We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Editor’s note: This article originally appeared in the April/May 2013 issue of American Woodworker

When I came to America eight years ago, I was able to get a work permit and a job at LA Fitness because I’d earned a license as a personal fitness trainer in my hometown of Ciechanów, Poland. I’d also learned woodworking there from a master woodworker who was also a two time Olympic gold medalist in weight lifting.

Unfortunately, when the economy turned sour in 2008 I lost my job and had to make changes. I moved from Connecticut to Pennsylvania, where it’s much cheaper to live, and was lucky to find job in the woodworking industry. Shortly thereafter, I began to think about having my own shop. My grandpa always told me, “If you can’t pay in cash, you can’t afford it.” So I saved for several months before buying my first stationary tool, a molder/planer, which I had to store in my living room. Slowly, I acquired more tools and eventually I found a 1000 sq. ft. shop space that I could afford.

I started my woodworking business in my spare time by making small pieces free of charge for my new neighbors and friends. I also remodeled my kitchen and built almost all my furniture as well as the equipment for my home gym. (Like my woodworking mentor in Poland, I’m a weightlifter—my friends call me “Big John.”) My first serious job was to modify an old TV cabinet to fit a new plasma TV. Reducing the cabinet’s depth was challenging because of its moldings and frame-and-panel structure, but my customer was happy with the results—and I was convinced that starting my woodworking business was the right decision.

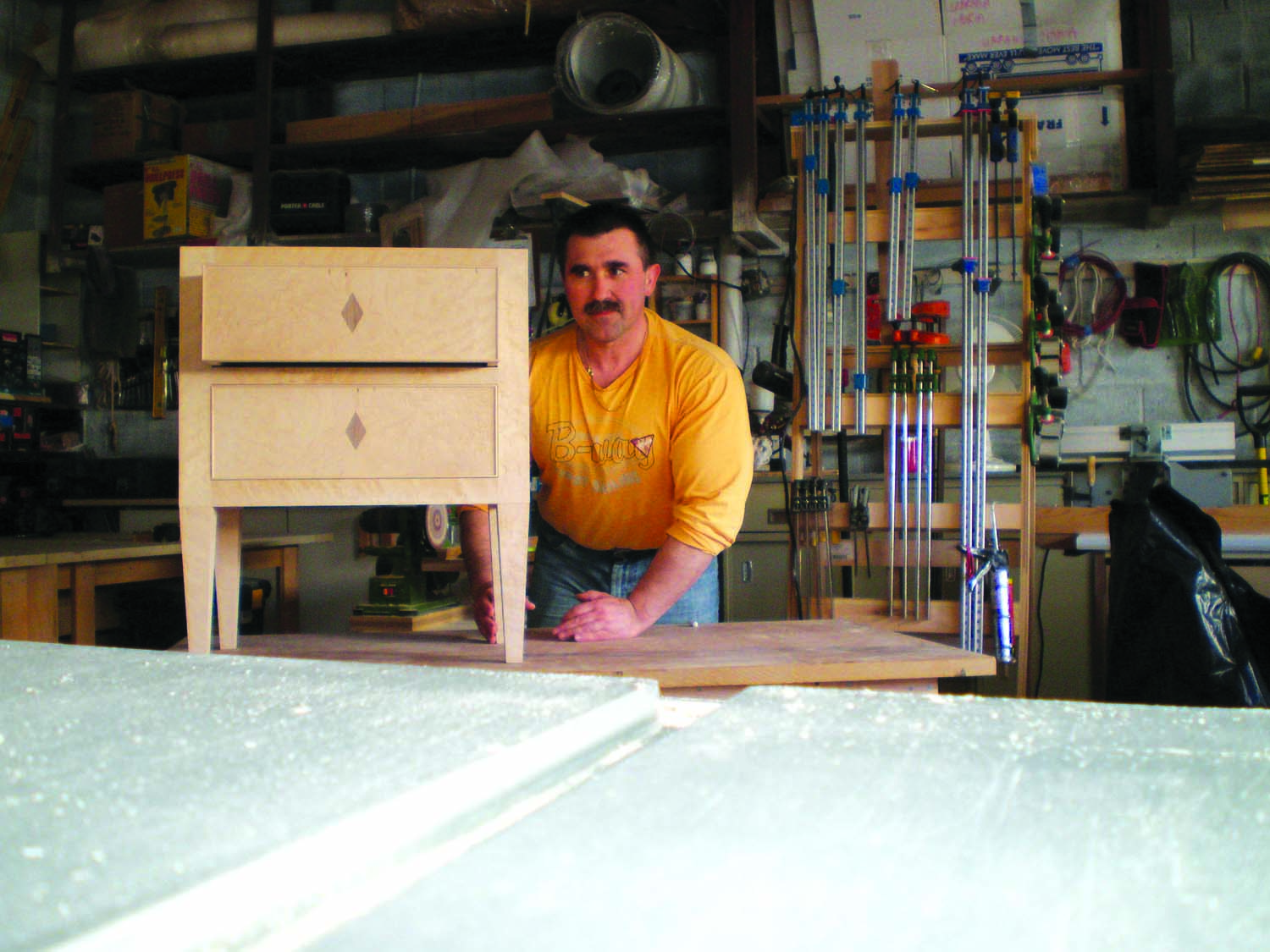

Then as now I read many woodworking books and magazines, so I was always learning new things at home and on the job. (Currently, I’m studying 3D design.) Every day after work I made something for my shop, using salvaged materials as often as possible, to save money. I built racks to store my tools and shop supplies, a lumber rack and a large workbench. As money allowed, I upgraded my tools by trading used for new or for better quality. Thanks to the training I received in Poland and here in America, I can build furniture in almost any style. I don’t try to compete with pieces that are mass-produced. My customers expect top quality work and I bend over backwards to satisfy them, because I’ve learned that word-of-mouth is my best advertising.

Starting a business in a bad economy wasn’t easy and it’s still tough now, but I’m optimistic about the future—I buy goods that are made in the USA whenever I can, because I believe this helps to create jobs and that some of the money will eventually come back to me through customers. I’m not a hero, just a regular Joe who’s trying to make this country a little bit better every day as I try to make my American Dream come true. God bless America!

John Pustelnik Wilkes-Barre, PA

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.