We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

I’m in the first steps of my Adirondack chair project, and it’s a lot of fun working with the rough-sawn cedar I bought from a regional sawmill. I jumped right into measuring and sawing the lumber to rough project lengths. That’s the first real step of any woodworking project, but I needed to brush up on how to measure wood the right way. Here are some tips.

How to measure wood for rough length and width

1. If the boards are already short enough for surfacing, surface both faces flat and to a uniform thickness. If not, crosscut your boards to very rough, workable lengths (final length plus 2″-3″) and then proceed with surfacing.

2. Inspect for defects and mark them with a lumber crayon. Even if you can’t see them, the ends of mill-length boards nearly always contain drying checks. Play it safe and waste the first and last inch.

3. Begin final layout by locating the largest pieces on the largest boards. Allow 1″ extra in length for the rough final cut. To reduce waste in this step, lay out long pieces on boards with relatively straight edges. Reserve short pieces for the boards with the most curve.

4. Joint one edge of each board so that it’s nice and straight. Your method will depend on the tools you have – a power jointer, a jigged table saw, a guided router or a handplane.

5. Now mark rough width. Allow at least 1/8″ over the final width for possible rejoining.

Crosscutting with the right tools

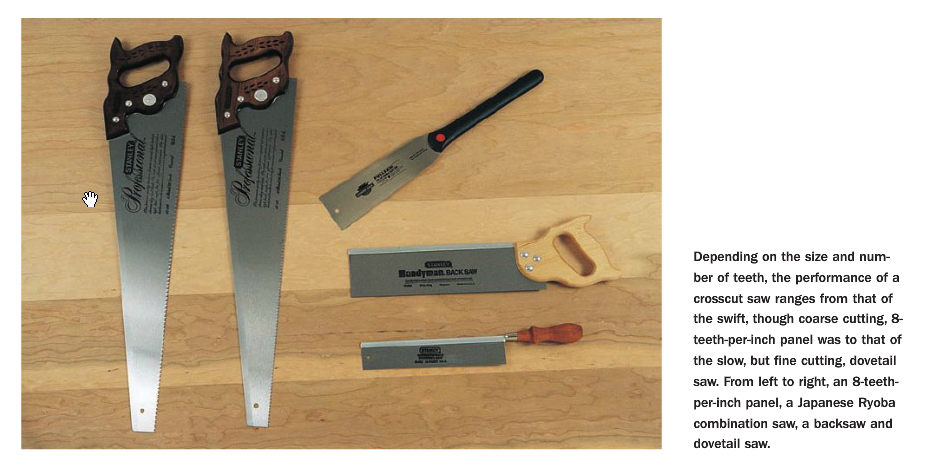

1. Start by choosing the right saw for the job. How fine a cut are you making? If you’ve been working on your craft for a year or so, chances are your handsaw kit includes all the options in this picture:

Do you have a power miter saw? That’s also a nice all-around tool.

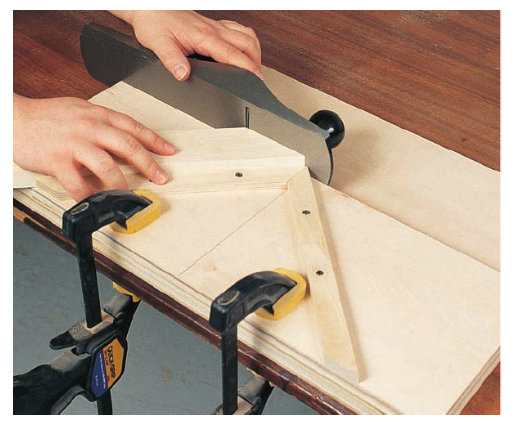

2. Don’t forget: a handplane is a crosscutting tool too. Use a shooting board to trim ends to exact length, on either a 90- or 45-degree angle.

3. Table saws are, of course, excellent tools for the same crosscutting tasks. If you have the money and inclination, buy and use these machines.

I’m relying heavily on professional woodworker Jim Tolpin for the tips above. He’s amazing. Buy Jim’s book “Measure Twice, Cut Once” for about 30 times more information on how to measure wood and optimize lumber for your projects. The book goes on sale next Wednesday, and it’s always available on our streaming ebook site.

Do you have anything to add? Please tell the community in our comments section below. Thanks!

–Dan Farnbach

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

Hi Dan,

Good luck on the chairs! I am a huge Jim Tolpin fan. I actually just bought that book and am waiting for delivery. I used to work in construction so I have some skills form there but I am just not used to dealing with anything less than 1/16, and honestly we often got buy working in 1/8ths. I hope this will help me raise my game and prevent gaps from almost perfect joints.

Other Tolpin books I really enjoyed were the New Traditional Woodworker and the Toolbox Book. Let us know how the chair goes.