionality and stability than the old. Being the compulsive perfectionist that I am, I prefer sticking with the tried and true old, rather than ending up with the new and improved that doesn’t do what you need to be done.

https://youtu.be/kOA2_PaXXns

Someone pushed that button just a bit too hard, Chris. It’s okay. MOST of us think you know more than we do about woodworking. That’s why we read your blog and your books.

“I’m not easily riled,”???

o K.

🙂

Great piece of kit but you’ll need to mortise it and mind your hands on the sharp stuff. Happy Christmas from England.

You fancy lads can discuss this crap; I have a floor to sand,trim to install, equipment to move, and a shop to design. I don’t give a shit about metal stops or wood ones; they both work fine. Tell me something I don’t know or just shut up!

I built my bench before I knew “the Schwarz” way of bench building. I moved the planing stop three times before settling on the spot it now inhabits. If I left the stop, as you do, above the surface, I’d have ruined many a project with it. That said, I agree with your “position” on the matter. It’s just that leaving the stop “proud” of the top would be STUPID on my bench.

That said, I must confess that I’ve been collecting iron bench stops for some time now. Most of them are in a drawer. The one I settled on, is an old Millers Falls design that allows me four different profiles for the business side. A quarter turn of the large inset fin and it locks into any position up to an inch a quarter above the bench surface. The opposite allows gravity to seat it back just below the surface. Voila!

I have the exact same stop and have used it for 5 years. At first, I left it proud. I did not cut myself or drag my plane over it. But it created an obstacle that prevented larger boards from resting flat. My shop is small and workbench space is precious to me, so the planing stop was often in the way. Of course, I removed the stop when I needed the flat space, and reinserted it when I needed it. Sometimes I had to remove and reinsert the planing stop every few minutes. This seemed inefficient.

One solution I considered was to make the stop’s tang a loose fit so it could be removed and reinserted quickly by hand. Another was to make the post a loose fit so it could be removed and reinserted quickly by hand. But a loose stop is an unstable stop, so I rejected these solutions.

A shallow notch in the benchtop now houses the teeth allowing me to lower the stop out of the way quickly with a single mallet strike. A mallet wack on the post’s tail under the workbench returns the stop to battery when duty calls. This modification saves me time and space.

You are happy with your stop as-is, and I would not presume to suggest my method is superior in any way. I don’t want to rile you, I just want to learn from your experience.

Does your planing stop never get in the way? Do you remove it when not using it?

I mortised mine because Raney mentioned that he cut himself on his. I am generally clumsy.

It’s also true that your experience isn’t necessarily the same as someone else’s experience.

I personally haven’t used a planing stop as shown because I KNOW that I will run over it with a plane blade eventually. I use brass dogs for similar reasons and I know how easily I forget that the dog can protude over the work. Call me careless if you like (it’s true), but having dealt with the relatively minor nicks caused by running over the brass dog I don’t want to find out how much of a mess I’ll make of it if I run over an iron stop.

Also, accidentally stabbed myself with chisels many times. I’m envious of your ability there 🙂

The metal planing stop freed me from having an end vise. For the things I build i’m very thankful for it.

Firstly, I’m very grateful for the knowledge you and all the contributors provide here and I’m a big fan of the books published. From my experience I tend to learn more about how I like to work the wood by exploring time tested methods. Very few modern approaches and contrivances bring me joy. My intoduction to woodworking at a young age included both vintage and modern methods. I have gone from using high tech machinery to falling in love with earlier beautifully monstrous machines and now for the past decade, sit amazed with human powered equipment. Although I have my preferred approach, I do not dismiss other ways to build. I’m not a production woodworker (been there, done that) so spending some more time to complete an operation or tune up a tool doesn’t bother me. I can sharpen for hours…meditation for me. Through my experiments with vintage things I have found they do not need improving, just a personal twist at times. A lot of folks seem to think their time is too vauable to waste on getting their hands dirty, yet seem to have no problem finding ample opportunity to share their rotten two cents. Please continue to share what you find, but don’t share too much…I like the challenge of figuring out the finer points. Thanks.

Hear hear….

Regards

Kaptain “If only I could have avoided my own silly incident with a Dozuki” Zero