We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Washcoating. This blotchy pine board shows the impact of thinning a washcoat to various degrees before applying a stain. Left to right are sprayed full-strength lacquer, lacquer thinned 1-to-1 with lacquer thinner, 1-to-2, 1-to-3 and finally 1-to-4. It’s clear that getting the mix optimized for maximum color and minimum blotching is no easy matter.

Understand the difference between these often misused terms.

It would be difficult to find wood finishing subjects that have been made more confusing than sealing and washcoating. This is unfortunate because these procedures are very simple and easy to understand.

Definitions

A sealer is the first coat of finish you apply to the wood. It enters the pores, dries and stops them up so liquids don’t penetrate easily. It “seals” the wood. The sealer can be the finish itself (any finish), or it can be a special product designed to solve a problem.

A washcoat is any finish thinned to 10 percent-or-less solids content and used to partially stop up the pores in the wood (so a stain will still add some color), or provide a thinner barrier between color coats (stain, glaze, filler or toner) to limit the total finish build. The commercial varnish product labeled “wood conditioner” is a washcoat.

Finishing Steps

The steps for getting good results with any finish are as follows:

1. After preparing the wood, apply the first coat – by definition, the sealer coat.

2. Let the coat dry.

3. Sand this coat smooth so subsequent coats will be smooth (the first coat is always a little rough).

4. Remove dust and apply the next coat.

5. Apply as many more coats as you want. Sand between these coats if there are problems or roughness you want to remove.

Use the finish itself for the first coat unless you want to avoid one of two problems: the finish you’re using for final coats clogs the sandpaper, or there’s something in the wood that you want to block off. Use sanding sealer to avoid the clogging. Use shellac to block off problems.

Sanding Sealer

Oil-based polyurethane and all water-based finishes sand and powder easily without clogging sandpaper, but varnish and nitrocellulose lacquer gum up sandpaper. So manufacturers provide a special product to be used under varnish and lacquer, properly called “sanding sealer,” but sometimes misleadingly labeled “sealer.”

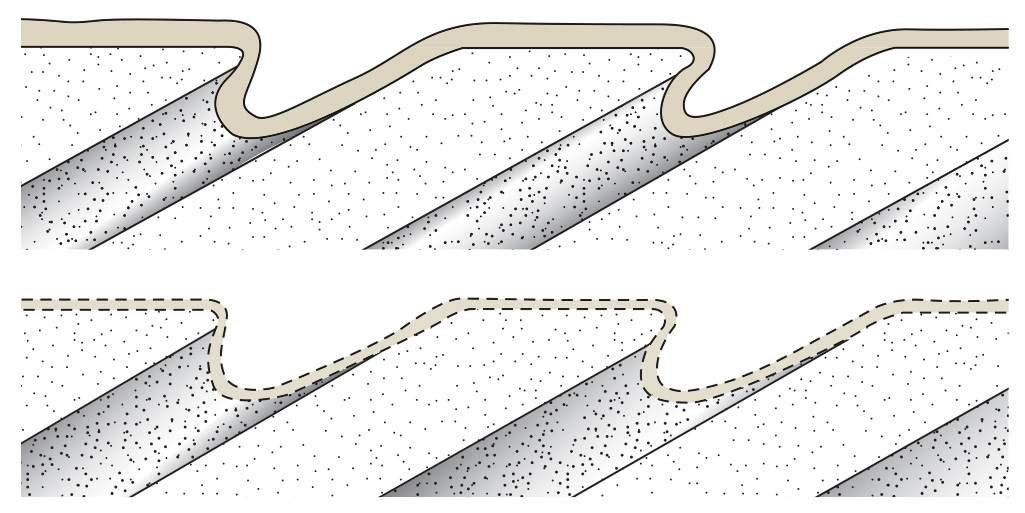

Sealing & washcoating. Sealing is the first full coat of any finish. It stops up the pores of the wood so liquids don’t penetrate easily (top). Washcoating under a stain with a thinned finish partially stops up the pores so some stain can get through (bottom).

The purpose of sanding sealer is simply to speed production. It takes significantly less effort (and less sandpaper) to sand large surfaces.

But sanding sealer reduces the durability of the total finish build because it doesn’t dry as hard or as water resistant as the finish itself, and subsequent coats of finish don’t bond as well to the sealer as they do to the wood or to previous coats of finish. So more is lost than gained by using sanding sealer on smaller objects.

Clogging. Lacquer and varnish clog sandpaper, even stearated sandpaper, which slows the sanding process and forces you to use more sandpaper.

Shellac is often recommended for sealing, but it adds little in the way of reduced sandpaper clogging. Shellac still clogs sandpaper, just less than varnish and lacquer.

Some manufacturers provide a sanding sealer for water-based finishes, but I see only disadvantages because water-based finishes are already easy to sand.

For easier sanding without using sanding sealer, thin the first coat of finish by about half so the build is thinner. The thinner the build, the easier the finish sands and powders.

Sealers Aren’t Primers

It would be easy to think of sealers as equivalent to primers for paint. They’re both first coats, after all. But sealers and primers have very different purposes.

The best paints hide well because they contain a high ratio of pigment to binder (finish). As a result, they don’t bond very well to porous wood. So primers, with a higher ratio of binder to pigment (and reduced hiding), were created for the first coat.

In contrast, finishes are all binder, so they bond perfectly well to wood. Finishes don’t need a separate product to achieve a better bond.

— BF

Shellac

Powdering. Lacquer and varnish sanding sealer powder when they are sanded. So do oil-based polyurethane and water-based finish. Shellac still clogs a little.

Shellac is often promoted as the “best” sealer. This is silly, as explained above. All full-strength finishes seal the wood.

Shellac’s benefits to the finsher are that it is unique for its blocking qualities. It blocks, or “seals in,” very low-surface-tension silicone oil from furniture polishes, which causes “fish eye” (the finish bunching up into craters or ridges). It also blocks odors from animal urine and smoke, and residue wax from waxed furniture or from strippers (many of which contain wax).

These are all refinishing problems, not new-wood problems.

Fish eye. Shellac blocks silicone oil from furniture polishes (right), which causes fish eye (left). Shellac also blocks other common refinishing problems such as resin from pine knots and oily tropical woods.

On new wood, shellac also blocks the resin from pine knots and very oily tropical woods, which can slow the drying of lacquer and varnish significantly.

Shellac is great for dealing with these problems. But if you are finishing new woods other than pine or very oily wood, shellac’s only benefit would be to add a little warmth to the color under water-based finish. The same thing could also be achieved with any solvent finish.

Washcoats

A washcoat is any finish thinned to 10 percent-or-less solids content: lacquer with at least 1½ parts thinner; varnish thinned with at least two parts thinner; or a ¾-or-less-pound cut of shellac.

Washcoats are used to partially stop up the pores of the wood to reduce blotching and to create a thin barrier between color layers so the colors don’t smear or mix. Used as a barrier, the washcoat is usually sprayed.

It’s confusing and wrong to call washcoating “sealing,” as is commonly done, because you’re not sealing anything.

Washcoating Under a Stain

If you’ve ever used a wood conditioner to prevent blotching, you know how difficult it is to achieve success. Besides the instructions on the cans being incorrect, you lose a lot of the stain’s color intensity and you usually still get blotching anyway. (The can’s instructions say to apply a stain within two hours, but to be fully effective you have to give the thinned varnish at least six hours to dry completely.)

Washcoating to reduce blotching is a trade-off. The higher the solids content of the finish and/or the more washcoat you apply (and let dry), the more you reduce the blotching but the lighter the resulting stain color. Successful washcoating takes practice, meaning experimentation, to optimize the ratios and application methods.

Factories usually achieve a darker coloring on blotch-prone woods such as cherry and birch using glazes and sprayed toners applied over a sealed surface. They put most of the color in the finish rather than in the wood. (This is why it’s almost impossible to imitate many factory finishes with only a stain and finish.)

Because of the instructions, which almost guarantee failure, and the resulting confusion the product causes, the woodworking community would probably be better off if wood conditioners were removed from the market.

Check out all of our articles on finishing available online.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.