We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

by William Mikus

My woodworking career began at age 7, in 1935, cutting out lawn ornaments from grocery store boxes and crates with an old coping saw. Paint was the only expense. My inspirations were my father, who was a farmer (and by necessity a carpenter) and my older brother, who was an aspiring woodworker. I grew up reading The Deltagram, The Home Craftsman and Popular Science, Popular Mechanics, Mechanics Illustrated and Science and Mechanics. In those days, all of these magazines had woodworking articles in them—they were the woodworking magazines of that era.

I bought my first woodworking machinery in 1946, shortly after graduating from high school. My father co-signed the loan. It was all Delta equipment—I have some of the machines to this day. I set up shop in a former chicken coop on my father’s property in Aurora, Illinois and went into business building cabinets for the post-WWII housing boom. During this period I also built several wooden boats.

Business was good. Life was good. Then came the Korean War. After a stint in the army, I resumed the business and attended college. Then my shop caught fire and I lost almost everything.

Business was good. Life was good. Then came the Korean War. After a stint in the army, I resumed the business and attended college. Then my shop caught fire and I lost almost everything.

I replaced all the machinery by buying out another woodworking shop and built a new 30′ x 40′ two-story building (#1, pre-shop), with a shop on first floor and living quarters on second. Eventually, though, I went out of business, so I could pursue my vocation of architecture as well as other interests. I sold most of the machinery and converted the building into apartments.

I replaced all the machinery by buying out another woodworking shop and built a new 30′ x 40′ two-story building (#1, pre-shop), with a shop on first floor and living quarters on second. Eventually, though, I went out of business, so I could pursue my vocation of architecture as well as other interests. I sold most of the machinery and converted the building into apartments.

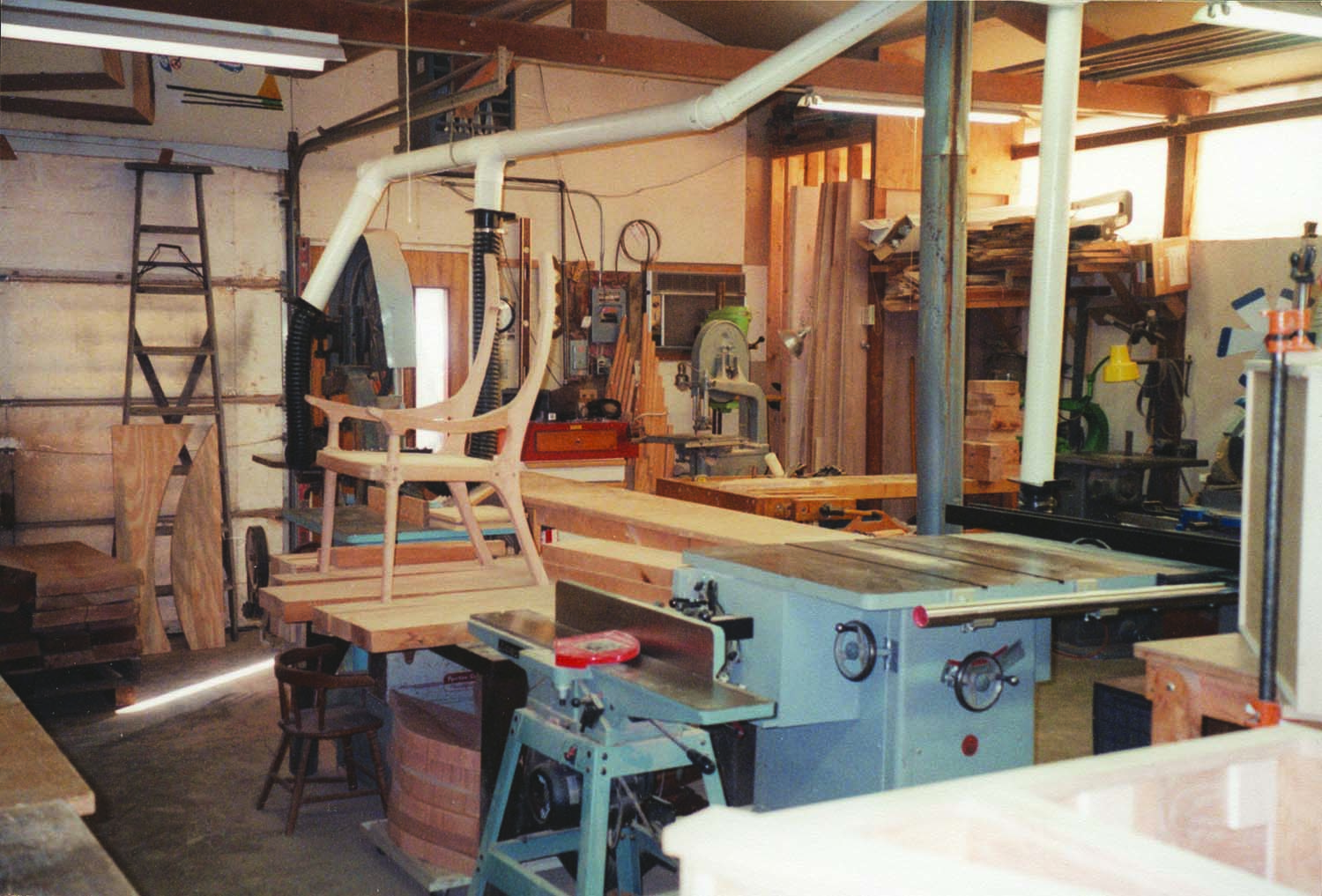

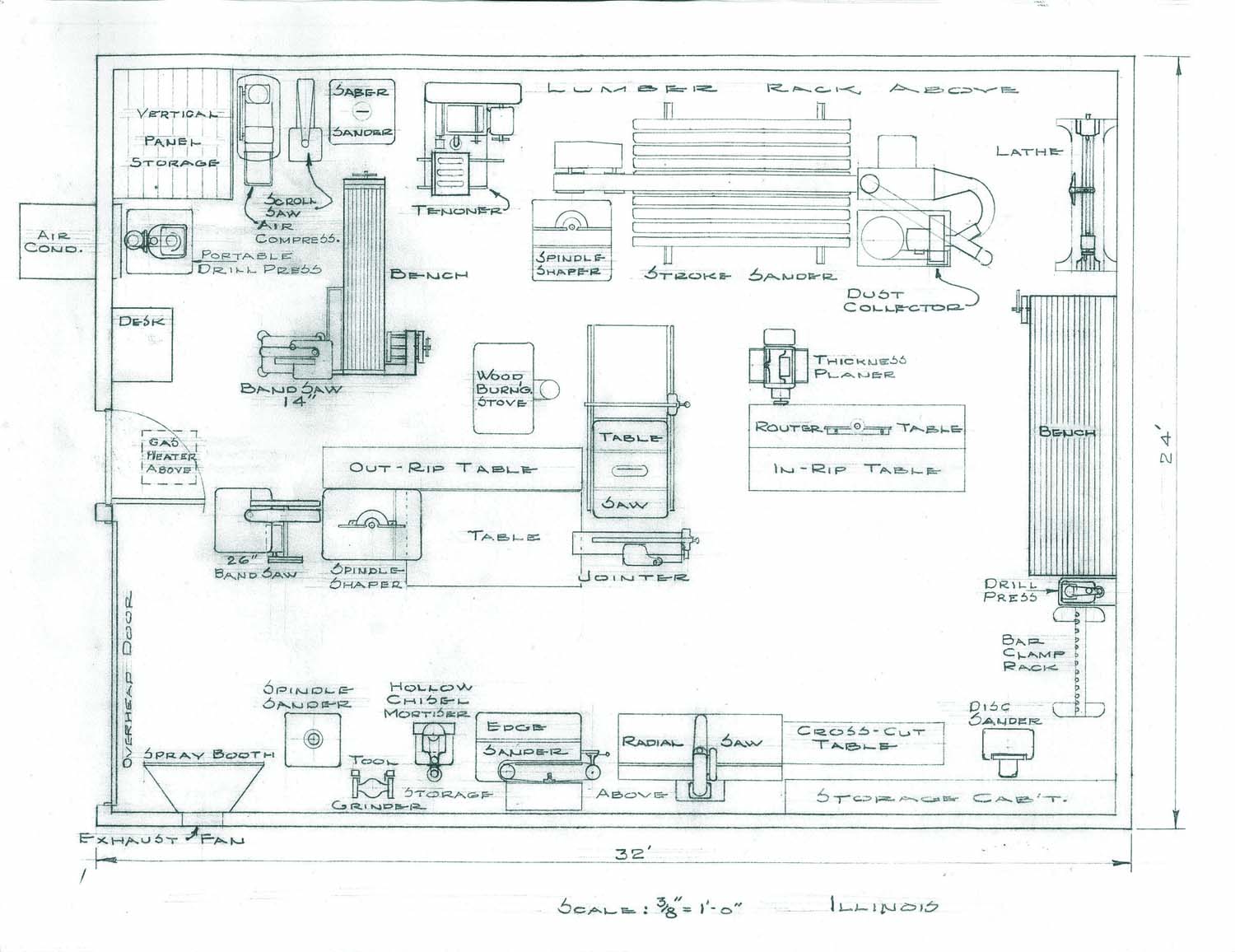

When my two sons grew up and showed an interest in woodworking, I built a new house in a rural area outside of Yorkville, Illinois, along with an adjacent 24′ x 32′ shop building. Once again, I began to acquire woodworking machinery. There were many woodworking machinery auctions in the Midwest at this time, so it was easy to find good equipment at reasonable prices. The same could be said about walnut trees—I obtained one particularly large specimen and had it milled with a portable bandsaw mill. I continued woodworking, building mostly furniture, selling through galleries and on commission.

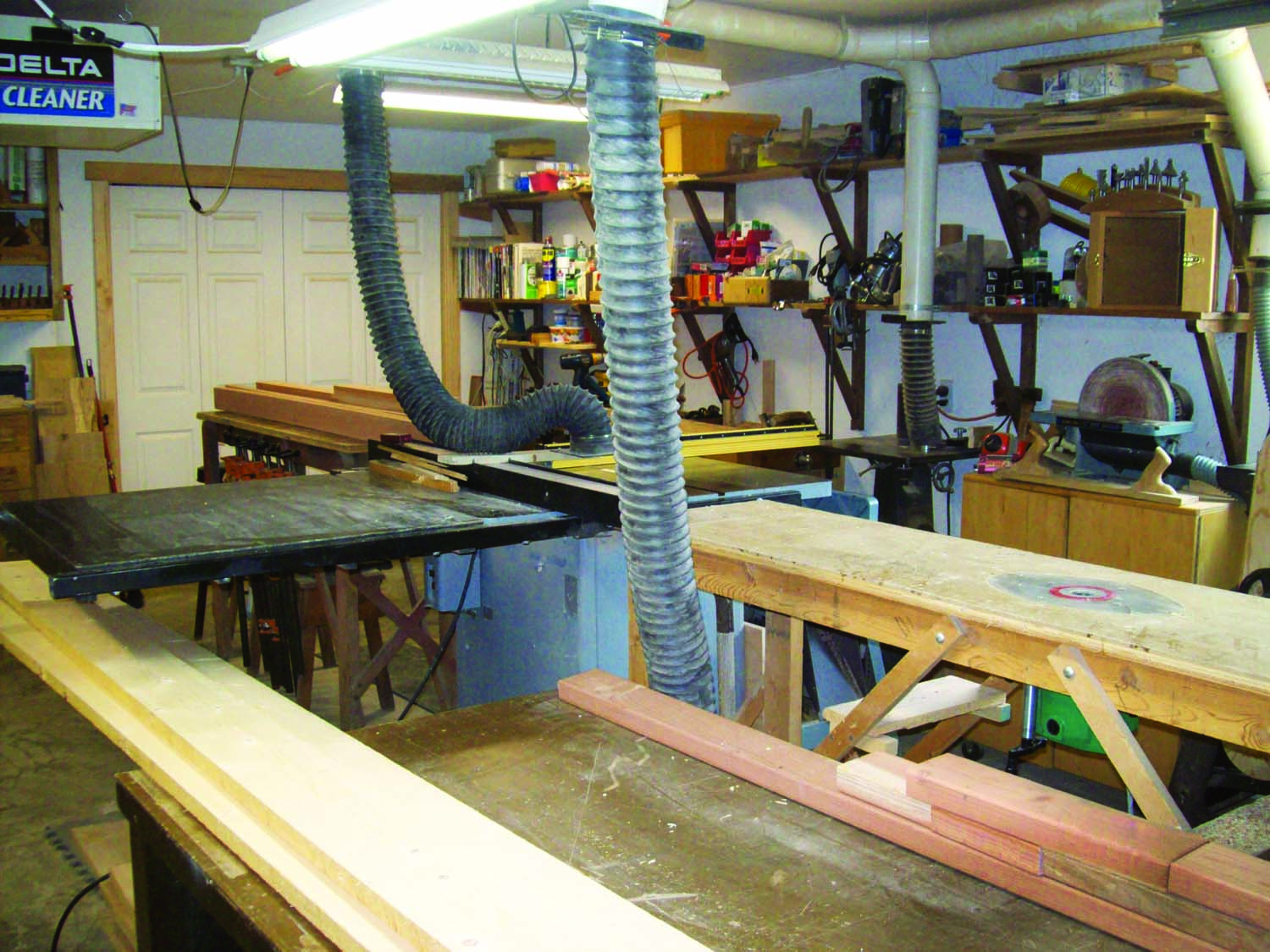

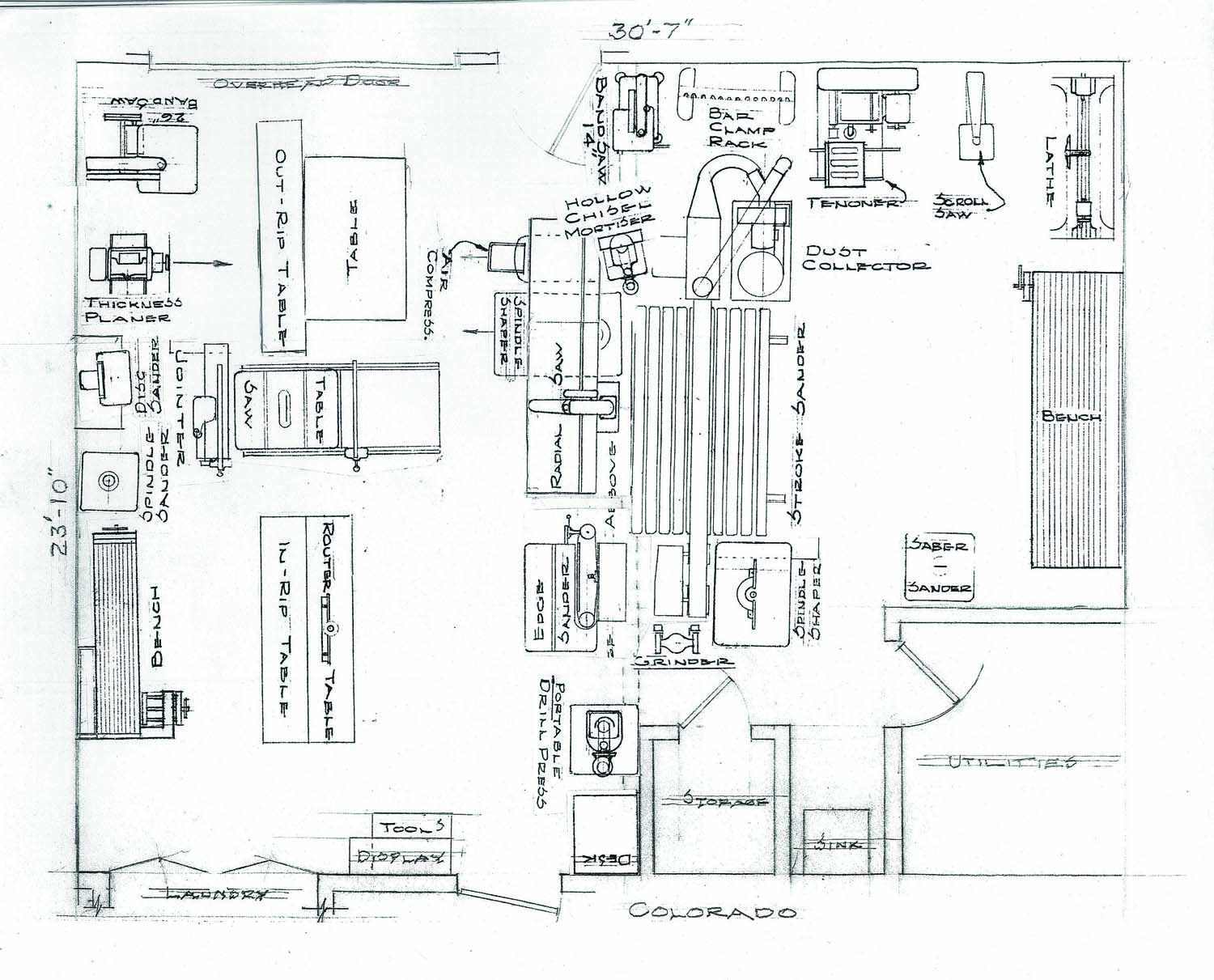

In 2003, when my wife and I decided to move to Colorado, my first thought was to sell all of my equipment, as I was in my mid 70s. But I quickly learned that although many woodworkers say they want the “good-old” cast-iron machinery, few (if any) are willing to pay for it. So when we moved, the machinery came along. This turned out to be a good thing, because after we relocated I used the equipment for many home-improvement projects. I also discovered an arts-and-crafts gallery in which to showcase my work in a town only 10 miles away.

We lived in our trailer while looking in vain for a suitable property with a house and a separate shop building. Eventually we settled for a house with an attached 3-car garage. The vehicles could stay outside.

Although the space is slightly smaller, this shop has worked well. One notable advantage is that the overhead door’s proximity to the tablesaw’s outfeed table has reduced the amount of lifting I have to do—an important consideration for aging woodworkers. After backing up to the overhead door, I simply slide the lumber and sheet goods out of my van, onto the outfeed table, across the saw table and onto the infeed table, ready for cutting.

Although the space is slightly smaller, this shop has worked well. One notable advantage is that the overhead door’s proximity to the tablesaw’s outfeed table has reduced the amount of lifting I have to do—an important consideration for aging woodworkers. After backing up to the overhead door, I simply slide the lumber and sheet goods out of my van, onto the outfeed table, across the saw table and onto the infeed table, ready for cutting.

Since moving here I’ve built additional cabinets for the kitchen, using hard maple from my daughter’s farm in Indiana, a bookcase and numerous smaller projects. I also built a greenhouse/solarium using 2×6 and 4×6 Douglas fir. All of the components were cut and machined in the shop before being taken out and assembled. This was fine woodworking on a large scale!

At age 85 I sometimes think of retiring … but there’s that stack of soft maple I have stashed. It would make a great bedroom suite for my granddaughter in Indiana. I also want to share my experiences by writing about the jigs, fixtures and machines that I’ve built over the past 78 years.

Over the years I’ve built boats, cabinets, canoes, furniture, architectural millwork, knick-knacks, and everything else in between. I’m proud of the diversity of my work; I never got into a rut doing just one thing.

William Mikus

Crawford, Colo.

Floor plan of the author’s Illinois Workshop

Floor plan of the author’s Colorado Workshop

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.