|

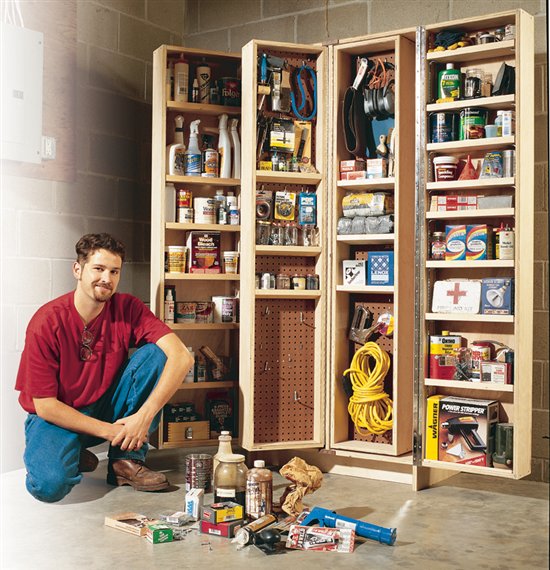

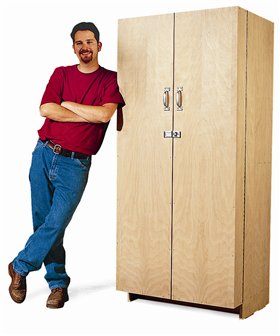

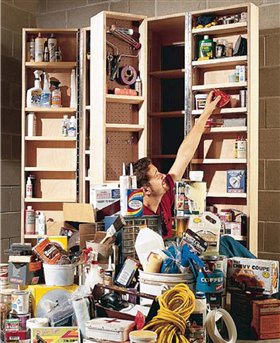

If your workshop seems cluttered and your

workbench is always covered with stuff,

you need this cabinet. It packs 30 cubic ft.of

storage, enough for all of those got-to-have

supplies, from screws to paint cans. Everything

is readily accessible, without reaching, because

the big pantry-style doors open wide. We’ve

packed a room-full of storage into a cabinet the

size of a fridge—only 30-in. wide, 24-in. deep

and 6-ft. tall. Best of all, this cabinet is easy to

build.You and a buddy could whip together a

couple of these beasts over a three-day weekend.

Tools and Materials

To build this cabinet, you’ll need a tablesaw with

a 30-in.-capacity rip fence and an outfeed table,

a dado set and a router with a 1/2-in. diameter

straight bit. You’ll also need a drill/driver, a

bunch of clamps, glue, lots of screws, a hinge bit,

a hack saw and help from a friend to cut the big

sheets of plywood.

All of the materials you need to build the

cabinet, except for the rare-earth magnet door

catches, are available at your local home center

(see Sources and Shopping List, below). You can save money by substituting AB exterior grade

plywood, but it’s considerably harder to

work with. Besides, it’s just plain ugly.

Standards and clips work great to

mount the shelves in the outer doors,

but you can also save a few bucks by mounting the ones inside the

cabinet with wooden cleats or by

drilling holes for shelf pins.

Getting Started

Measure the thickness of your

sheet stock before you start cutting.

It’s often up to 1/32-in. thinner than

you’d expect.The Cutting List below shows which pieces will be affected

if you’ve got skinny plywood. It’s best

not to cut these pieces until you need

them, so you can adjust the

dimensions.

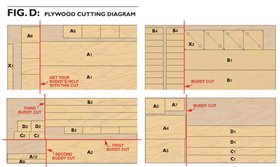

We’ve arranged the cabinet’s pieces

on the plywood so you can cut them all

to final size on your tablesaw, using

only the rip fence.You should recruit a buddy to help you make the first cuts in

each sheet (Fig.D “Buddy Cuts,”in red). If

you’re a lone wolf, it’s safest to make these

cuts with a circular saw and a straightedge.

The long pieces (cabinet sides, center

divider, door fronts and frame sides) are

arranged so you can cut them to exact

length from the short end of the fulllength

sheets (Photo 1). First, mark their

exact length on the plywood.Then,make

a second mark 1/8-in.beyond the first, to

mark the width of the saw kerf. Set the

fence to cut the distance from the waste

end of the plywood to the second mark.

Initial crosscuts leave most of the

cabinet’s long pieces cut to length. They

also result in manageable-sized pieces

that you can handle yourself. Crosscut

the remaining long pieces (one door

frame piece and the center divider) to

length the same way, from full-length

sections, after making an initial rip cut in

the fourth sheet of plywood. Convince

your buddy to stick around and help you

make these cuts, too.

Build the Cabinet

Rabbet the top and back edges of the

cabinet sides (Fig.A,Parts A1 and Photo

2).Then cut dadoes for the center divider

(A2) and fixed shelves (A3, A5 and A7). Perfectly fitting dadoes are easy to cut

with a router equipped with a 1/2-in.

straight-cutting bit, a spacer and a Tsquare

jig (Photo 3). Used on the second

pass, the 1/4-in. spacer makes a 3/4-in.-

wide dado. If your plywood is on the

thin side of 3/4-in., your spacer will have

to be thinner. Rout end-to-end dadoes for

the full-depth bottom shelf,and stopped

dadoes for the narrower middle shelves.

Every joint is glued and screwed.

Assemble the cabinet, using clamping

brackets (X2) to hold it square (Photo 4).

Then, fit the center divider and secure it.

Install the middle shelves. They’re offset

so both sides can be fastened to the center

divider.

Install the nail strip (A9), perf-board

back (A10) and fill strip (A11). The top

of the perf-board should be flush with the

top of the cabinet. Finally, install the toe

kick (A12) and glue on the door stops

(A13).

The Outer Doors

Rabbet the edges of the door fronts (Fig.

A,Parts B1).Fasten the frame sides (B2),

and add the ends (B3). Next, dado the

shelves (B4) to fit around the shelf

standards (Photos 5 and 6).Add a shim

to your dado set to allow a bit of side-to side

clearance for the standards.You have

to flip and re-clamp the pieces for each

pass. After all four dadoes are cut, glue

lips (B5),made from ripped-down 2×4

stock, on the shelf fronts. Then, use the

shelves to install the standards in the

doors. Be sure to push the standards to

the bottom of the door frame before

nailing so the shelves will sit level.

Clamp the doors to the cabinet so you

can install the hinges (Photo 7). Prop

the door in place on a simple stand.Then,

clamp it to a cantilevered straightedge

(use piece X1) and to the cabinet. The

straightedge ensures the door will be

flush with the top of the cabinet.

Clamping the door and cabinet sides

together removes any bow, so the door

will swing freely,once it’s hinged. A perfboard

spacer between the door and the

cabinet side creates room for the hinge

barrel.

When you’ve got the door positioned,

cut the piano hinges to length and install them, using sheet metal screws (Photo

8).Center the hinge between the edges

of the cabinet and door,with the barrel

facing you, and predrill holes for the

screws with a self-centering hinge bit.

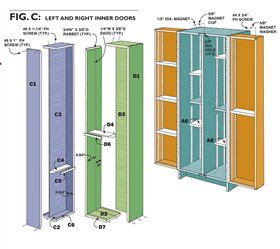

The Inner Doors

Rabbet the door frame sides (Fig. C,

Parts C1 and D1) for the ends (C2, D2).

Then cut dadoes in them for the perfboard

panels (C3, D3). Like plywood,

perf-board is often thinner than its

stated thickness. If yours is less than

1/4-in. thick, you’ll have to use a regular

blade in your tablesaw instead of your

dado set. Make two passes, adjusting

the fence between cuts.

Once glued in the dadoes, these perfboard

panels make the doors strong

and rigid. Hold the frames square when

you glue and screw the doors together.

Mounting the inner doors is similar

to mounting the outer doors, but the

hinges are fastened to the plywood faces

instead of the edges.

To prop the inner doors at the right

height, just stack two pieces of 3/4-in.

plywood (door shelves work great) on

top of the little stand used for mounting

the outer doors.Tape an 11/16-in.-wide

perf-board spacer to the front edge of

the center divider. Position the door

against the front of the cabinet,opened

180 degrees and resting on top of the raised-up stand. In this position, the door you’re

mounting will cover the opening on the opposite

side of the cabinet and its hinge side will be flush

with the hinge side of the center divider. They’ll be

separated by the spacer.

Hold the door against the spacer and cabinet with

a clamp at the top. Center the barrel of the hinge (with

the barrel facing you, just like on the outer doors) in

the space between the door and cabinet and install

one screw on each side, in alternating holes. Then

install a couple screws at the bottom of the hinge,

using knee pressure to hold the door against the

cabinet.With the hinge secured top and bottom,

finish installing the hinge screws.

Finishing Touches

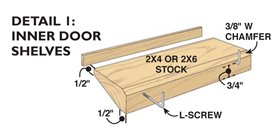

Notching the cabinet’s adjustable shelves (Fig. C,

Parts A6 and A8) makes it easy to mount the shelf

standards in the cabinet. You can also add shelves

made from 2×4 and 2×6 stock to the perf-board

doors (Fig.C, Detail 1). Fasten lips (B5, C5,D6 and

D7) to all door-mounted shelves.

Mount the door handles, rare-earth-magnet

catches (two per door) and the latch. Move the

cabinet into position, level it and anchor it securely to

the wall. Then get organized.

Sources

(Note: Source information may have changed since the original publication date.)

Lee Valley Tools Ltd., leevalley.com, 800-871-8158, Rare-Earth Magnet Catch Sets (4 required),

1/2-in. dia. Magnet, #99K31.03, $.82 each;

5/8-in. dia. Magnet Cup, #99K32.53, $.59 each;

5/8-in. dia. Washer, #99K32.63, $.59 each.

Cutting List

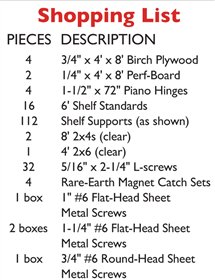

Shopping List

This story originally appeared in American Woodworker December 2001, issue #91.

December 2001, issue #91

Purchase this back issue.

|

|

Click on any image to view a larger version

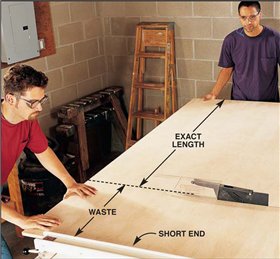

1. Cut the cabinet's long pieces from the short end of

full-sized sheets.You’ll need a buddy to help maneuver the

ungainly sheet and keep the big offcut under control.With

careful measuring, the cut-off piece will be exactly the right length,

ready to be ripped to width.

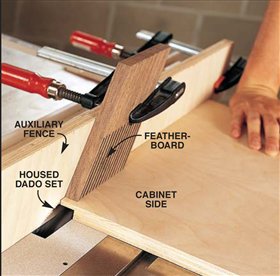

2. Rabbet the cabinet sides for the top and back,

using an auxiliary fence (Part X1) and a featherboard.

By housing the dado set, the fence allows you to

match the width of the rabbet to the thickness of the

plywood top.The featherboard acts as a blade guard and

ensures a consistent depth of cut.

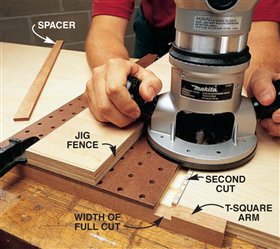

3. Rout perfect dadoes for the shelves

with a 1/2-in. straight

bit and a T-square-style

jig made from scrap.

Make the wide dado in

two passes, the second

with a spacer held

between the jig’s fence

and the base of

the router.

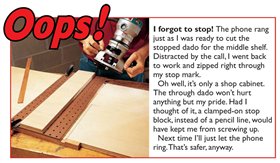

Oops!

4. Plywood clamping brackets keep the cabinet square and let

you glue and screw it together, one side at a time, without big pipe clamps.

We’ve included the eight brackets you need in the plywood cutting diagrams

(Fig.D, Parts X2).

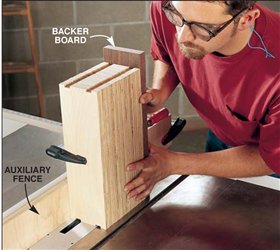

5. Gang the shelves together for dadoing. A

backer board keeps

the dado set from

blowing out the backside

of the last shelf.

The auxiliary fence’s

extra height keeps the

stack steady.

6. Nailing the standards is a cinch

because the dadoed

shelves hold them in

place for you. Needlenosed

pliers are much

better nail-holding

devises than your

fingers!

7. Clamp the doors in position before installing the hinges, using a shop-made

stand, a perf-board spacer and

a straightedge extending from

the top of the cabinet. Make

sure the edges of the door

and cabinet are flush.

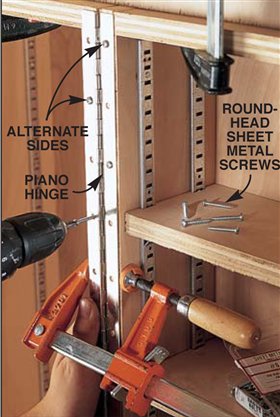

8. Mount the hinges with sheet metal screws. They

have sharp threads that grip much

better than the puny screws supplied

with the hinges.Alternate the screws

between the cabinet and the door so

their heads won’t bind.

You won’t

believe how

much junk

you can fit

into this

amazing

cabinet.

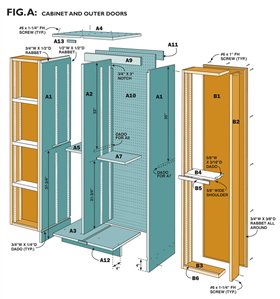

Fig. A: Cabinet and Outer Doors

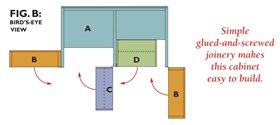

Fig. B: Bird's Eye View

Fig. C: Left and Right Inner Doors

Detail 1: Inner Door Shelves

Fig. D: Plywood Cutting Diagram

|