We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Stable stance. Brace yourself against your bench when more stability is needed.

Get better woodworking results with these 12 tips.

I’ve been teaching now for more than 15 years. And in that time I’ve thought a lot about why students are or are not able to do certain things. Problems arise only rarely as a result of a student not having good information about how something should be done. Most know the steps involved. Many are familiar with multiple methods of cutting dovetails or mortise-and-tenon joints. The problems are almost always more fundamental in nature.

If you’re having trouble with your dovetails, or even your band sawing, here are a dozen fundamental things to think about that may help.

Stand up Straight? Actually, No

Woodworking is one example where standing up straight is actually a bad idea. Why? Standing up straight puts you in a position that is less balanced, less stable and less versatile than what you need for effective woodworking.

That doesn’t mean you should slouch. It’s just that good posture for woodworking is more like that for many sports. Woodworking is not really an athletic endeavor – although it can certainly have its moments. But when you’re trying to do almost anything physical, learning how to use your body better will definitely pay off. Not surprisingly, many of the basic principles from a variety of sports apply just as much to woodworking.

At left is the basic woodworking stance; brace yourself against your bench when more stability is needed (right).

What’s the better stance? Stand with your feet shoulder width apart, one foot pointing forward and the other pointing off somewhere between 45° and 90°. Your knees should be slightly bent, with your hips pushed gently forward. Many woodworkers will also lean against either the workbench or a machine for additional stability.

What’s better about this stance? It provides you a balanced, stable platform for all of your work. And when you’ve got that stability and balance, almost any woodworking task will be easier to control, whether it be planing, sawing, chiseling or even using one of your stationary machines. You’ll be able to extend your reach farther without losing your balance, and be able to use your strength and weight to greater advantage.

This certainly isn’t the only body position for woodworking, but it’s a really effective one.

Body Alignment

Alignment counts. Put your body in front of the saw (above) and you force your wrist and shoulder to move out of alignment with the tool in order to make a straight cut. Instead, align with the saw the parts of your body that are in motion (below).

Lining up your body properly will also help you to do the work more accurately and efficiently. The key to this is proper alignment.

Lining up your body properly will also help you to do the work more accurately and efficiently. The key to this is proper alignment.

For example, mis-alignment of your arms means you have to rely on multiple coordinated movements to control what you’re doing. It’s both less accurate and less powerful to add in this unnecessary or wasted movement. It’s not impossible to work this way, but it’s easier to just eliminate the extraneous movement.

When sawing, you should have your wrist and forearm lined up precisely with the back of the saw. This way, a simple, pivoting movement from your shoulder and some flexing at the elbow will move the saw in a straight line. If your wrist is flexed (your forearm doesn’t line up with the saw) and you’re standing in front of the board, your shoulder will have to twist and pivot, and your wrist has to bend and straighten (along with the elbow movement) to move the saw. This will be much harder (although not impossible) to control.

In addition to increasing your accuracy, aligning your body properly also means you’ll be putting less stress on the joints and fatiguing muscles less as well. You lessen the chance of a repetitive-stress injury.

Take Advantage of How Your Body Works

You also need to pay attention to the way your body naturally wants to move (also known as body mechanics). Take advantage of these natural tendencies and you’ll do better work. Work against them, and you’ll expend extra effort to overcome what your body naturally wants to do. For example, pulling a marking gauge toward you as you scribe a line takes advantage of the natural pivoting of your arm from the shoulder, and tends to tighten the gauge’s fence against the work as you pull. If you push the marking gauge, your arm wants to pivot away from the work. The same pivoting action affects your sanding. The natural tendency when sanding from side to side is to sand in arcs. It’s easier to sand straight with strokes that go out from and back toward your body.

Put Yourself (& the Wood) in the Right Place

Natural arc. The natural pivoting motion of the shoulder leads to a curved sandpaper path if you sand from side to side. For straight strokes, reposition the work (or yourself) to sand out from and back toward your body.

Setting your body up in a good position is more than just stance and alignment, however. You need to be in a good position to do the work. You also need to be able to see what needs to be seen. Getting these things right can be as simple as working at a good workbench. But that doesn’t take care of the problem if you fail to think about where you need to be in relation to the work. Don’t just put the workpiece on your bench a certain way because it’s easy to put it there. Ask yourself if you’ll be able to set up your body properly to do the work and to see important lines or relationships at the same time. You won’t be able to work effectively if your body position or alignment are thrown off by a poor choice in locating your work. And you can’t chop, pare or saw square if you can’t see what square is. A good bench allows for flexibility in securing your work for just this reason.

The right working height. A Moxon-style vise (this one is from Benchcrafted) can hold boards for dovetailing (and other work) at the perfect height.

When you finish one task and start to do something different, don’t just leave the work where it was if that position is no longer effective. Think about the best position for what you’re about to do. This may mean moving the work, or moving yourself.

I’m also a firm believer in raising or lowering the work as necessary, rather than simply hunching up your shoulders or bending over and straining your back. You’re better off adjusting the work to suit the best body position instead of contorting yourself to accommodate the work.

Separate Force & Control

Balanced pressure. You can plane a convex curve with a straight plane – you just have to learn to balance the pressure on the tool between your hands.

Most woodworking involves pushing or pulling either a tool or the wood in a controlled way. In most cases it helps to think about force behind the movement and the control over the tool or the wood as separate issues. One part of your body should be responsible for the push or pull (the force), and another for the precise control. So you may be controlling a chisel’s position with your hands and arms and possibly your shoulders, and applying force with shoulders, your core or your legs. Or you’ll subtly adjust the pressure on the front and back of a handplane with your hands and arms while pushing the plane forward with your lower body.

The same concept applies when you hold a board against the rip fence and down on the surface of the table saw with your left hand as you push the board through with your right hand. And also when you have to hold a tool at a constant angle for freehand sharpening.

Separation of force and control usually means you’re working more efficiently as well. Your lower body muscles are also much stronger than your upper body ones. And relying on the stronger muscles to do the harder work makes sense.

In reality, some of the work inevitably gets done by your other hand or other part of the body. But thinking about the separation of chores this way will definitely help you to gain more control over your actions.

Stay Contained

You have more power and more accuracy close to your body. So if you’re looking to increase one or both of these, you need to keep things close – though not so close that you’re cramping your ability to work (but it might be closer than you think). Most of the time, your elbows shouldn’t stray too far from your torso. Even handplaning is best with your elbows close to your body – no more than a foot away from your hips most of the time.

Stop Working so Hard

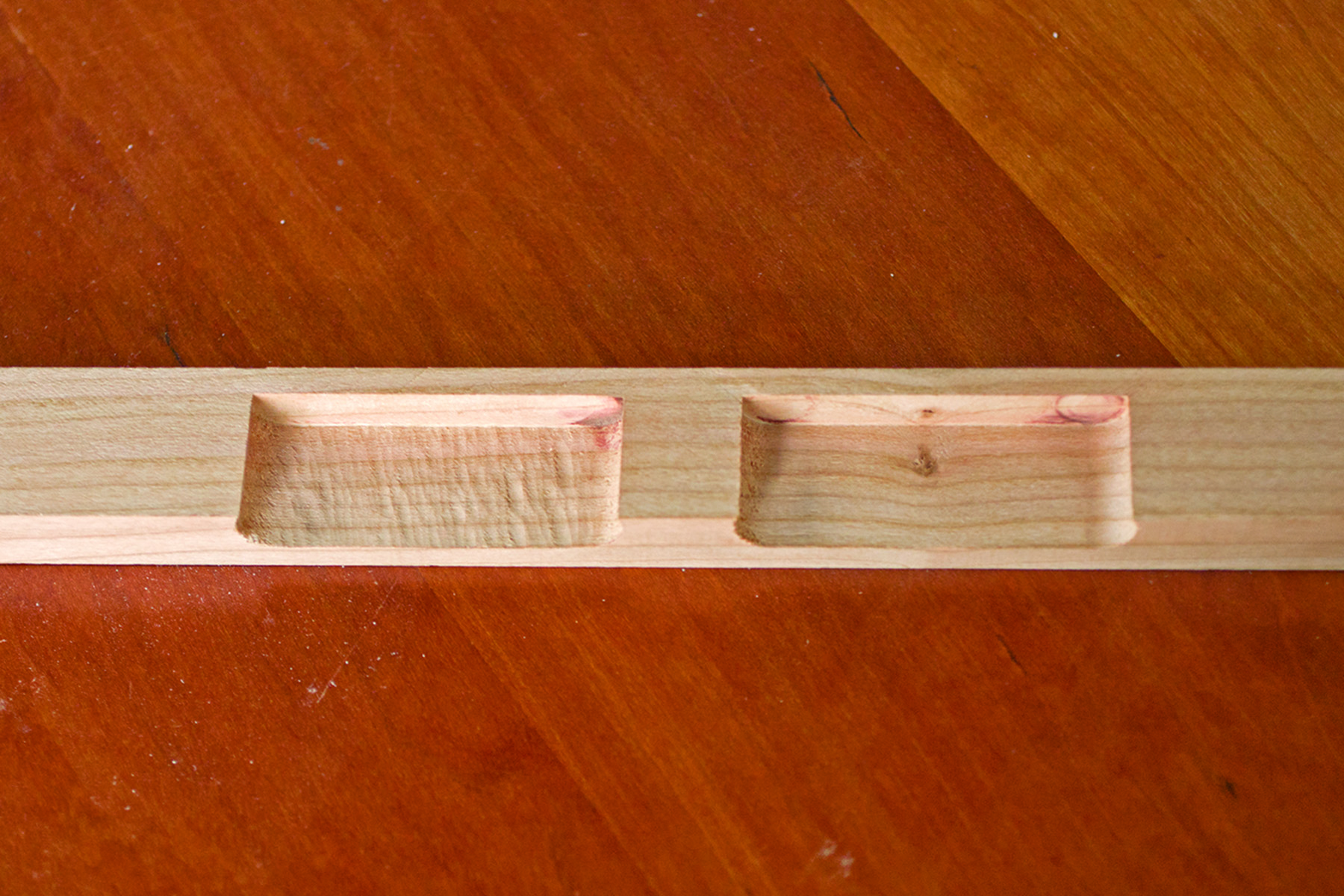

Too fast? If you cut too aggressively with a router, the results suffer. In the mortises above (which are sliced in half lengthwise), you can see chatter on the top. On the bottom is a mortise routed at an appropriate speed.

Hard work and accurate work seldom go together.

I’m not talking about your work ethic here. Rather, I’m talking about the idea that if you’re straining or pushing too hard or cutting too fast, you’re creating a whole slew of accuracy problems. This is as true with machines, where you’ll see vibration, chatter and torn-out fibers, as it is for hand tools.

And it’s also true for your body. You need to get a feel for how hard to push or how fast you can cut before things break down. And then find ways to work within those limits.

This doesn’t mean you can’t work fast and hard up to the point where accuracy matters and then slow down to get it all exactly right. It means that pushing for hard and fast has consequences for the accuracy and cleanliness of your cuts.

Stay Relaxed

It’s common to tense up when trying to learn a new way of doing something physical. Adding in the thought that you should relax is not always beneficial (although sometimes it helps). Instead, try to break down the task into smaller components and work on one simplified task until you can do it without tension. Then add in the next component. It’s particularly helpful to commit to working on muscle memory separate from accuracy and detail. Don’t stress about accuracy right away, either. It comes from a few things: using your body correctly and without added movement or tension, an awareness of exactly where you need to cut and experimenting to see how you can best put these things together. Then it takes practice. Sometimes lots of practice.

Seek Out Feedback

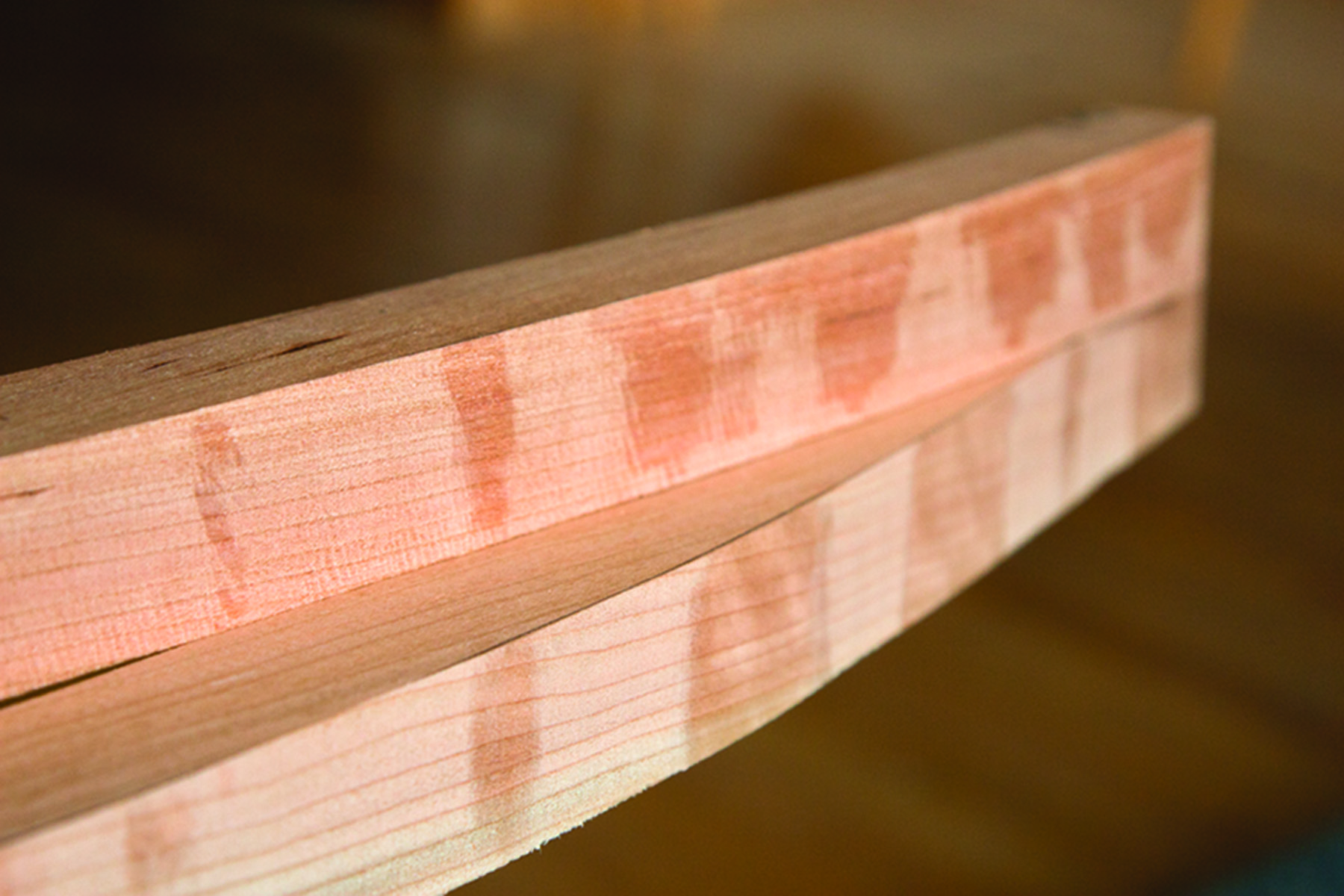

Plane feedback. Be sure to watch for the uneven removal of stock as evidence of planing out of square. You can see this on the top leg. The leg on the bottom is still square across.

It’s really helpful to have someone else look at your work, especially if that person is more skilled than you are. You need to learn to see more in the work, and having someone else point things out to you is an invaluable start.

But feedback should come much earlier than at the end of the project.

There’s a very rich stream of feedback available to you as you work. Your hands, eyes, ears and even nose provide you with all kinds of useful information. You need to pay attention to this feedback for a couple of reasons. First, not noticing what you’re doing as you do it, with all of the detail available, is like driving your car without paying attention to what you’re doing. You don’t wait until you’re in the ditch to correct your steering; don’t wait until your work is a mess before paying attention to your woodworking.

Second, the more you observe of the sights, sounds, feel and smell of woodworking as you go, the more you’ll be able to correlate certain feels, sights and sounds with success. How does the plane feel in your hand when it works especially well? How does it sound? What does it look like when you plane perfectly? What about the sound of the jointer or planer when you’re going against the grain as opposed to with the grain?

Make it a habit to pay attention to all of these things more and more, and your work will improve.

Learn at What to Look

It’s not as simple as it sounds. A lot of the time, the temptation is to watch something that is completely irrelevant. At the table saw, that might mean watching the blade cut the wood. Sure, you need to be aware of where the blade is so you can keep your hands away, but watching the blade cut won’t affect the quality of the cut. Watching to be sure that the board stays tight to the rip fence is far more important, and will have a direct impact on the cut quality. Likewise, watching the shavings coming out of a handplane is cool, but the edge of the board you’re planing will tell you much more about what’s going on (although the shavings can tell you if the blade is skewed in the plane, and you should check that each time you start planing). Choose to look at what’s important.

Learn to Accept Mistakes

No one wants to make mistakes. But fear of making mistakes, or trying to avoid them by avoiding new challenges that might lead to mistakes, means you won’t develop as quickly as a woodworker. Afraid you’ll spoil good wood? Use cheaper stuff.

Learn How to Practice

Practice. Planing a short board upright against a single bench dog is a good way to learn about balance and pressure when planing. Practice enough and your muscles will retain the knowledge.

You really can’t skip practice. You need to get good enough at basic skills before you can add in or move on to additional, more challenging skills.

For example, if you’re not already comfortable with your saw technique, then the simple fact that you’re trying to saw to a line will mean you have to concentrate on that, and your saw technique will likely fall apart. You need to get good enough at the motions of sawing that you can do it without thinking. This means you’ve established certain neural pathways that are ready to work even if they aren’t given much thought. This is sometimes called muscle memory. And the only way to get it is to practice.

It doesn’t take a huge amount of time, but all the reading in the world won’t do it. You can’t learn to ride a bicycle by reading about it, and woodworking is pretty much the same.

Editor’s note: This article originally appeared in the December 2012 issue of Popular Woodworking.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.