We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

I prefer to use cut nails in reproduction work because they hold better and look right to my eye.

But when it comes to cut headless brads, which are used to hold moulding in place while the glue dries, I don’t think these nails are the right choice for me.

While cut nails are always more expensive than the equivalent wire nail, cut headless brads are crazy expensive. A 1 lb. box of the 4d nails that contains 576 nails costs $55.10, just less than a dime a nail. That might not seem expensive until you have to buy several boxes in a year (I do).

Compare that to the equivalent 18-gauge nail. You can easily get 1,000 nails for $4.72 – less than half a penny per nail.

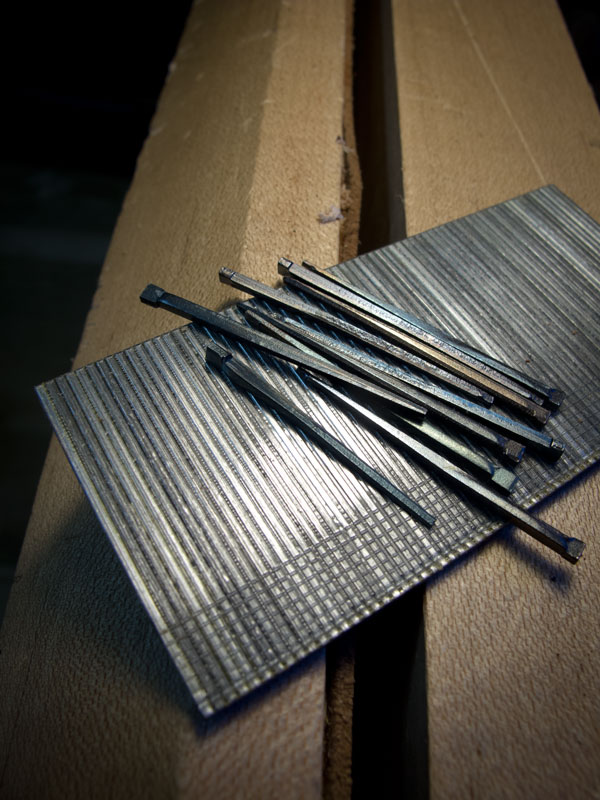

Wait, but don’t the 18-gauge nails look different than the cut headless brads? Yes, when sitting on the bench. But when the nails are sunk in the work, they both display an identical square head (see above). It is almost impossible to tell the difference.

Wait again. Don’t the cut headless brads hold better? Maybe. But it’s irrelevant when applying mouldings. The brad’s job is to be a clamp only. Once the glue is dry it is just a piece of metal in a piece of wood.

If you’re a purist, feel free to scoff and use the cut headless brads. I’m going to use my 18-gauge brad nailer and use the money I saved to buy some more beer.

— Christopher Schwarz

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

Chris – a pal found some cut nails in a ghost town in Nevada last week. One in the picture he sent has a “4” stamped into the end. I found a site Nailhunter http://nailhunter.ehost.com/ with .enough info to keep one clinched to the screen for a few days at least. So I’m guessing a height or distance marker. But someone could have found a box and used them for what ever.

Any hints/suggestions?

Thanks

John O

Oh the horror of it……

After all these years Norm was right,

I’ve contended for years that if our forefathers had electricity, compressors, and half the tools we have today, “the purists” would be saddened by reality. With the prospect of knocking out 1 piece a month they could instead make 4 a week, ummmmmmmmm, hold on there let me do the math.

Pocket holes, forgedddaboudit.

Festool, sheesh get out of my way, can’t you see I’m doing critical joinery here.

Pop, pop, pop, pop, pop………… Ok Boss I just finished the last of the trim here.

I don’t know about you Joshia, but since we put in the kiln, we’ve been able to joint and plane 3,500 bd/ft a week. Ya ya that 24″ planer really brings it down quickly, been using those stupid #8’s for door stops. Same as most of those other hand planes since we got the big jointer. Oh yeah sure, the helical heads are great.

Good thinking. Beer should always trump nails.

18-gauge is on the left.

Chris, I love reading your blog, even when, as a purist, it leaves me feeling torn, confused, or dirty.

pur·ist: noun \ˈpyur-ist\ : a person who has very strong ideas about what is correct or acceptable and who usually opposes changes to traditional methods and practices

I think the methods you present are great for today’s woodworker to consider, never making sacrifices to the end result to make things easier, faster, or more cost effective.

Do fine period pieces ever have the nail holes filled with filler or finish, making the look of the nail head less important or not important at all? I assume that most “country” or “non-fine” period pieces have completely visible heads.

Wow! I was afraid to admit I did this for fear of losing hand-tool-cred! I discovered this when I ran short of cut brads at the end of a project. If I’m feeling very hand-tool-y I still break them up and drive and set them with hammer and punch.

Makes total sense to me.

Even purists have to acknowledge the truth behind this.

(Well, maybe not…lol)

FYI Lee Valley sells cut nails, the 1-1/2″ headless brads are $9.70 for 1/4lb or $38.80 a pound, buy 5 or more and they’re as low as $35 a pound. Still not cheap but $20 a pound cheaper then you are buying them.

http://www.leevalley.com/US/hardware/page.aspx?p=40387&cat=3,41306,41324&ap=1

This works… I used 18 gauge brads on a piece I entered in a woodworking show. I sanded the heads to remove the coating before hammering them in. The piece was awarded a ribbon and people asked where I got the cut nails…

For this application, 23 guage slight head micro pins (Cadex I believe is the only source) Hold quite well until the glue dries, better than a straight micro pin, and the heads are so tiny they can bee hidden in the pores of a grainy wood or overlooked by those of us over 40 who can’t see up close. As a bonus (in addition to having bought the nicest pinner made) you get a nifty blowgun on the side of your nailer.. Not the same thrill as buying a new infill plane, I’ll admit, but eminently more practical.

I’ve read that the friction generated when a brad is driven in pnumaticaly melts the glue holding the nails together so that once the nail is seated the glue increases its holding power considerably. I don’t know if that is true or not but I do know that trying to remove those brads can be a real chore, even without any wood glue in the joint. I wonder if the cut nails would be better if you thought you, or someone else, might ever need to remove the moulding. Just a thought.

Jim

Wait, sometimes, moldings are fastened to a panel which grain runs perpendicular to that of the molding, in which case the molding is usually glued over the first couple of inches, and a couple of nails, which can bent slightly, are used to keep the rest of the molding attached to the panel. In that case, the holding power matters. Am I wrong?

Chris:

I am glad I was sitting as I read this… Seems you’re channeling your inner Norm! Next will be flannel shirts and a Boston accent…

As long as you don’t stain your mahogany cherry!

Dave

I use the 18 gauge brad nails, as well, but I’m an 18 gauge brad nailer purist, so I peel them off of the strip and hammer them in individually with a cross peen hammer that was baptized in Lake Superior under the light of a full moon in August.

You still can’t tell the difference, but it makes me feel superior.

Tried doing it with a hammer that was baptized in Lake Eerie once, but… it just made me feel creepy.