We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Say the name GRR-Ripper and most woodworkers who own a table saw know the product. It’s a great tool to use for ripping, especially when cutting thin strips or on odd configurations – I use the tool when I demonstrate making the chevron inlay for the spice box door from the December 2001 issue (#125).

Say the name GRR-Ripper and most woodworkers who own a table saw know the product. It’s a great tool to use for ripping, especially when cutting thin strips or on odd configurations – I use the tool when I demonstrate making the chevron inlay for the spice box door from the December 2001 issue (#125).

Building on the success of the GRR-Ripper, as well as finding another area in the shop where a tool such as this makes sense, Micro Jig has just introduced the GRR-Rip Block. Toss out your shop-made push block because Micro Jig has taken that basic design and made it one two three times better.

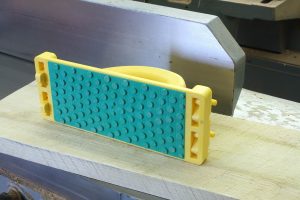

For one, the GRR-Rip Block has a handle that’s easy to grip, unlike the shop-made block we use here in at Popular Woodworking Magazine where your palm rests against and propels the block. But that’s easy to see. What makes this tool even better is the green non-slip, grippy material that covers its bottom – don’t think sponge-like (those push handles are pitiful). The pattern on the GRR-Rip Block is large enough to compensate for any small particles that try to hitch a ride over the jointer or through a saw cut, yet there is more than enough contact with the workpiece to guide and move it along.

For one, the GRR-Rip Block has a handle that’s easy to grip, unlike the shop-made block we use here in at Popular Woodworking Magazine where your palm rests against and propels the block. But that’s easy to see. What makes this tool even better is the green non-slip, grippy material that covers its bottom – don’t think sponge-like (those push handles are pitiful). The pattern on the GRR-Rip Block is large enough to compensate for any small particles that try to hitch a ride over the jointer or through a saw cut, yet there is more than enough contact with the workpiece to guide and move it along.

The real improvement Micro Jig made to the shop-made design, is the gravity heel hooks located at both ends of the GRR-Rip Block. These adjustable hooks fall down to catch the end of your workpiece, and the front hooks that come down on top of the workpiece simply push up flush with the tool’s bottom. When working on flat surfaces – jointer, router table or table saw – hold the tool with the handle directing your force inward, toward the fence.

The real improvement Micro Jig made to the shop-made design, is the gravity heel hooks located at both ends of the GRR-Rip Block. These adjustable hooks fall down to catch the end of your workpiece, and the front hooks that come down on top of the workpiece simply push up flush with the tool’s bottom. When working on flat surfaces – jointer, router table or table saw – hold the tool with the handle directing your force inward, toward the fence.

If you’re supposed to position the GRR-Rip Block a certain way, what’s up with the heel hooks being on both ends? When resawing lumber at a band saw, you can use the tool with the handle’s slight angle facing down or facing up. When you reverse the tool, you have gravity heel hooks where needed. And if you want the hooks to stay up out of the way all together, simply push them up until the lock. Way cool.

Here’s a short video that demonstrates the GRR-Rip Blocks in action.

I used a GRR-Rip Block as I milled lumber in the shop. I’m sold. You can grr-rab a couple of the Micro Jig GRR-Rip Blocks in the Marketplace at Woodworking in America October 18th & 19th at the Northern Kentucky Convention Center. (The marketplace – save a couple of bucks with an online registration – is open to the public , but you’ll need to register for the Woodworking Conference.) Do all of that here.

If you’re looking for a woodworking jig to improve upon to launch your company, or if you just want a couple of jigs that will improve your time in the shop, grab a copy of the CD “55 Best Shop-made Jigs.”

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.