We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Colm was one of the students at my Peters Valley live edge class and his table stood out both in terms of design and height. On the first day of class, he showed me an impressive looking walnut crotch slab and asked what I thought we could do with it. While discussing our options I showed him a recent live edge piece of mine, Mulberry Trio, and suggested that perhaps he could make an end or console table using three reclaimed bed legs that I brought to class with me.

Colm was one of the students at my Peters Valley live edge class and his table stood out both in terms of design and height. On the first day of class, he showed me an impressive looking walnut crotch slab and asked what I thought we could do with it. While discussing our options I showed him a recent live edge piece of mine, Mulberry Trio, and suggested that perhaps he could make an end or console table using three reclaimed bed legs that I brought to class with me.

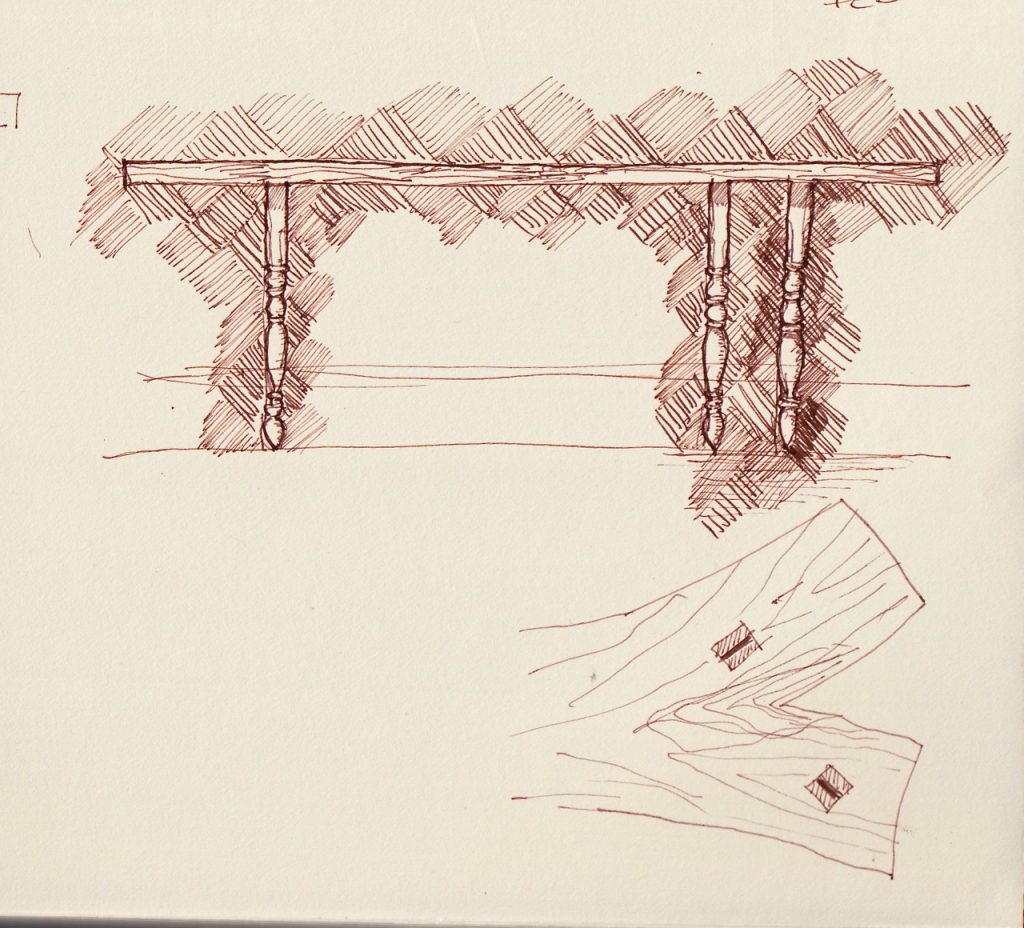

We concluded that because the slab was thick enough, we could reliably anchor the legs into it and eliminate the need for supporting stretchers or aprons while providing the table with adequate structural stability. A table like this is not intended to go through intense use, abrupt side forces or be subjected to heavy loads, and it is best placed near a wall in a house that is free of toddlers, monkeys or Pokemon Go players…

So here was our plan…

- Form three tenons, one at the top of each bed leg.

- Trim the pineapple finials so that the upside-down legs have enough footing to stand on.

- Create three mortises in the “Y” slab.

- Saw kerfs through each of the tenons.

- Make wedges for each leg.

- Glue the legs in, including the wedges.

- Saw off the excess on the tenons and wedges.

- Sand the table.

- Paint the legs.

- Apply an oil based finish on the whole piece.

This is one of four bed legs that I brought to Peters Valley to be used by my students. Originally they belonged to a bed that was trashed by one of our neighbors. I dismantled the bed and saved the legs. The headboard was unsalvageable as it was made from plywood and began to disintegrate from being left in the elements.

Colm placed each leg on the table saw sled, raised the blade to 1/2” height and crosscut dados in the tenon facets until a square tenon was formed. He used a stop block clamped to the crosscut sled to ensure reputable results and identical tenon lengths.

Next time I will show the next steps in his plan.

If you are interested in designing and working with live edge lumber, check out this previously recorded webinar from Yoav, “Urban Woodworking: Designing One-of-a-Kind Furniture” at shopwoodworking.com.

If you are interested in designing and working with live edge lumber, check out this previously recorded webinar from Yoav, “Urban Woodworking: Designing One-of-a-Kind Furniture” at shopwoodworking.com.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

![Working With Live-Edge Tops [Video]](http://www.popularwoodworking.com/wp-content/uploads/bfi_thumb/dummy-transparent-olcy6s63it1p9yp7uhusjas7c8kahafrhg9su7q9i0.png)